Electrothermic pipe overheat steam boiler

A technology of superheated steam and electric heating tubes, which is applied in the directions of steam superheating, steam generation, and the shape of heating elements, etc. It can solve the problems of superheated steam limitations and inconvenient assembly and maintenance, and achieve small footprint, simple manufacture, and broaden applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

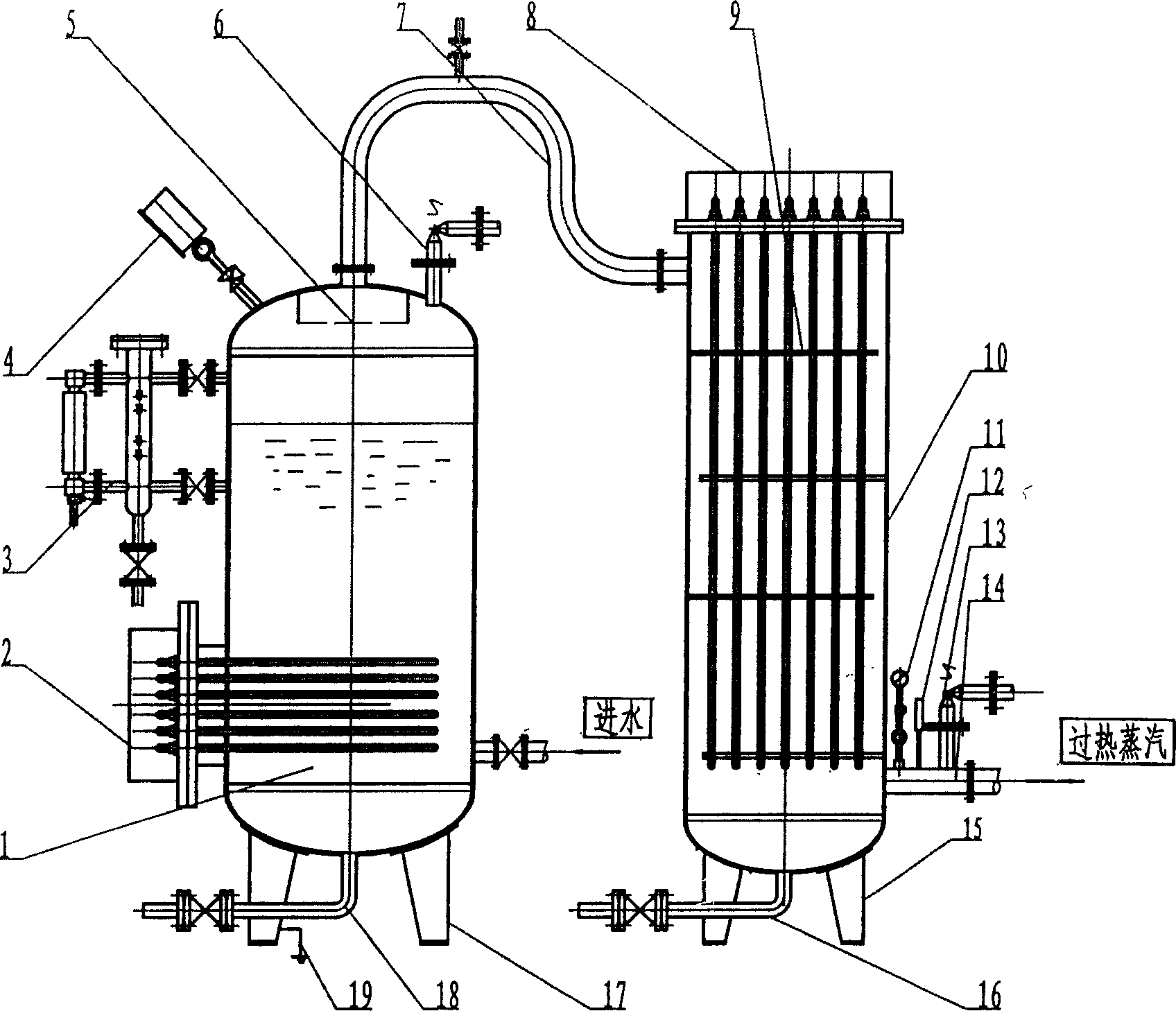

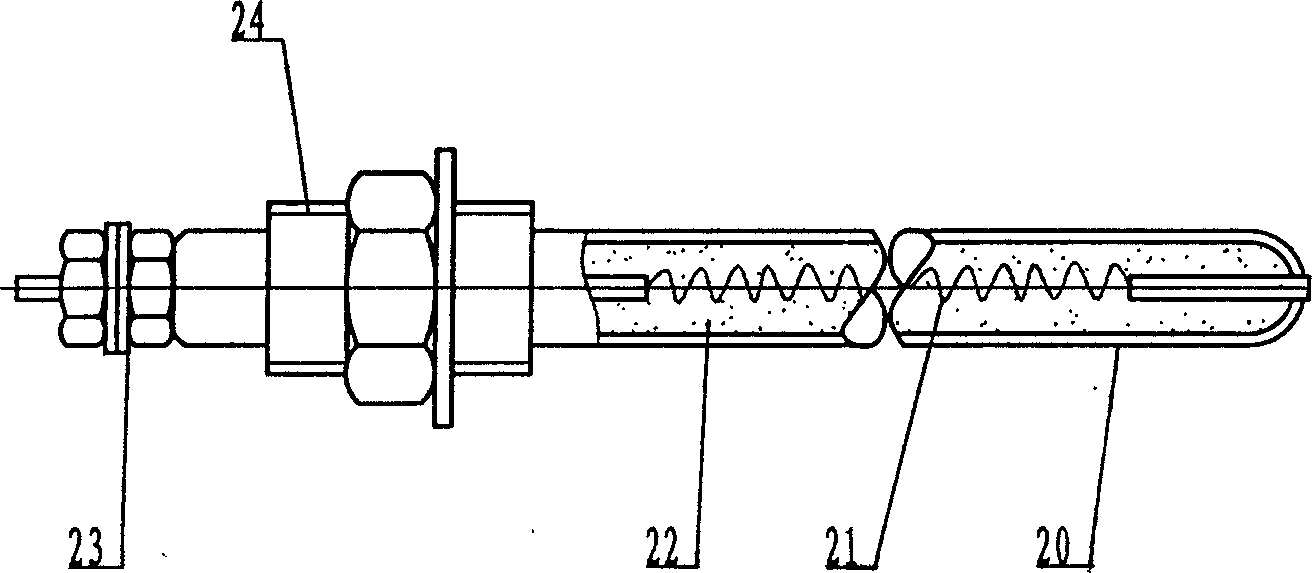

[0025] Embodiment 1: structure such as figure 1 with figure 2 As shown, among them, figure 1 It shows that the evaporation capacity is 1T / H, and the working pressure is 8Kgf / cm 2 , a schematic diagram of an electric heating superheated steam boiler with a superheated steam temperature of 450 ° C, vertical layout. The boiler is divided into two parts, including the boiler body 1 that generates saturated steam and the superheater 10 that generates superheated steam. The electric heating tubes 2 and 8 in the boiler body 1 and the superheater 10 are all single-ended single-outlet electric heating tubes, which adopt Y-shaped connection , the shell of the electric heating tube 20 and the shell of the boiler body 1 and the superheater 10 serve as neutral points and are reliably grounded. Boiler body 1 has a cylinder diameter of 900 mm and a wall thickness of 10 mm; its two ends are welded with elliptical heads. The boiler body 1 is arranged in a vertical structure, its lower par...

