Making process of tritium luminotron

A technology of a light-emitting tube and a manufacturing method, which are applied in the manufacture of discharge tubes/lamps, cold cathode manufacture, electrode system manufacture, etc., to achieve the effects of high safety, cost saving, and ease of manufacture and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

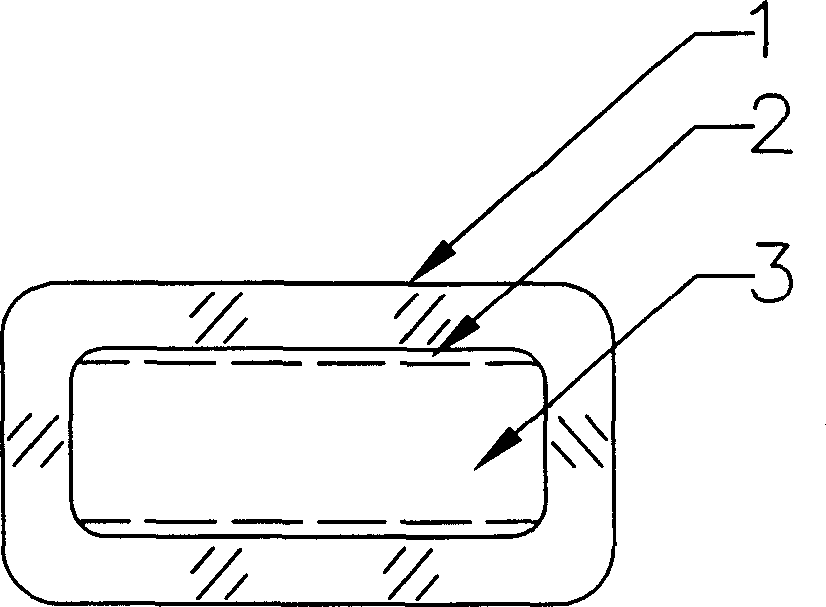

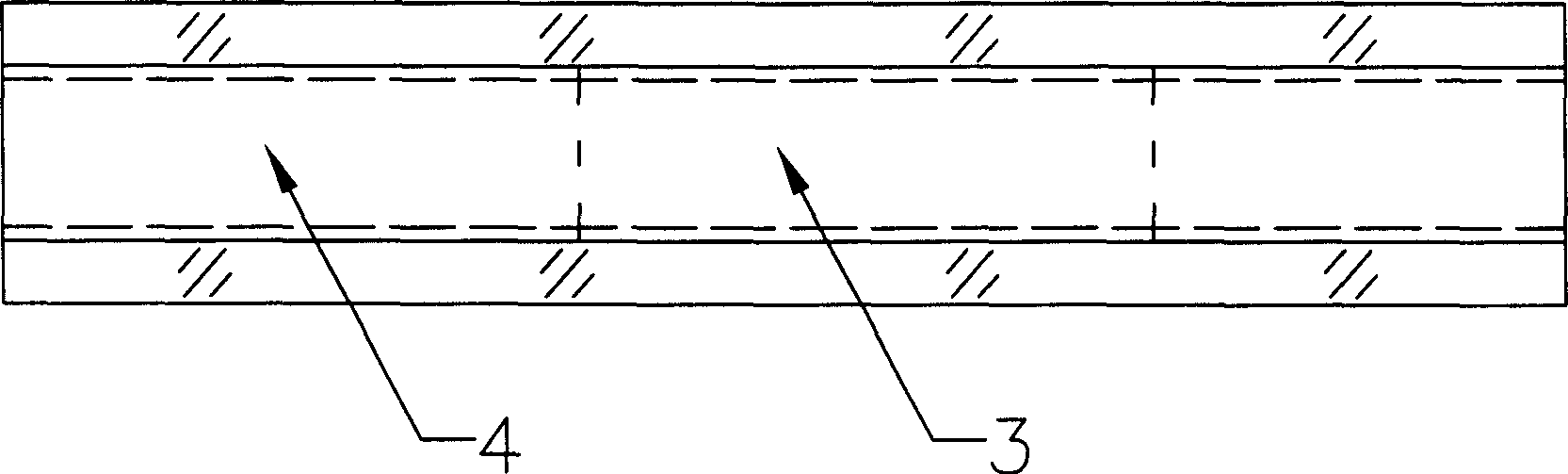

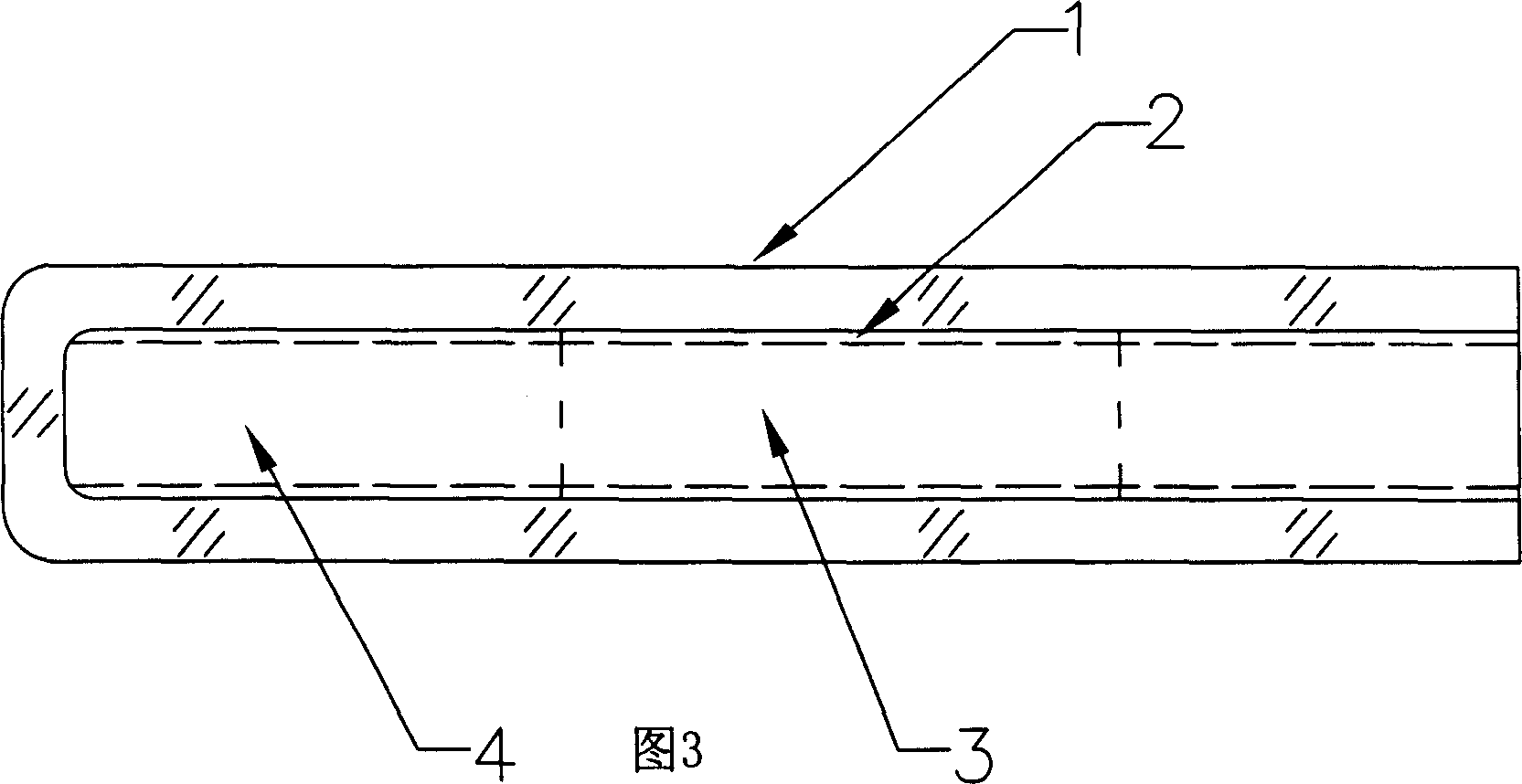

[0052] (a) Selection of glass tube coated with phosphor layer:

[0053]According to the size and luminous color requirements of the tritium luminous tube, select the corresponding glass tube coated with phosphor powder based on ZnS; the size ratio of the attached cavity 4 of the glass tube coated with the phosphor layer and the inner cavity 3 of the tritium luminous tube is 1:1 .

[0054] The size of the selected glass tube (produced by Changchun Optical Machinery Institute of Chinese Academy of Sciences) coated with the phosphor layer (green): inner diameter 0.6mm, length 10mm, wall thickness 0.2mm

[0055] (b) Port sealing on the 4 side of the attached chamber of the glass tube: use a flame sealing machine for single-end sealing;

[0056] (c) Put the titanium metal rod or titanium metal sponge 5 (manufactured by Beijing Atomic High Technology Application Co., Ltd.) that absorbs tritium gas into the attached chamber 4 of the sealed single-ended glass tube:

[0057] The sele...

Embodiment 2

[0067] (a) Selection of glass tube coated with phosphor layer:

[0068] According to the size and color requirements of the tritium luminous tube, choose a glass tube coated with phosphor powder (ZnS as the matrix) layer. The size ratio of the attached cavity 4 of the glass tube coated with the phosphor layer and the inner cavity 3 of the tritium luminescent tube is 1:1.

