Apparatus and method for heating work pieces

A technology of heating device and heating method, applied in induction heating device, electric furnace heating, induction heating and other directions, can solve problems such as heating temperature difference and limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

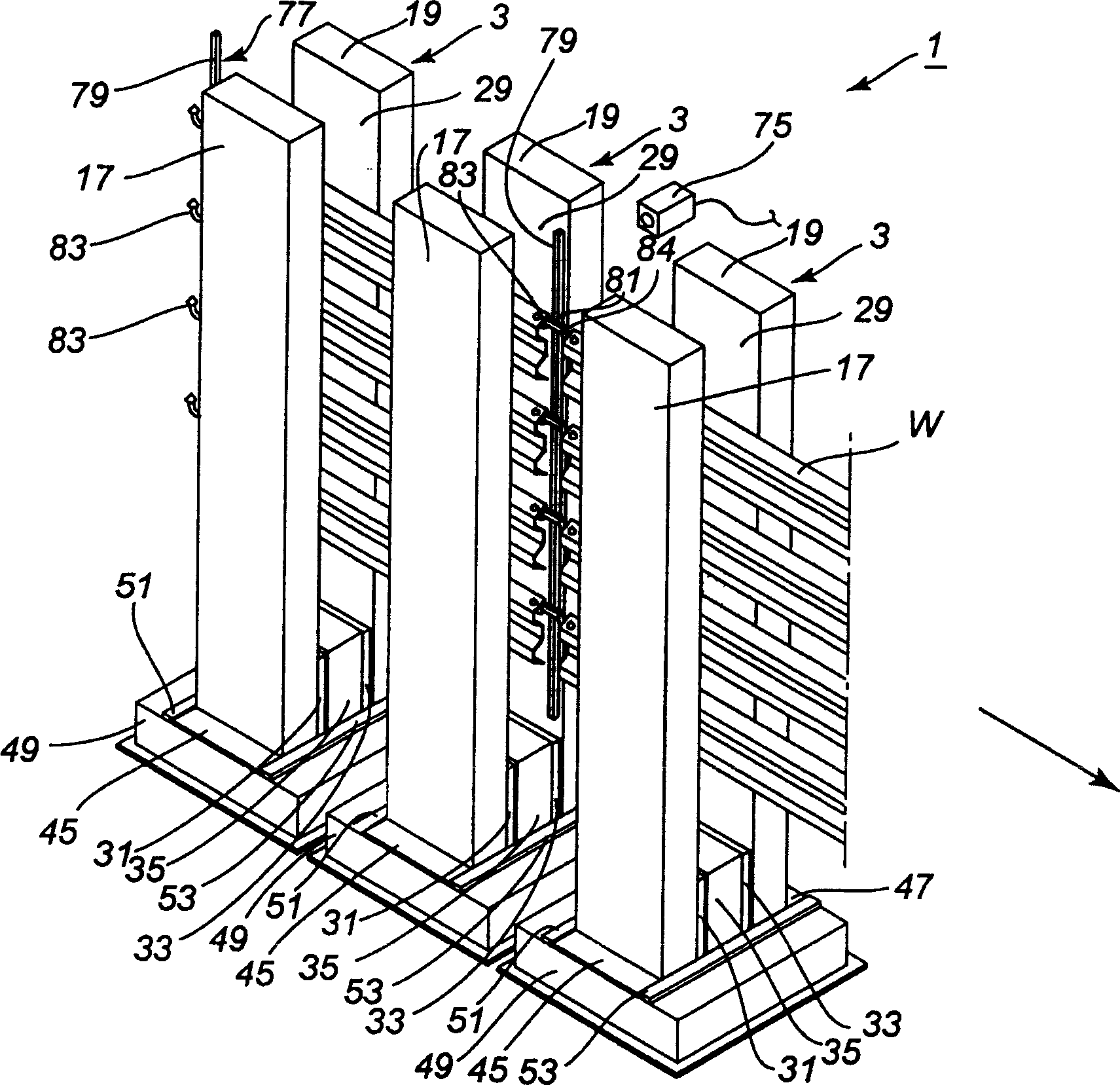

