Three-layered automatic test system for safety regulations in master slaver mode

An automatic test system and a fully automatic test technology, applied in the transmission system, signal transmission system, electrical signal transmission system, etc., can solve the problems of test function expansion and poor flexibility, singleness, and inability to test multiple electronic products at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

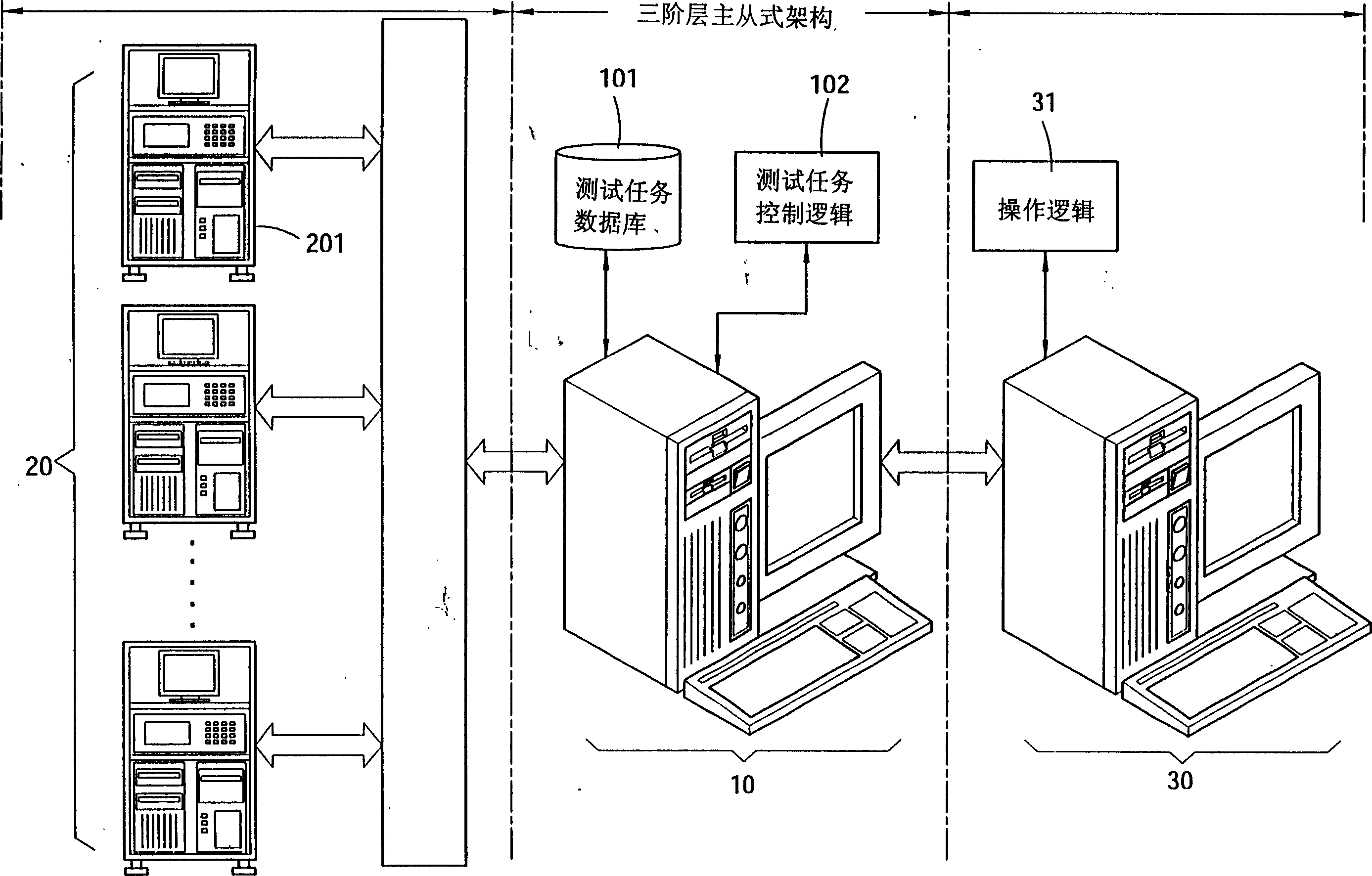

[0021] The preferred embodiment of the present invention can be realized through the three-level master-slave system architecture shown in Figure 1. This three-level master-slave safety automatic test system includes:

[0022] The server 10 is located in the middle layer of the three-tier architecture, and a preferred embodiment can be realized by a computer with a server function.

[0023] This server 10 has built-in test task database 101, and described test task database 101 stores and comprises: test setting file, instrument setting file, test result, task scheduling and other data; the control logic (control logic) of test task ) 102, the control logic 102 referred to here refers to the operation program (operational and procedure) for issuing test task instructions to the fully automatic test machine 201 to perform the test task, and the control logic 102 can be through software or hardware be realized;

[0024] The fully automatic test working machine group 20 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com