Electrophoretic buffer

A buffer and electrophoresis technology, which is applied in material analysis, nanotechnology, immunoassay, etc. by electromagnetic means, can solve problems such as difficult injection, time-consuming, and sensitivity of buffer viscosity to temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] modulation polymeric micelles

[0134] Make ethylene glycol 130mmol, 6.5ml and dry THF 30ml, 2-methoxyethanol 0.16ml, naphthalene potassium (Naftarencarium) 1mmol polymerize at 25°C for two days, and then add 3,6-dimethyl 1,4 - 32 mmol and 31 ml of dioxane-2,5-dione were polymerized together at 25° C. for 2 hours, and then 20 mmol and 3.6 mL of methacrylic anhydride were used to terminate the reaction. Purification by reprecipitation was carried out in 600 mL of cold isopropanol, precipitation was carried out by centrifugation, and the product was recovered. This product was dissolved in 100 mL of benzene, freeze-dried and recovered to obtain 2.5 g of a copolymer. 2.5 g of the obtained copolymer was dissolved in 1000 mL of water, kept at 80° C. in an oil bath, heated while stirring for 6 hours, and left overnight after heating to recover the micellar solution. After 30 minutes, thermal polymerization was performed for 20 hours while maintaining 10,000 mL of the obtain...

example 1

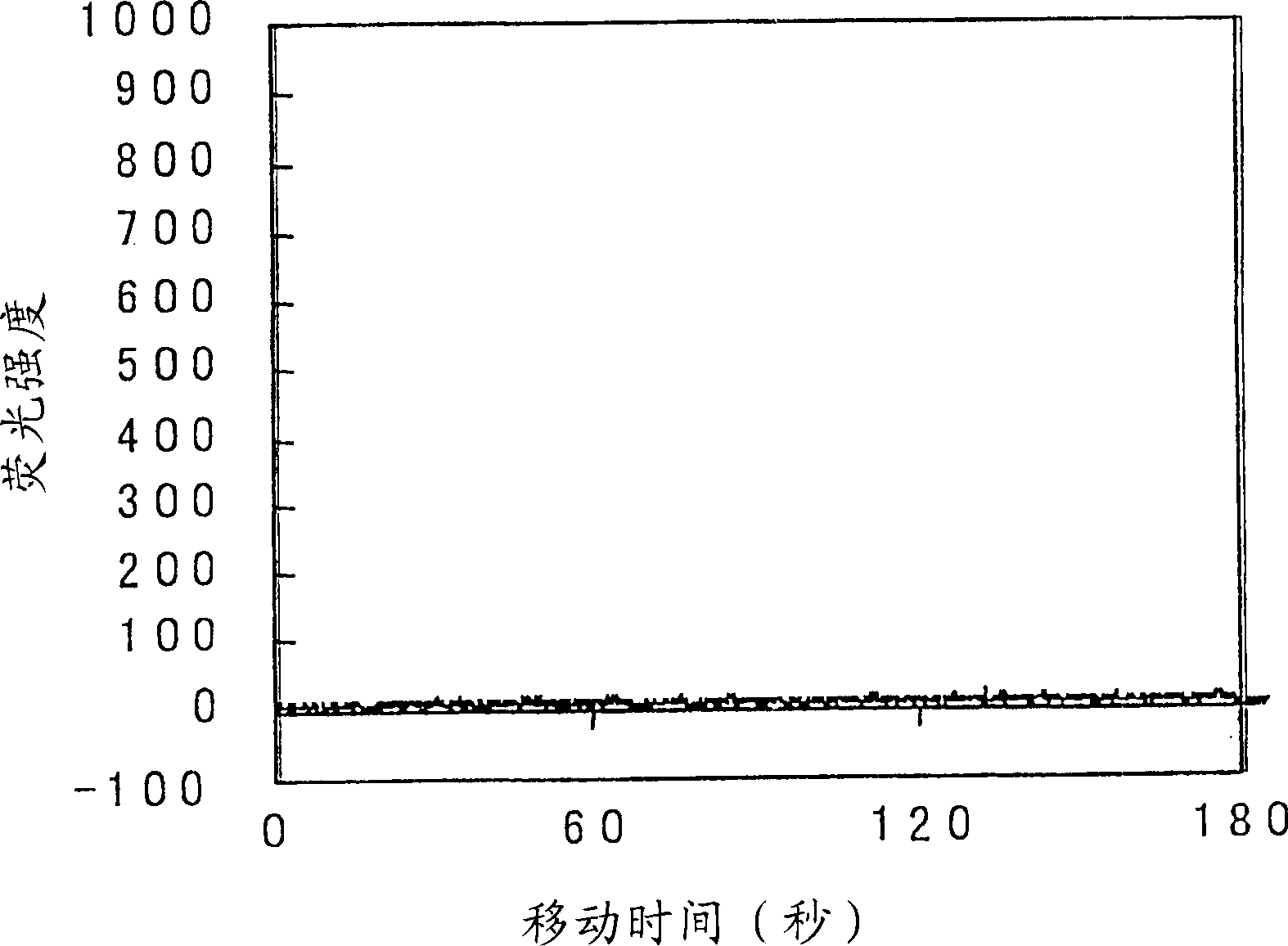

[0154] Example 1 (polymer micelles + common method)

