Method and tabbing station for fitting tabs to a solar cell, and method and apparatus for manufacturing a solar panel

A technology of solar cells and connecting sheets, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to establish connections, damage to solar cells, and indefinitely limited time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

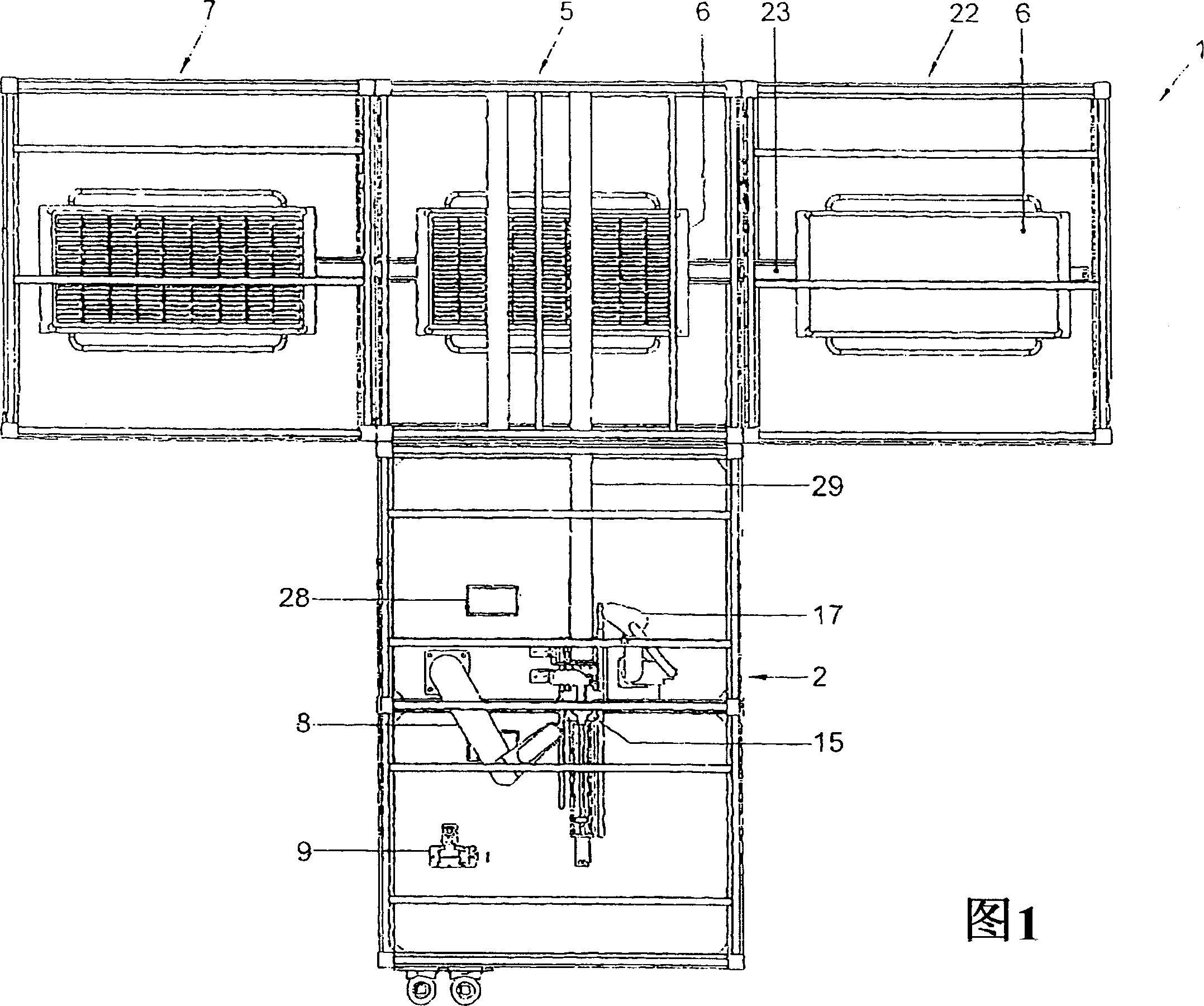

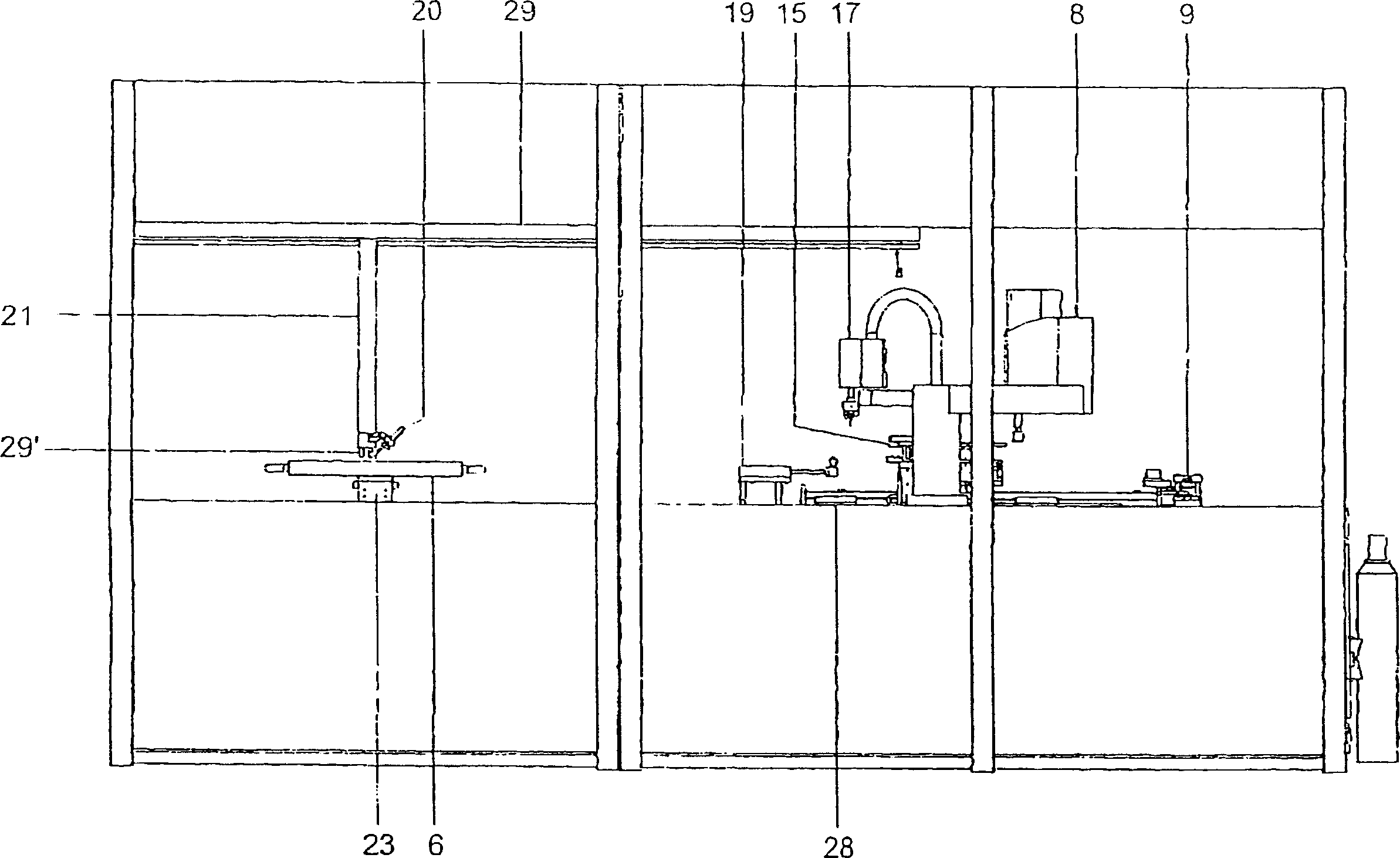

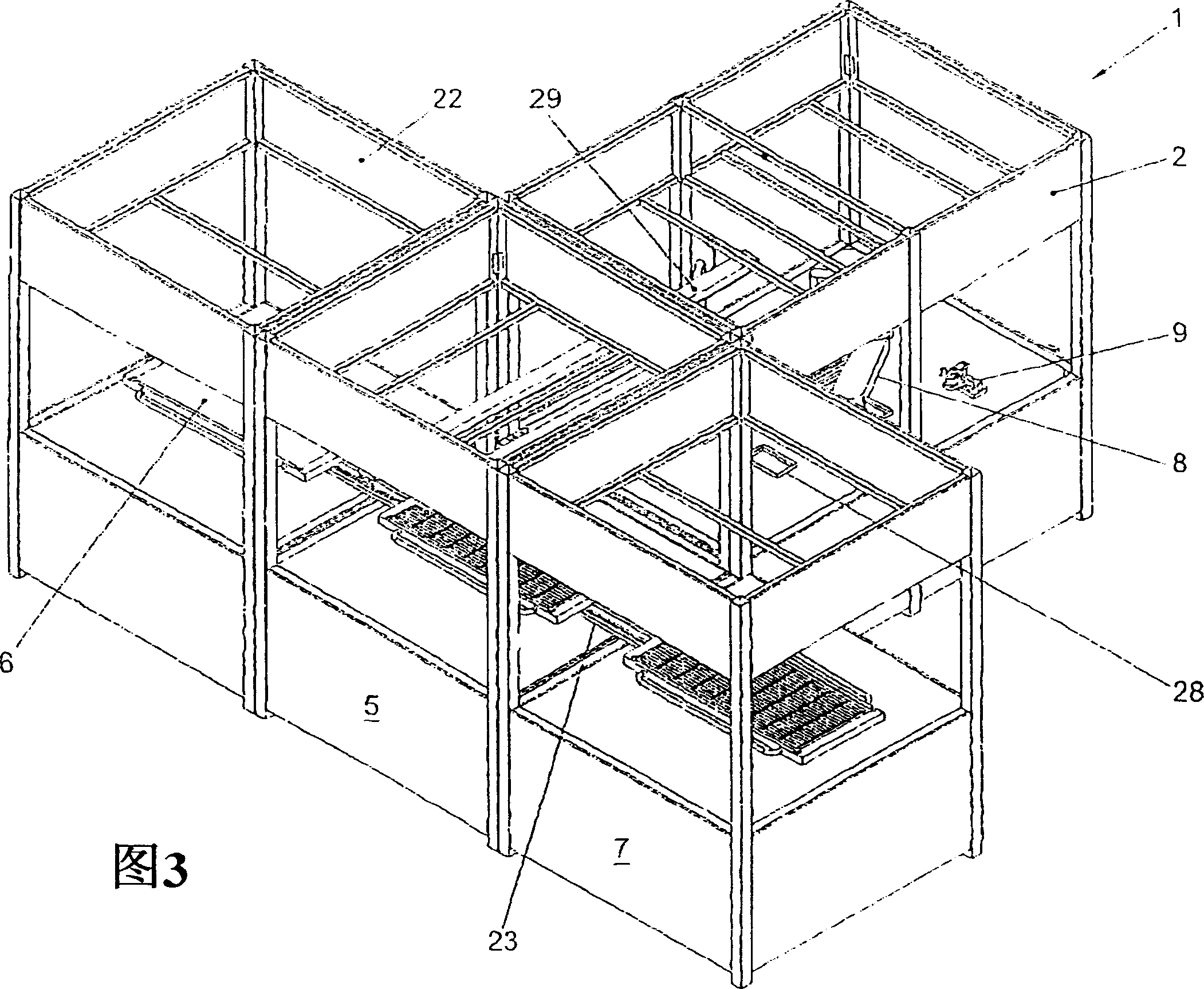

[0022] The apparatus 1 shown in top plan view in Fig. 1 is used to manufacture solar panels in a flexible manner. Thus, the device has a lug fixing station 2 in which lugs 4 (pieces) are fitted to solar cells 3 Figure 4 to Figure 7). The device also has a stringing station 5 in which the solar cells 3 , which have been fitted with webs 4 in the web fixing station 2 , are arranged adjacent to each other on a translucent plate 6 and there Appropriately selected tabs 4 of solar cells are connected to each other. In the lamination station 7 the translucent sheet 6 on which the solar cells 3 are interconnected in the stringing station 5 is fitted with at least one coating in order to cover said solar cells. Said panels 6 are fed into a pre-assembly station 22 on which solar cells 3 equipped with tabs 4 will be arranged later in a stringing station 5 . In the pre-assembly station 22 the dimensions of the plate 6 can eg be determined and a release coating applied to the plate. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com