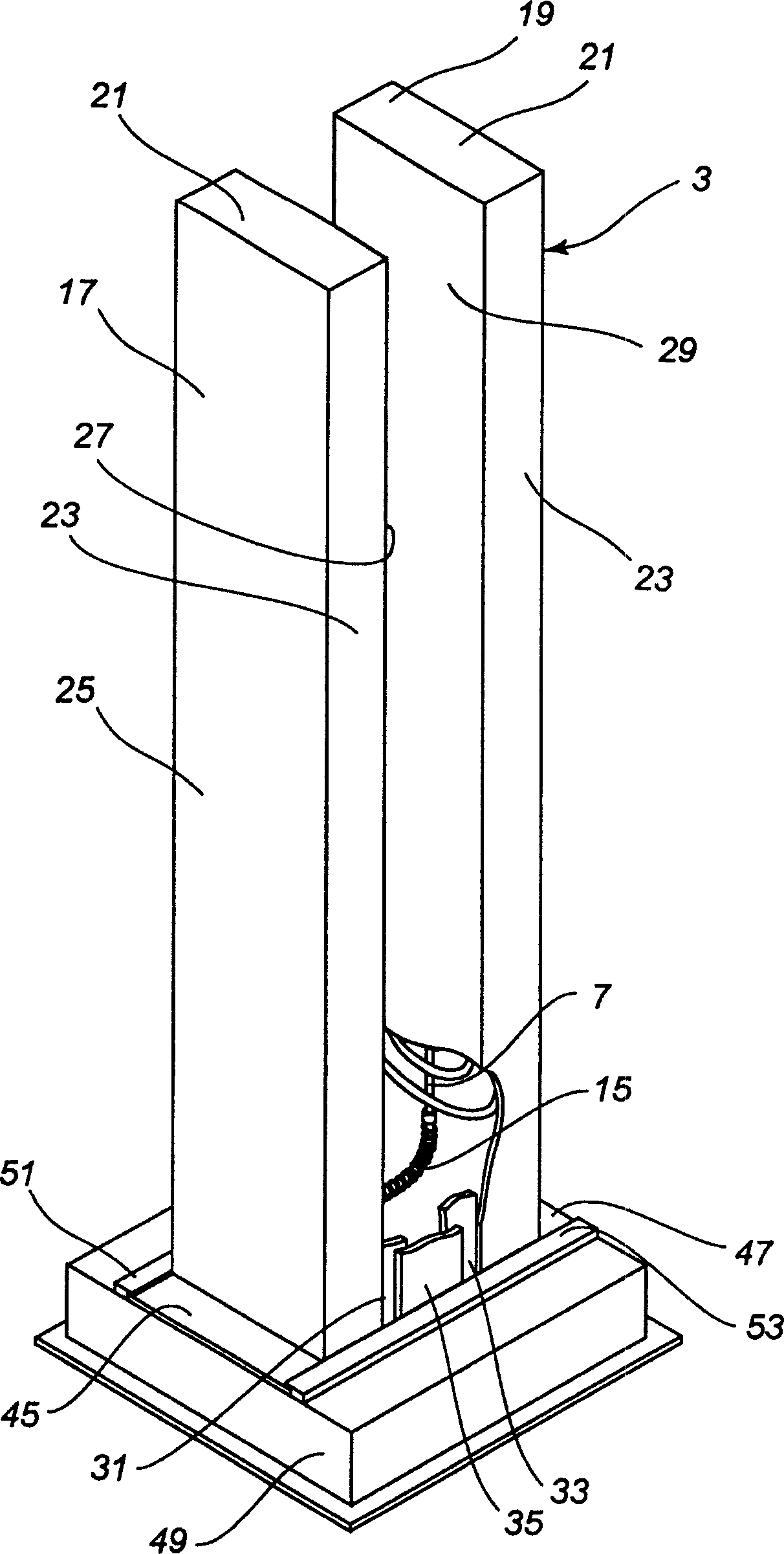

[0067] The following is based on Figure 1 to Figure 12 , the workpiece heating device 1 according to the first embodiment of the present invention will be described.

[0068] Reference numeral 3 denotes a high-frequency induction heating unit including a pair of workpiece coils 5 and 7 provided to face each other.