[0155] Using high molecular weight micelles as the buffer for electrophoresis, electrophoresis was performed according to the ordinary method, and the two DNA markers of 100 bp and 800 bp were separated. As a result, no peak appeared within the migration time of 180s. ( figure 1 )

example 2

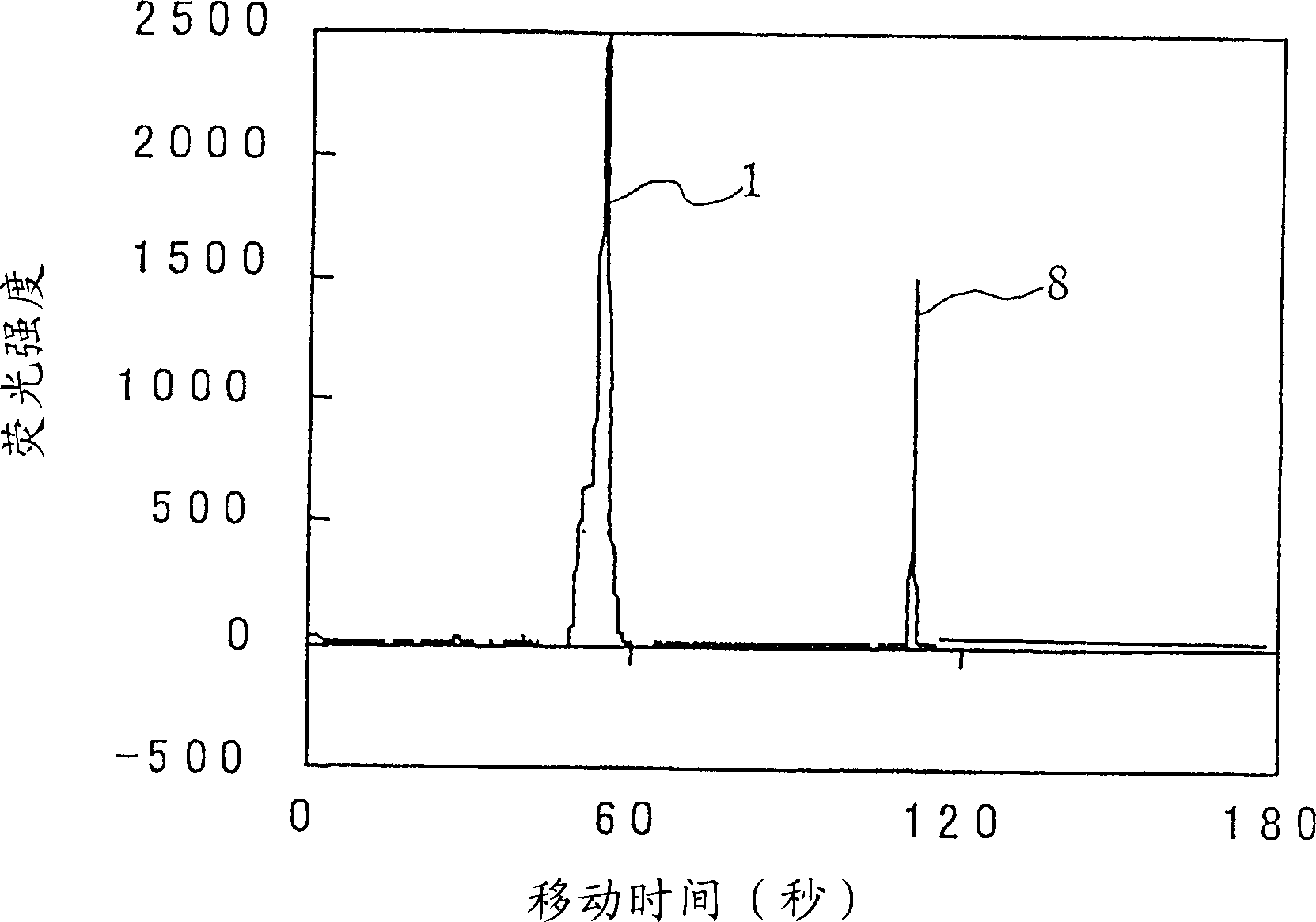

[0156] Example 2 (polymer micelles + PP method)

[0157] According to the PP method, the operation in Example 1 was carried out. Let the P intensity of the former be M, and the P intensity of the latter be L. As a result, two peaks were seen within the migration time of 180s. ( figure 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com