Movable dwellings

A technology for prefabricated houses and panels, which is applied in the directions of structural elements, building components, and elongated structural components for load-bearing, etc., can solve the problems that the columns, beams, and connecting structures of prefabricated houses cannot meet the requirements of prefabricated houses. To achieve the effect of excellent sound insulation, low price, and purification of the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As shown in Figure 10, the mobile house includes a board 1, a beam column 3 and a door 5, and the board 1, the beam column 3 and the door 5 all adopt a felt made of waste textile fibers and at least one layer of durable fabric on its outer surface. The panels made of alkali glass fiber grid cloth impregnated with cement slurry and the intermediate layer between the panels are composed. The mobile house is assembled and combined by the above-mentioned boards 1, beams and columns 3 and doors 5.

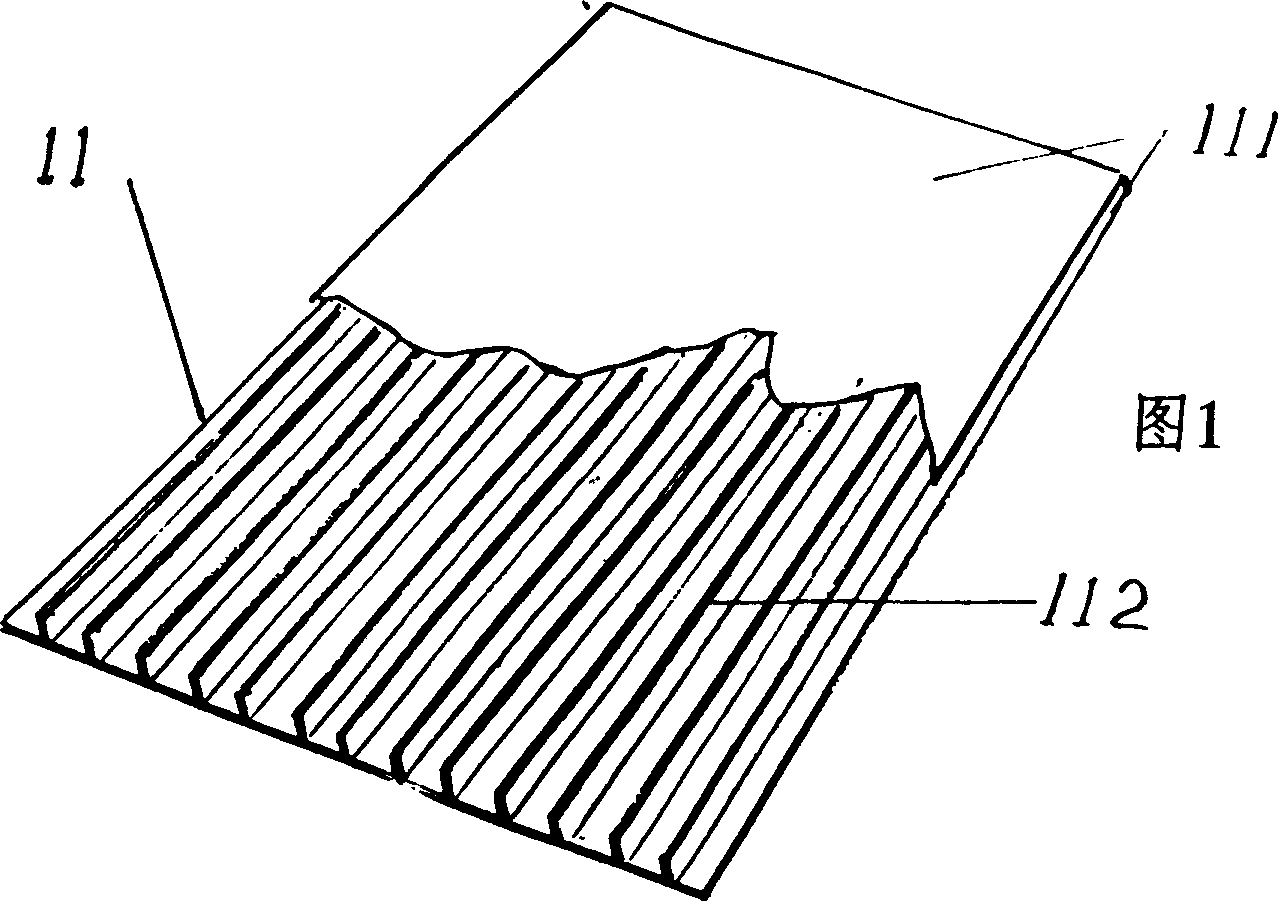

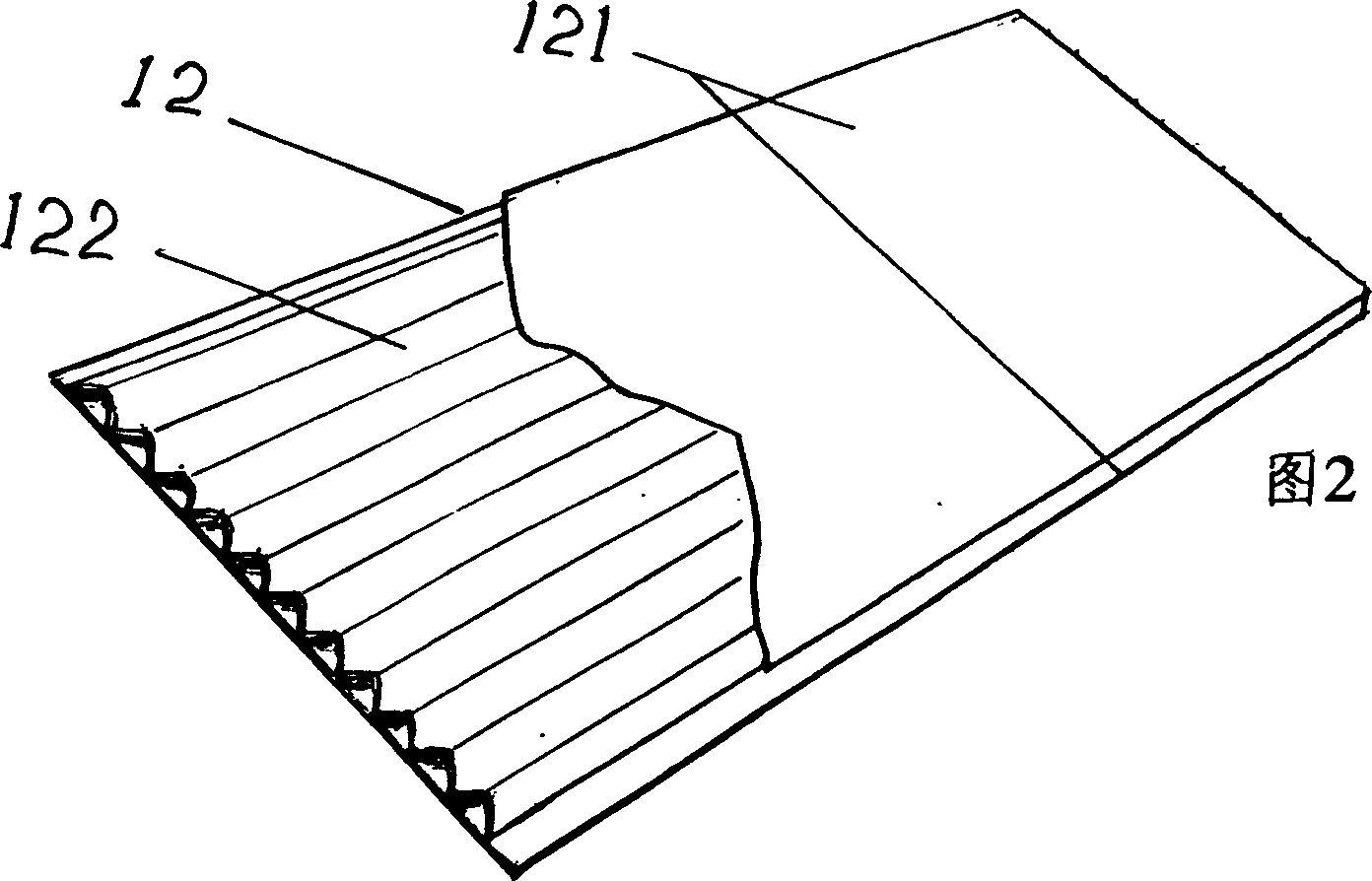

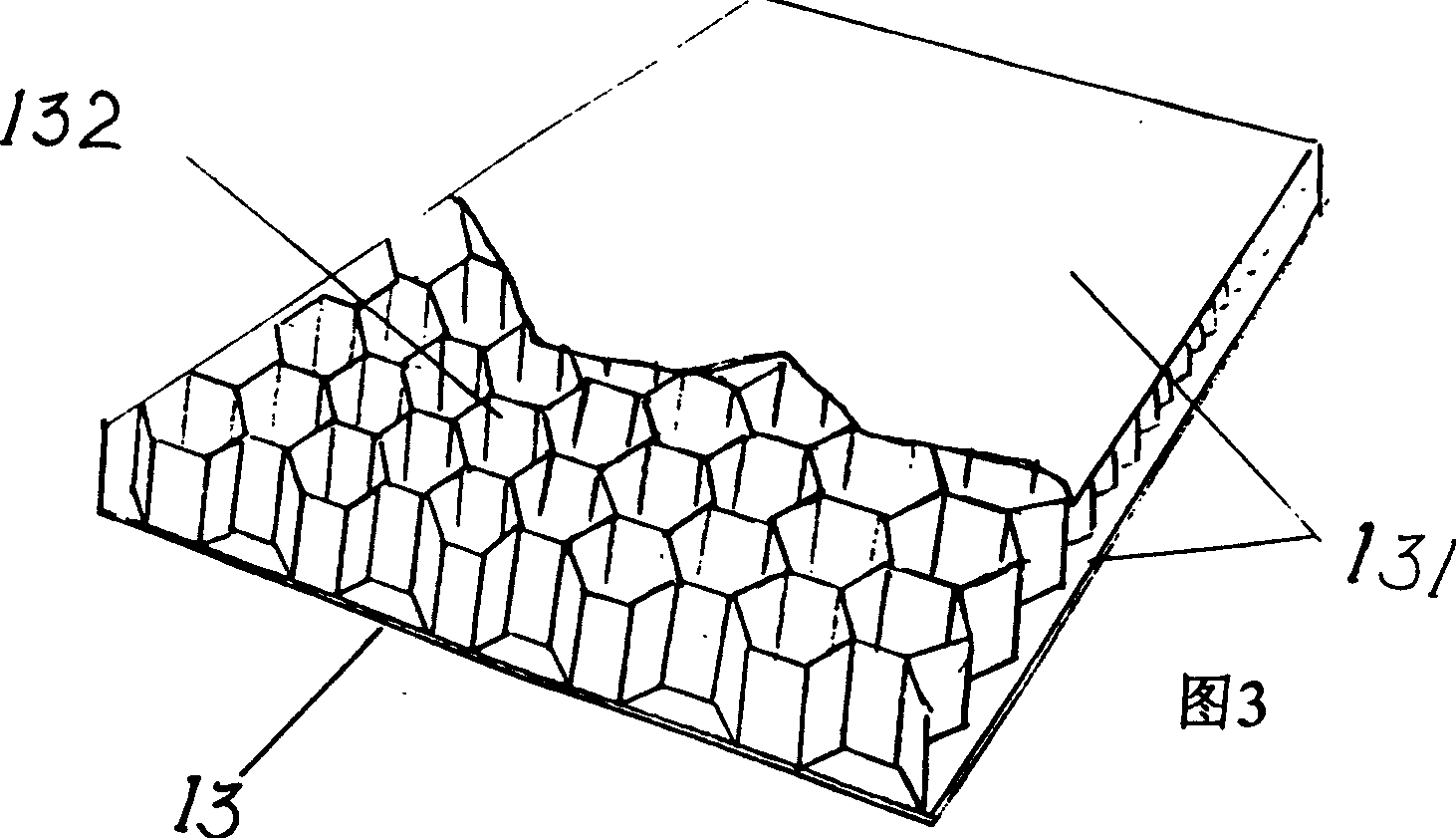

[0033] As shown in Figure 1, Figure 2, and Figure 3, the board 1 refers to a board that is used as a roof panel, wall board, floor, floor slab, partition, door leaf, etc. Panels for decorative panels or furniture panels1. The middle layer refers to the thermal insulation layer between the two panels of the panel 1; the panel refers to the upper and lower panels of each panel 1. The board 1 refers to the lining strip board 11 , corrugated board 12 or honeycomb board 13 that are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com