Rotor of hydraulic pulper

A hydraulic pulper and rotor technology, which is applied in the field of papermaking machinery, can solve the problems of bulky size, large installation area, and heavy weight, and achieve the effects of improving dissociation efficiency, benefiting circulation, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

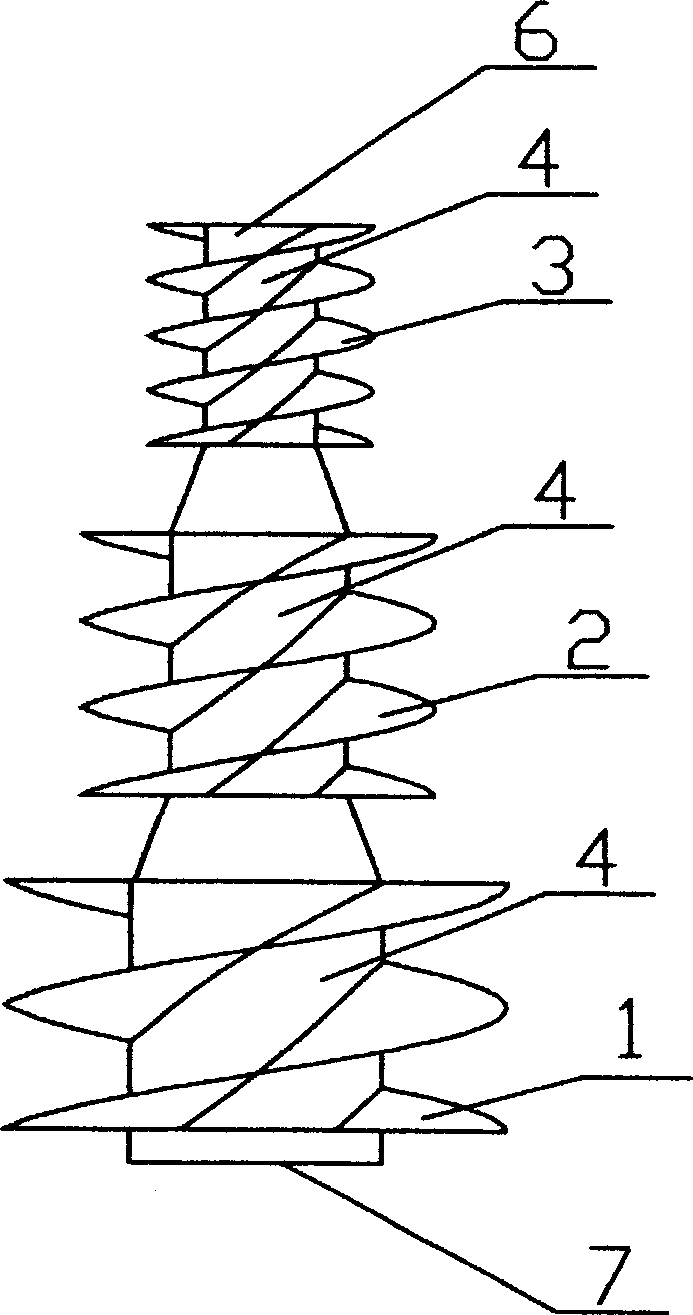

[0013] Embodiment one: if figure 1 As shown, a hydropulper rotor includes a rotor central shaft 4, screw blades 1, 2, and 3 fixed on the central shaft 4, the rotor central shaft 4 is a stepped shaft, free from the central shaft 4 The shaft diameters of the stepped shafts from the end 6 to the driving end 7 increase sequentially, the shaft sections of the stepped shafts with different shaft diameters transition smoothly through conical surfaces, and the shaft sections of the stepped shafts with different shaft diameters are respectively provided with spiral The blades 1, 2, 3, the pitches between the helical blades 1, 2, 3 respectively provided on the shaft sections with different shaft diameters are different.

[0014] The outer edges of the helical blades 1, 2, and 3 respectively provided on the shaft sections with different shaft diameters are distributed in a cylindrical surface. This distribution can be that the edges of the helical blades 1, 2, and 3 are distributed in a...

