Electric spark machining liquid storage case device for treatment fluid containing addition agent

An additive, electric spark technology, applied in the field of processing and circulation devices, storage, can solve the problem of low working life of the working fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

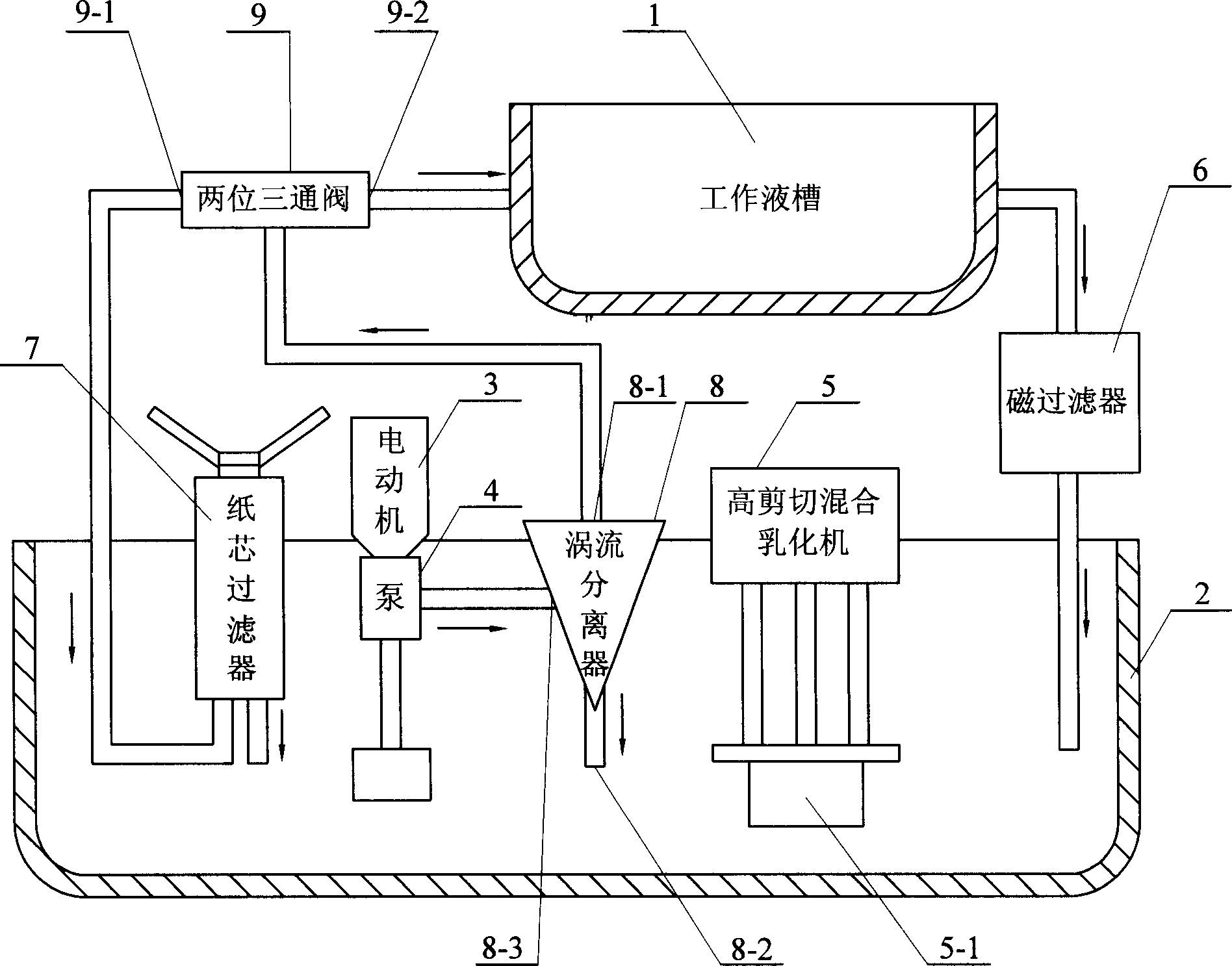

[0005] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. It consists of a working liquid tank 1, a liquid storage tank 2, a vortex separator assembly, a high-shear mixing emulsifier 5, a magnetic filter 6, a two-position three-way valve 9, and a paper core filter 7. The eddy current separator assembly consists of a pump 4. Composed of motor 3 and eddy current separator 8, the liquid inlet of magnetic filter 6 is connected to the liquid outlet of working fluid tank 1, and the liquid outlet of magnetic filter 6 is connected to liquid storage tank 2, high shear mixing and emulsification The stirring blade 5-1 of the machine 5 extends into the liquid storage tank 2, the motor 3 provides power to the pump 4, the inlet of the pump 4 extends into the liquid storage tank 2, and the outlet of the pump 4 communicates with the inlet 8 of the vortex separator 8 -3, the lower outlet 8-2 of the vortex separator 8 extends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com