[0069] The selected phosphor layer (blue) glass tube (produced by Shanghai Kerun Photoelectric Material Co., Ltd.) size: inner diameter 2mm, length 35mm, wall thickness 0.2mm;

[0070] (b) Port sealing on the 4 side of the attached chamber of the glass tube: use a flame sealing machine for single-end sealing;

[0071] (c) Put the titanium metal rod or titanium metal sponge 5 (manufactured by Beijing Atomic High Technology Application Co., Ltd.) that absorbs tritium gas into the attached chamber 4 of the sealed single-ended glass tube:

[0072] The selected titanium metal rod for absorbing tritium gas: 1.6m...

Embodiment 3

[0082] (a) Selection of glass tube coated with phosphor layer:

[0083] According to the size and color requirements of the tritium luminous tube, choose a glass tube coated with phosphor powder (ZnS as the matrix) layer. The size ratio of the attached cavity 4 of the glass tube coated with the phosphor layer and the inner cavity 3 of the tritium luminescent tube is 1:1.

[0084] The size of the selected glass tube (Changchun Kerun Photoelectric Material Co., Ltd.) coated with phosphor powder (red) layer: inner diameter 3mm, length 68mm, wall thickness 0.5mm

[0085] (b) Port sealing on the 4 side of the attached chamber of the glass tube: use a flame sealing machine for single-end sealing;

[0086] (c) Put the titanium metal rod or titanium metal sponge 5 (produced by Beijing Atomic High-tech Application Co., Ltd.) that absorbs tritium gas into the attached chamber 4 of the sealed single-ended glass tube;

[0087] Titanium sponge that absorbs tritium gas is selected: the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com