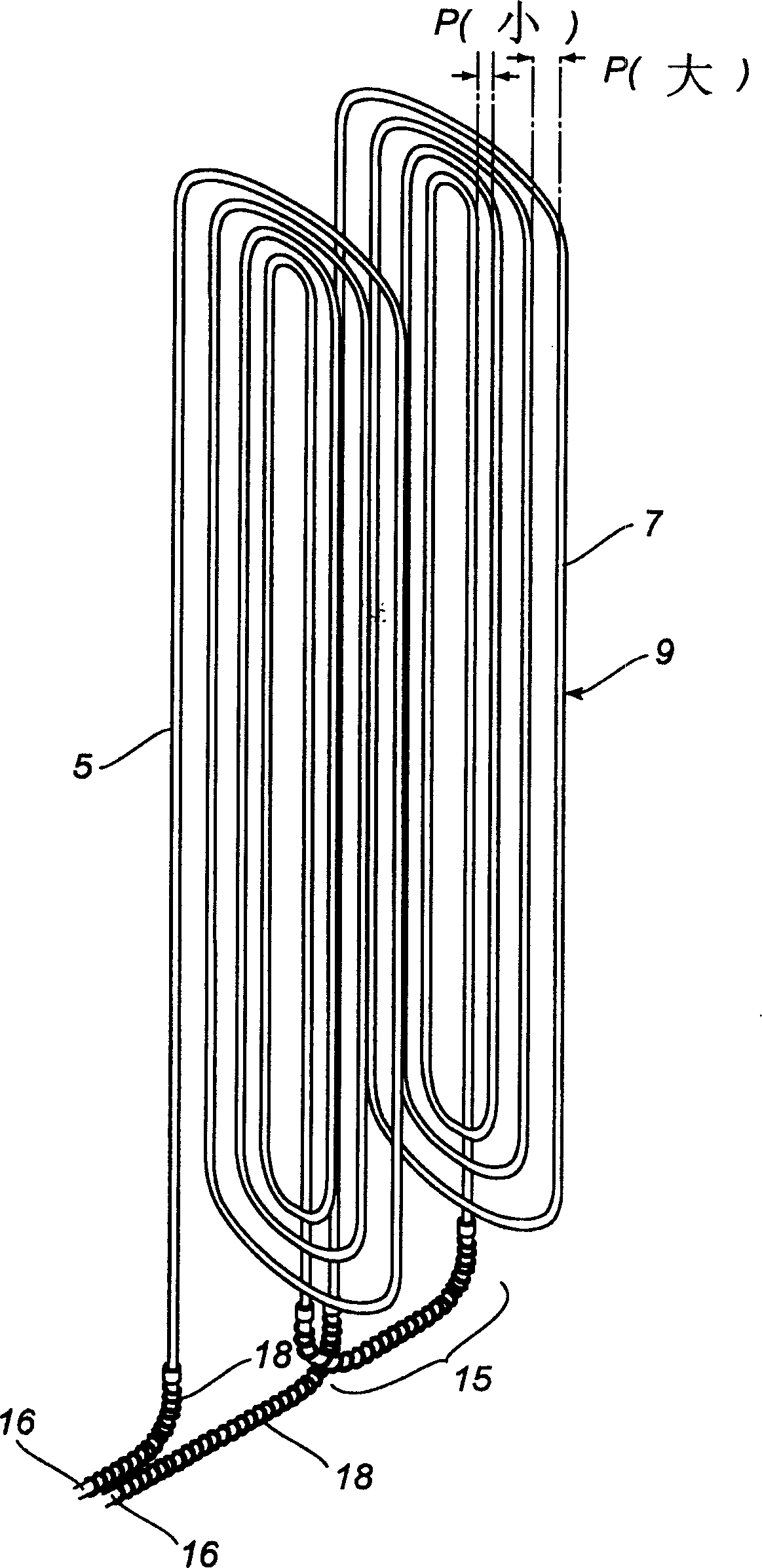

[0069] elephant figure 2 , image 3 As shown, the pair of workpiece coils 5 and 7 are composed of two helical parts formed by winding a single copper tube 9 made of a conductive material. Since the eddy currents cancel each other in the middle part of the spiral part, the output power is reduced, so the helical coil (P) is narrower than the peripheral part.

[0070] The two helical parts forming the workpiece coils 5 and 7 are connected by the middle part, and the two ends of the workpiece coils are cut and removed, and connected with a movable energized cooling hose 15 .

[0071] If formed as above, due to figure 2 As shown, the workpiece coils 5, 7 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com