Embodiment 2

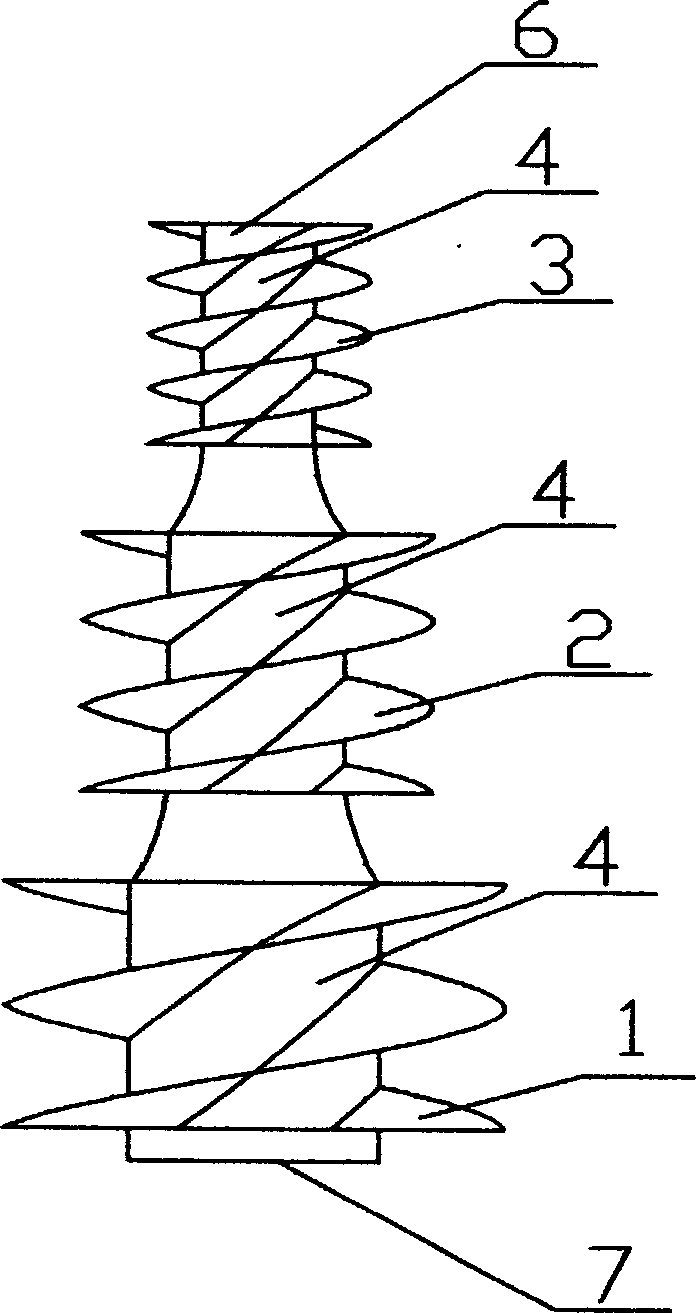

[0016] Embodiment 2: The structural form is basically the same as that of Embodiment 1, except that the shaft sections of the stepped shafts with different shaft diameters transition smoothly through the streamline surface, so that the circulation of the slurry is smooth and unimpeded.

Embodiment 3

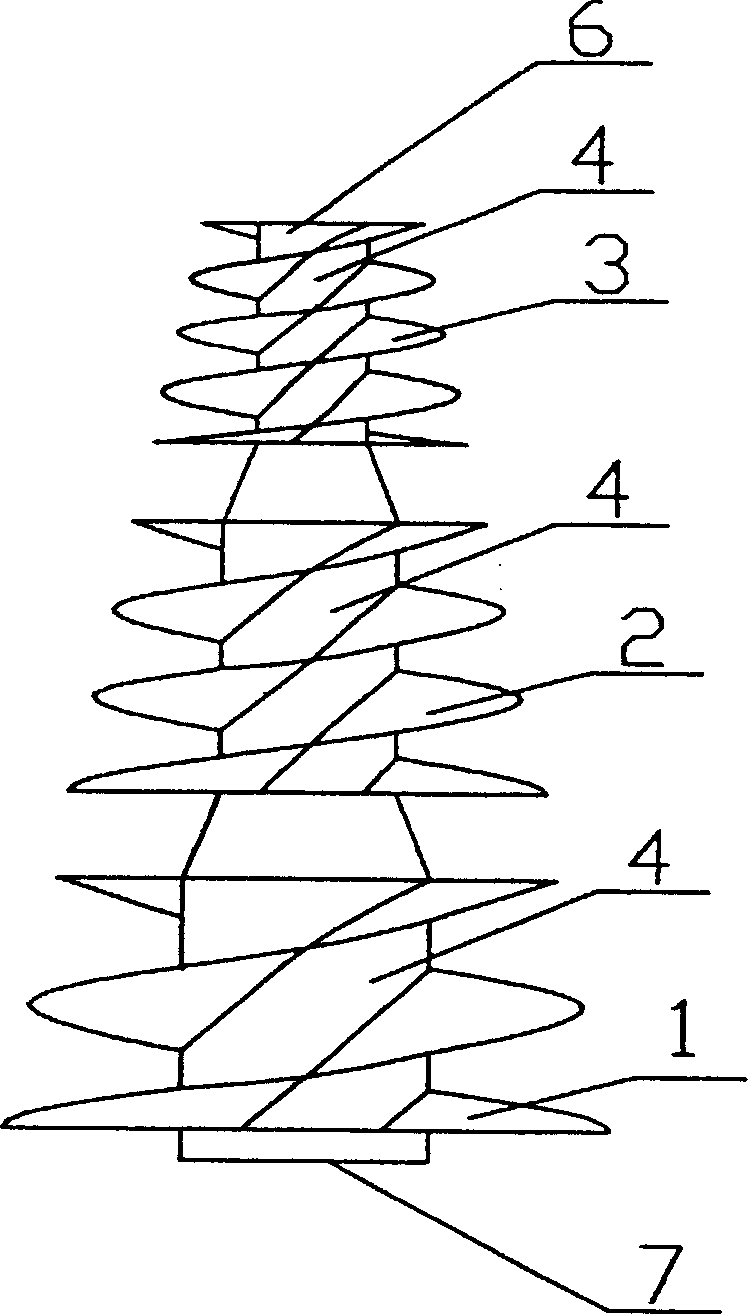

[0017] Embodiment 3: The structural form is basically the same as Embodiment 1 and Embodiment 2, the difference is that the outer edges of the spiral blades 1, 2, 3 respectively provided on the shaft sections with different shaft diameters are distributed in the In a conical surface, the distribution may be that the edges of the helical blades 1, 2, and 3 are distributed in a common conical surface, and the edges of the helical blades 1, 2, and 3 may also be distributed in their respective conical surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com