Embodiment 2

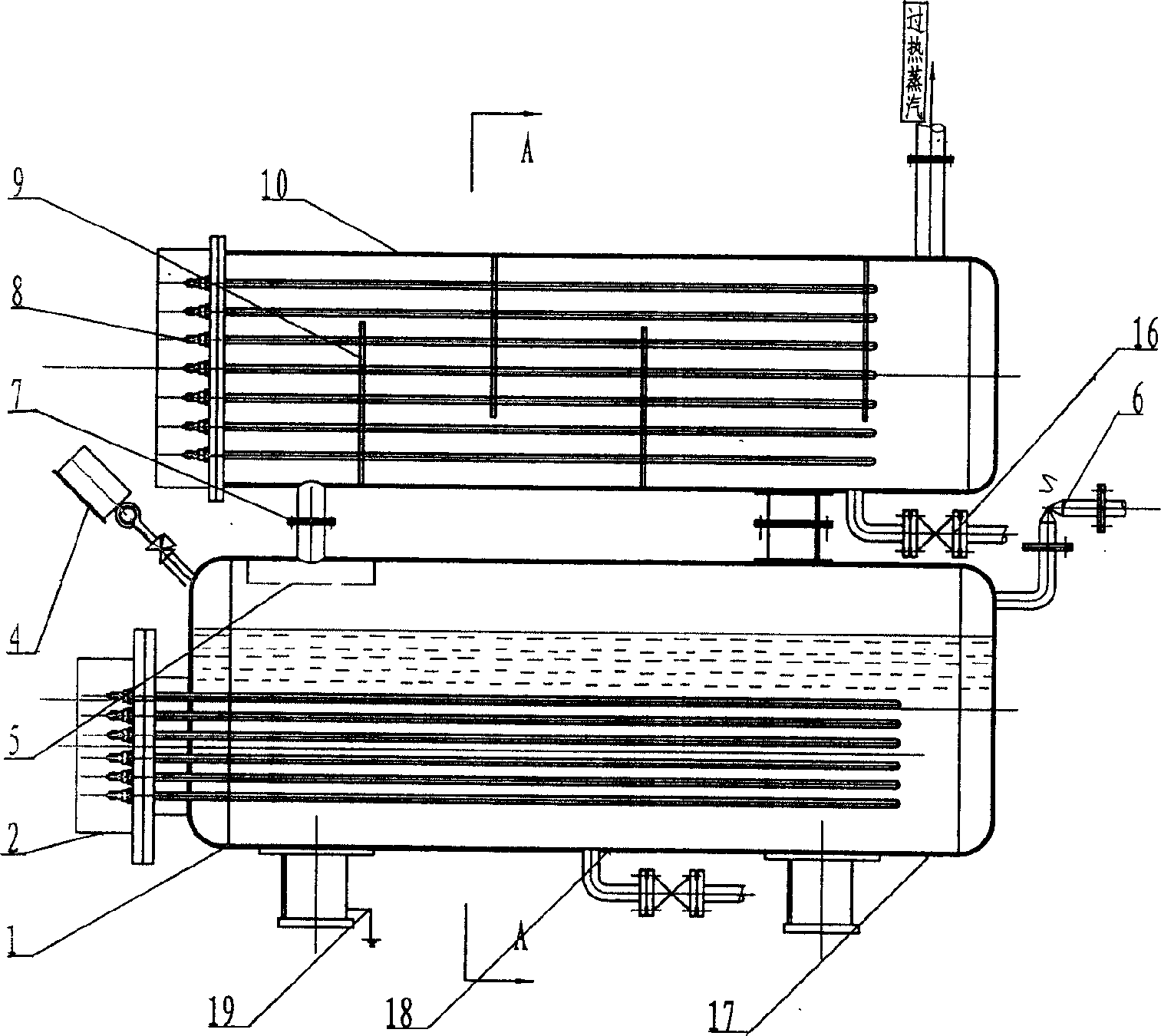

[0027] Embodiment 2: as image 3 with Figure 4 As shown, the boiler body and superheater are arranged horizontally. Wherein, both ends of the cylinder body of the boiler body 1 are welded with flat-shaped heads. The lower part of the boiler body 1 is a water space, and the upper part is a steam space. 90 single-ended single-outlet electric heating tubes 2 with a thermal power of 8.5KW are connected to the flat head at one end of the body 1 through threads, and the electric heating tubes are arranged horizontally. The superheater 10 has a diameter of 700mm and a wall thickness of 8mm. One end of the superheater is welded with a flat head, and the other end is welded with a flange and is sealed by connecting the tube sheet with the flange. 96 single-end single-outlet electric heating tubes 8 with a diameter of 20mm, a length of 2000mm, and a thermal power of 3KW are inserted into the superheater 10 through the screw holes of the upper tube plate of the superheater and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com