Method for producing saccharin sodium

A production method and technology of sodium saccharin, applied in the field of food additive production, can solve the problems of polluted air, high labor intensity, fast heating, etc., and achieve the effects of stable reaction process, improved working environment, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for producing sodium saccharin, comprising the reaction steps of amidation, Hofmann degradation, lipidation, diazotization, replacement, chlorination, ammoniation, acid precipitation, alkalization, and decolorization, followed by filtration, concentration, crystallization, and drying to get the finished product. The production method of sodium saccharin mainly improves the preparation steps of acid analysis and alkalization reaction, and obtains an intermediate ammoniated solution from the ammoniation reaction as the main component of the acid analysis and alkalization reaction;

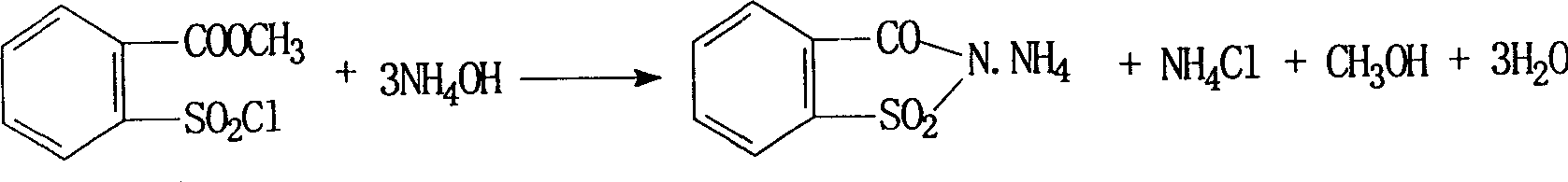

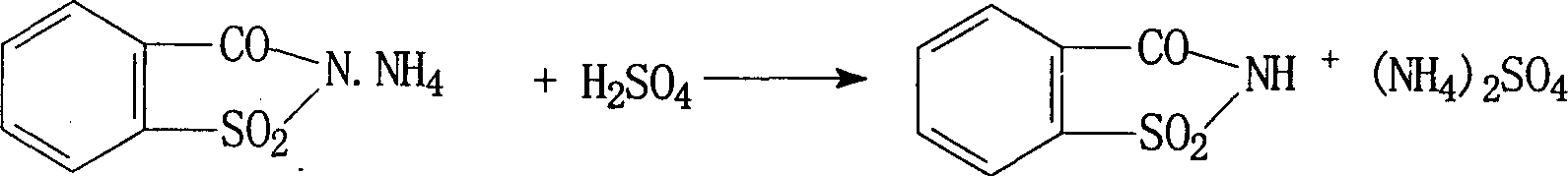

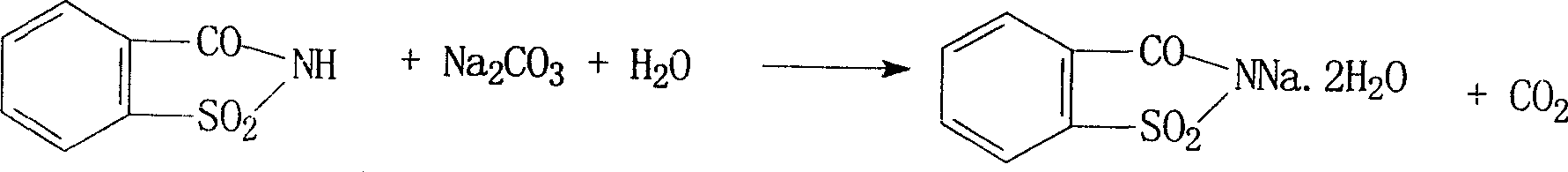

[0019] The ammoniation reaction formula is:

[0020]

[0021] Acid analysis, alkalization reaction steps are as follows:

[0022] (1) The ammoniated solution and the toluene washing water prepared after the ammoniation reaction are pumped into the acid analysis and alkalization reaction kettle and fully stirred evenly;

[0023] (2) Add water to adjust the concentration of ammonia...

Embodiment 2

[0037] Acid analysis, alkalization reaction steps are as follows:

[0038] (1) The ammoniated solution and the toluene washing water prepared after the ammoniation reaction are pumped into the acid analysis and alkalization reaction kettle and fully stirred evenly;

[0039] (2) Add water to adjust the concentration of ammoniated solution and toluene washing solution to 1.05~1.06kg / m 3 , measure the volume of the ammoniated solution, the ammoniated solution is 1500L according to the ratio, add 375L of toluene and continue to stir, the temperature is 18°C-20°C;

[0040] (3) Add 375L of sulfuric acid with a concentration of 15% in the stirring, the time is 10-15 minutes, the temperature is below 15-30°C, the measured pH is between 1-4, and the insoluble colloidal particles are precipitated under sufficient stirring, and the insoluble particles are observed. The surface of the colloidal particles should be smooth and about the size of red bean grains; the end point of acid precip...

Embodiment 3

[0050] Acid analysis, alkalization reaction steps are as follows:

[0051] (1) The ammoniated solution and the toluene washing water prepared after the ammoniation reaction are pumped into the acid analysis and alkalization reactor and fully stirred evenly;

[0052] (2) Add water to adjust the concentration of ammoniated solution and toluene washing solution to 1.05~1.06kg / m 3 , measure the volume of the ammoniated solution, the ammoniated solution is 1700L according to the ratio, add 425L of toluene and continue to stir, the temperature is 18°C-20°C;

[0053](3) Add 425 L of sulfuric acid with a concentration of 30% in the stirring, the time is 10-15 minutes, the temperature is 15-30 ° C, the measured pH is between 1 and 4, the insoluble colloidal particles are precipitated under sufficient stirring, and the insoluble colloids are observed. The grain surface should be smooth and about the size of a red bean grain; the end point of acid precipitation should be clarified by ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com