Zonal water injection contanst flow packer

A technology of constant flow plugging and layered water injection, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., and can solve the problems of separate injection well commissioning and fishing, heavy testing workload, changes, increased deployment workload and Issues such as deployment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

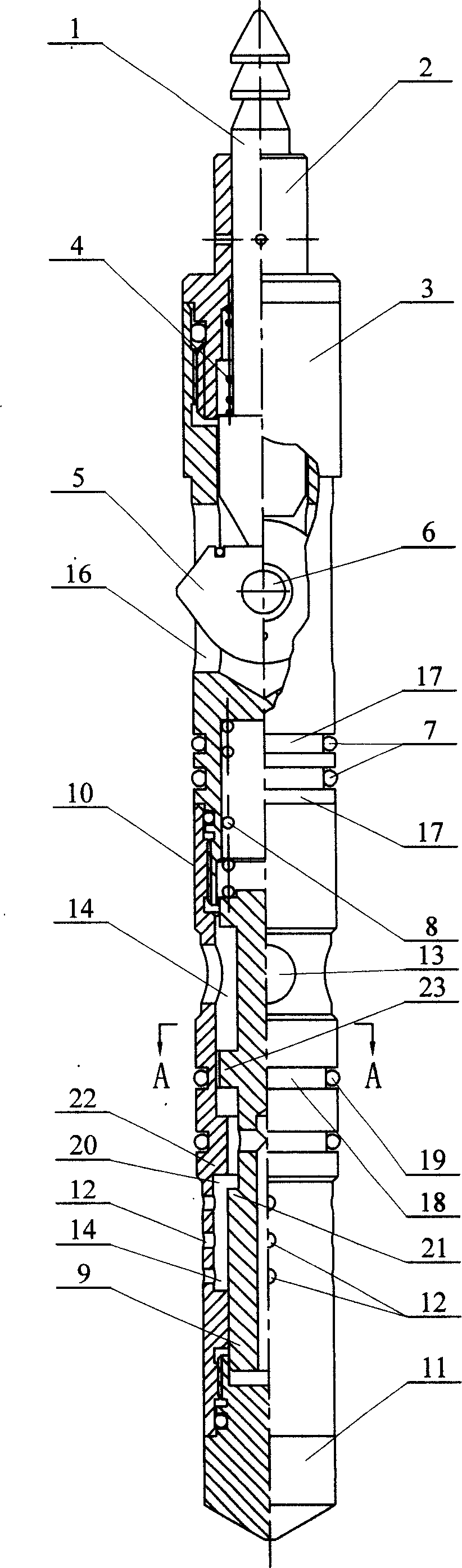

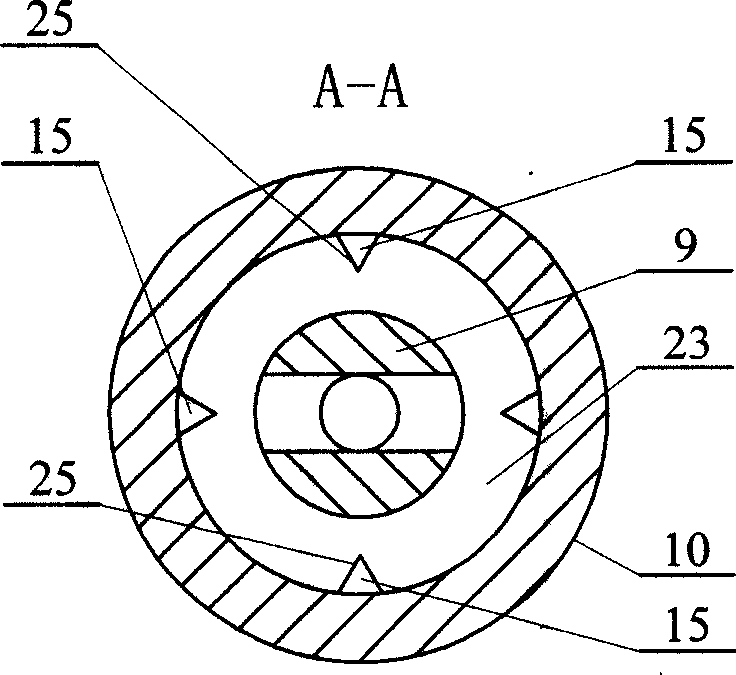

[0005] Specific implementation mode one: (see figure 1 , figure 2 ) This embodiment consists of a fishing rod 1, a pressure cap 2, a support seat 3, a spring 4, a cam 5, a small shaft 6, a first O-ring 7, a constant force spring 8, a sliding valve core 9, a valve sleeve 10, an inlet The pressure cap 11 and the second O-ring 19 are composed; the lower part of the fishing rod 1 is set in the pressure cap 2, the lower end of the pressure cap 2 is threadedly connected with the upper end of the support seat 3, and the lower part of the fishing rod 1 is connected with the lower end of the pressure cap 2. Spring 4 is arranged between, and small shaft 6 is located in support seat 3, and the inner end of cam 5 is arranged on the small shaft 6 in support seat 3, and the outer end of cam 5 is located at the opening groove 16 on support seat 3. Outside, the first O-ring seal 7 is arranged in the groove 17 of the lower part of the support seat 3, the lower end of the support seat 3 is th...

