Method for deprivig sulfur dioxide in solution of citrate

A technology of sulfur dioxide and citrate, which is applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve problems affecting the circulation and absorption of citrate solution, high decomposition rate of citrate, and high steam loss , to achieve the effects of reducing loss, reducing production, and reducing energy for separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

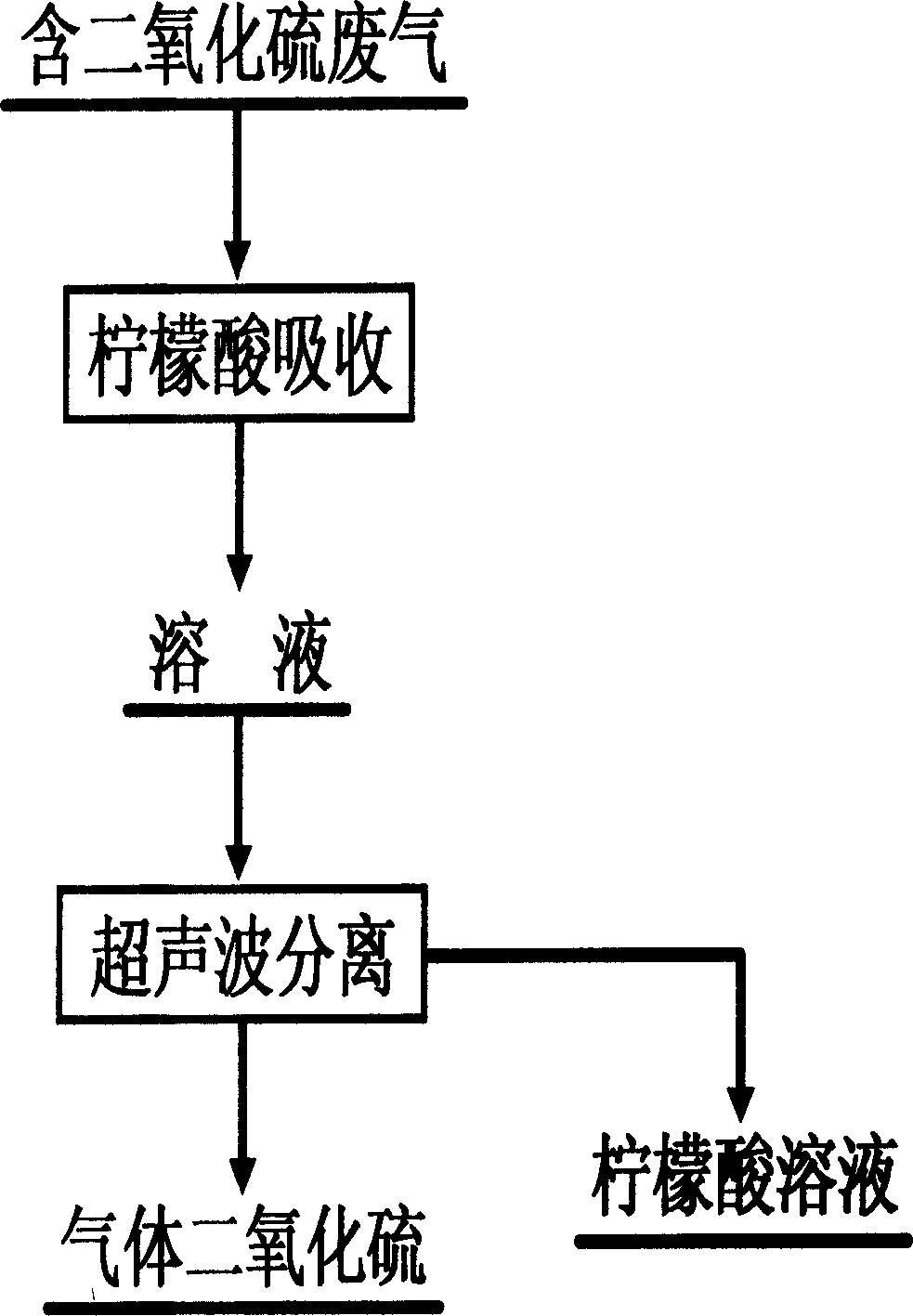

[0018] Such as figure 1 As shown, the operation steps of ultrasonic separation of sulfur dioxide are as follows:

[0019] (1) In the packing reaction tower, under the condition of temperature 30 DEG C, the exhaust gas with a sulfur dioxide concentration of 1.5% reacts with a 1.5mol / L citrate solution with a pH value of 4.5 to obtain a citrate solution containing sulfur dioxide; in the solution The concentration of sulfur dioxide is 160g / L; the pH of the solution is 1.50.

[0020] (2) Put the solution into an ultrasonic reactor, and react for 1.5 hours under the action of ultrasonic waves with a frequency of 20KHz, a solution temperature of 60°C, and a power of 60W / L to decompose 90% of sulfurous acid and escape from the solution in the form of sulfur dioxide ; After conventional treatment, the remaining solution is used to circulate and absorb sulfur dioxide-containing waste gas.

Embodiment 2

[0022] Absorption process is identical with example 1, and solution composition is substantially identical with example 1. Put the solution into the ultrasonic reactor, the temperature of the solution is 60°C, under the action of ultrasonic waves with a frequency of 40KHz and a power of 65W / L, react for 1.5 hours to decompose 96.3% of sulfurous acid and escape the solution in the form of sulfur dioxide; the remaining solution After conventional treatment, it is used to circulate and absorb sulfur dioxide-containing waste gas.

Embodiment 3

[0024] Absorption process is identical with example 1, and solution composition is substantially identical with example 1. Put the solution into the ultrasonic reactor, the temperature of the solution is 60°C, under the action of ultrasonic waves with a frequency of 60KHz and a power of 70W / L, react for 1.5 hours to decompose 98.2% of sulfurous acid and escape the solution in the form of sulfur dioxide; the remaining solution After conventional treatment, it is used to circulate and absorb sulfur dioxide-containing waste gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com