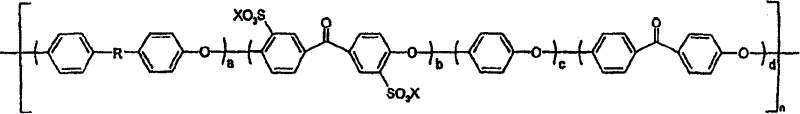

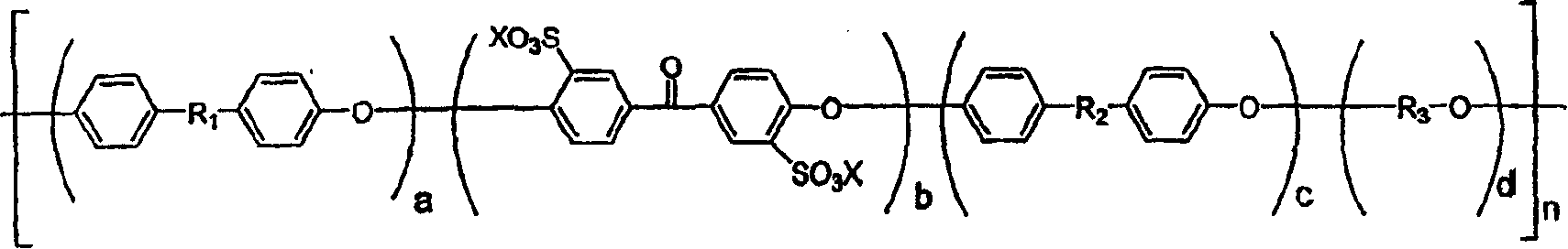

Sulfonated copolymer

A technology for sulfonated copolymers and comonomers, applied in the direction of electrochemical generators, chemical instruments and methods, structural parts, etc., can solve problems such as loss and battery performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

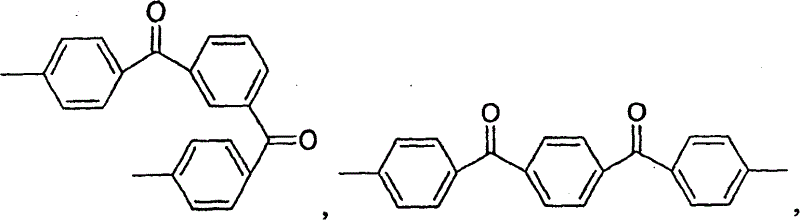

[0062] Sulfonated PEEK with bisphenol A composition

[0063] In a 500 ml three necked round bottom flask equipped with mechanical stirring, thermometer, nitrogen inlet and Dean-Stark trap / condenser, bisphenol A (9.128 g), 4,4'-difluoro Benzophenone (5.6732 g), sulfonated 4,4'-difluorobenzophenone (5.9108 g), anhydrous potassium carbonate (7.2 g) were dissolved in a mixture of DMSO and toluene (about 20% solids concentration) . The mixture was heated to reflux of toluene with stirring and held at 150°C for 4 hours, then the temperature was increased to 175-180°C and held for 6 hours. The reaction mixture was precipitated with acetone or methanol to obtain a crude product, which was then washed 4 times with hot water. The dry polymer was then dissolved in DMAC to make a 20% coating solution. The resulting 2 mil thick film was immersed in 1.5M H 2 SO 4 16 hours (overnight), followed by several rinses with deionized water until no residual H 2 SO 4 .

[0064] The polymer f...

Embodiment 2

[0069] Sulfonated PEEK with 50% bisphenol A and 50% hydroquinone composition

[0070] In a 500ml three necked round bottom flask equipped with mechanical stirring, thermometer, nitrogen inlet and Dean-Stark trap / condenser, bisphenol A (4.564g), hydroquinone (2.202g), 4,4'-difluorobenzophenone (5.6732 g), sulfonated 4,4'-difluorobenzophenone (5.9108 g) and anhydrous potassium carbonate (7.2 g) were dissolved in a mixture of DMSO and toluene ( The solids concentration is about 20%). The mixture was heated to reflux of toluene with stirring at 150°C for 4 hours, then the temperature was increased to 180°C and held for 6 hours. The reaction mixture was precipitated with acetone or methanol to obtain a crude product, which was then washed 4 times with hot water. The dry polymer was then dissolved in DMAC to make a 20% coating solution. The resulting 2 mil thick film was immersed in 1.5M H 2 SO 4 16 hours (overnight), followed by several rinses with deionized water until no res...

Embodiment 3

[0073] Sulfonated PEEK with 4,4'-thiobisphenol composition

[0074] In a 500 ml three necked round bottom flask equipped with mechanical stirring, thermometer, nitrogen inlet and Dean-Stark trap / condenser, 4,4'-thiobisphenol (8.728 g), 4 , 4'-difluorobenzophenone (5.6732g), sulfonated 4,4'-difluorobenzophenone (5.9108g) and anhydrous potassium carbonate (7.2g) were dissolved in a mixture of DMSO and toluene (solid concentration is about 20%). The mixture was heated to reflux of toluene with stirring and held at 150°C for 4 hours, then the temperature was increased to 175-180°C and held for 6 hours. The reaction mixture was precipitated with acetone or methanol to obtain a crude product, which was then washed 4 times with hot water.

[0075] Conductivity of the membrane: 0.021S / cm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com