specific Embodiment approach 2

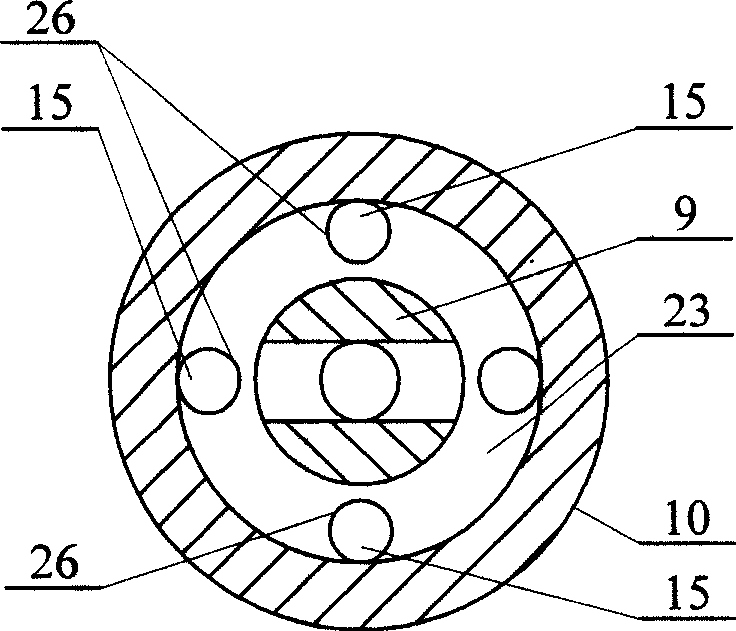

[0006] Specific implementation mode two: (see image 3 ) The difference between this embodiment and the first embodiment is that the section of the fixed orifice 15 is circular 26 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see Figure 4 ) The difference between this embodiment and the first embodiment is that the cross section of the fixed orifice 15 is a rectangle 27 . Other compositions and connections are the same as in the first embodiment.

[0008] Working principle: the present invention is equivalent to connecting the differential pressure reducing valve and the throttle valve in series and parallel to realize that when the water injection pressure difference fluctuates, the plug can also automatically adjust according to the pressure difference change and keep the water injection volume unchanged. Among them, the function of the fixed differential pressure reducing valve is to automatically change the flow area of its variable orifice 20 according to the water injection pressure difference through the sliding spool 9 and the constant force spring 8, and then change its own partial pressure, and provide a fixed pressure to the throttle valve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com