Parallel electromagnetic six-dimensional vibrating speed sensors

A vibration velocity, magnetoelectric technology, applied in the field of parallel magnetoelectric six-dimensional vibration velocity sensor, can solve the problems of poor extraction accuracy, difficult sensor, complex data analysis, etc., to achieve high output power, wide adaptability and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

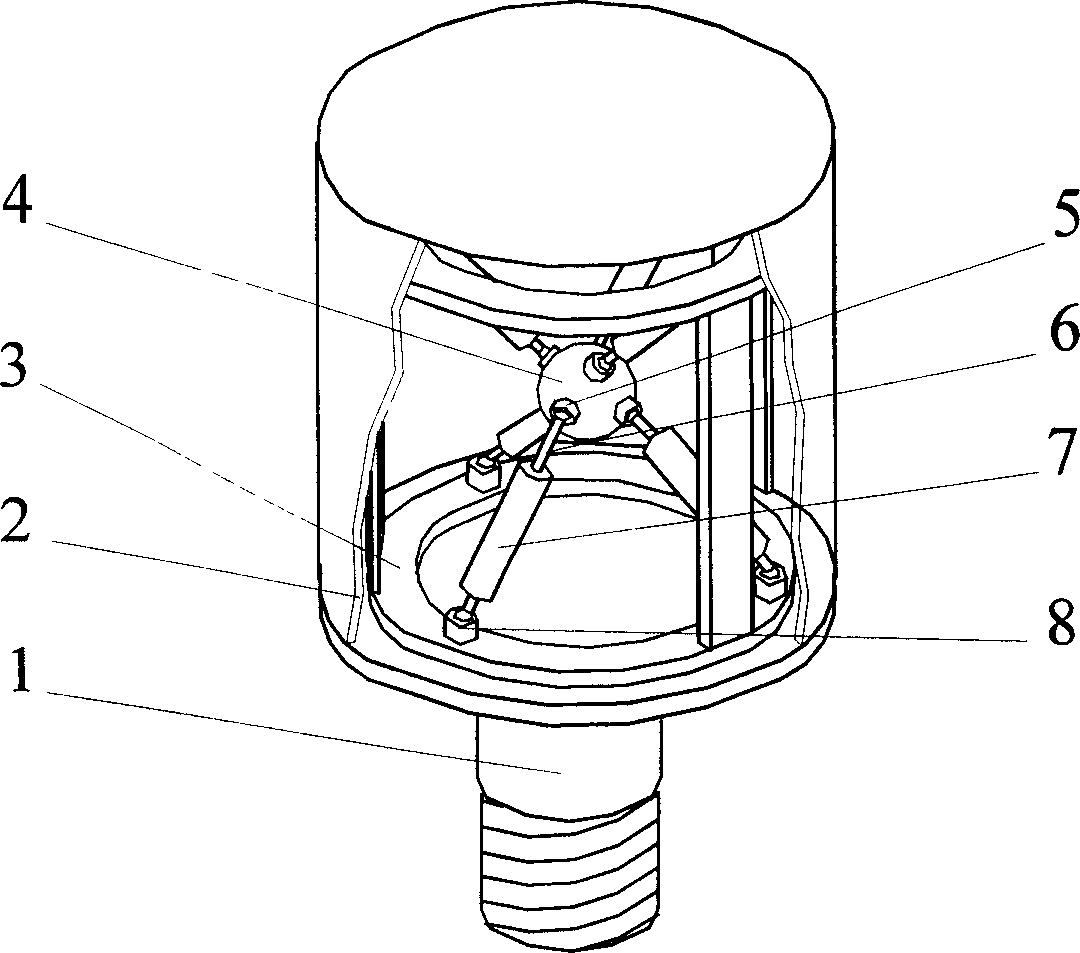

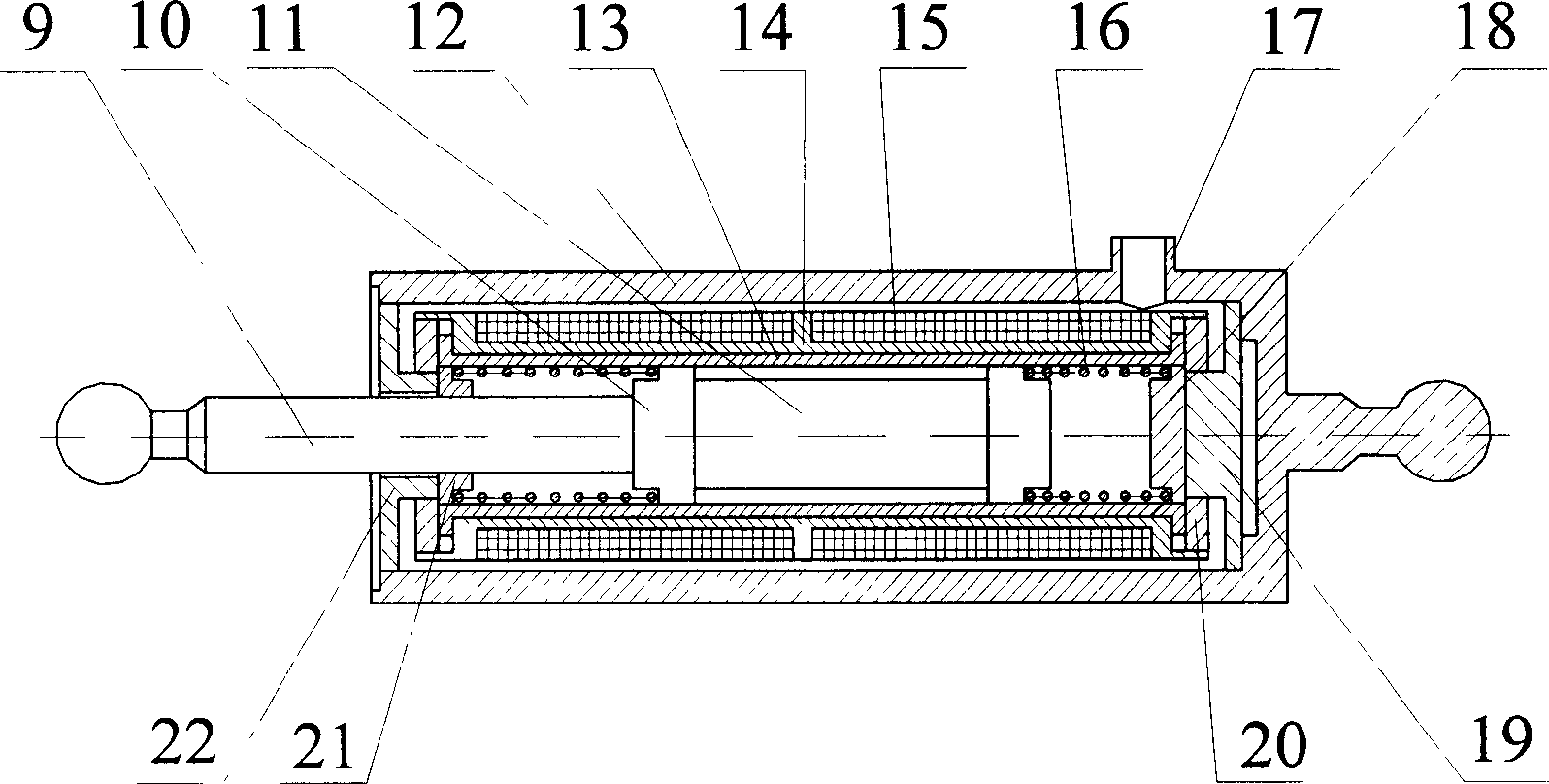

[0012] attached figure 1 is an embodiment of the present invention (see figure 1 ), the mount 1 is used to securely connect the sensor to the vibrating object, and the shell 2 is used to protect the internal components and shield the external magnetic field. The fixed frame 3 is a cage-shaped steel frame formed by connecting the upper and lower rings through three vertical plates. The ball joints 8 of the fixed frame are fixedly connected to the upper and lower rings respectively, and the lower ring is connected to the mounting seat 1 by screws. connected. The vibrating ball 4 consists of a steel shell with a lead metal core. The spherical hinge 5 and the fixed frame spherical hinge 8 are precision spherical hinges, and may also be flexible hinges. The structure of magnetic steel rod 6 and electromagnetic inductor 7 is shown in figure 2 . The magnetic steel rod 6 is rigidly connected into one by the connecting rod 9, the guide steel sleeve 10 and the permanent magnet 11;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com