Test tube holder

A technology for cages and test tubes, applied in test tube holders/clamps, instruments, paving details, etc., can solve problems such as troublesome maintenance, poor assembly processability, and high manufacturing costs, and achieve lower prices, lower damage possibilities, and excellent durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

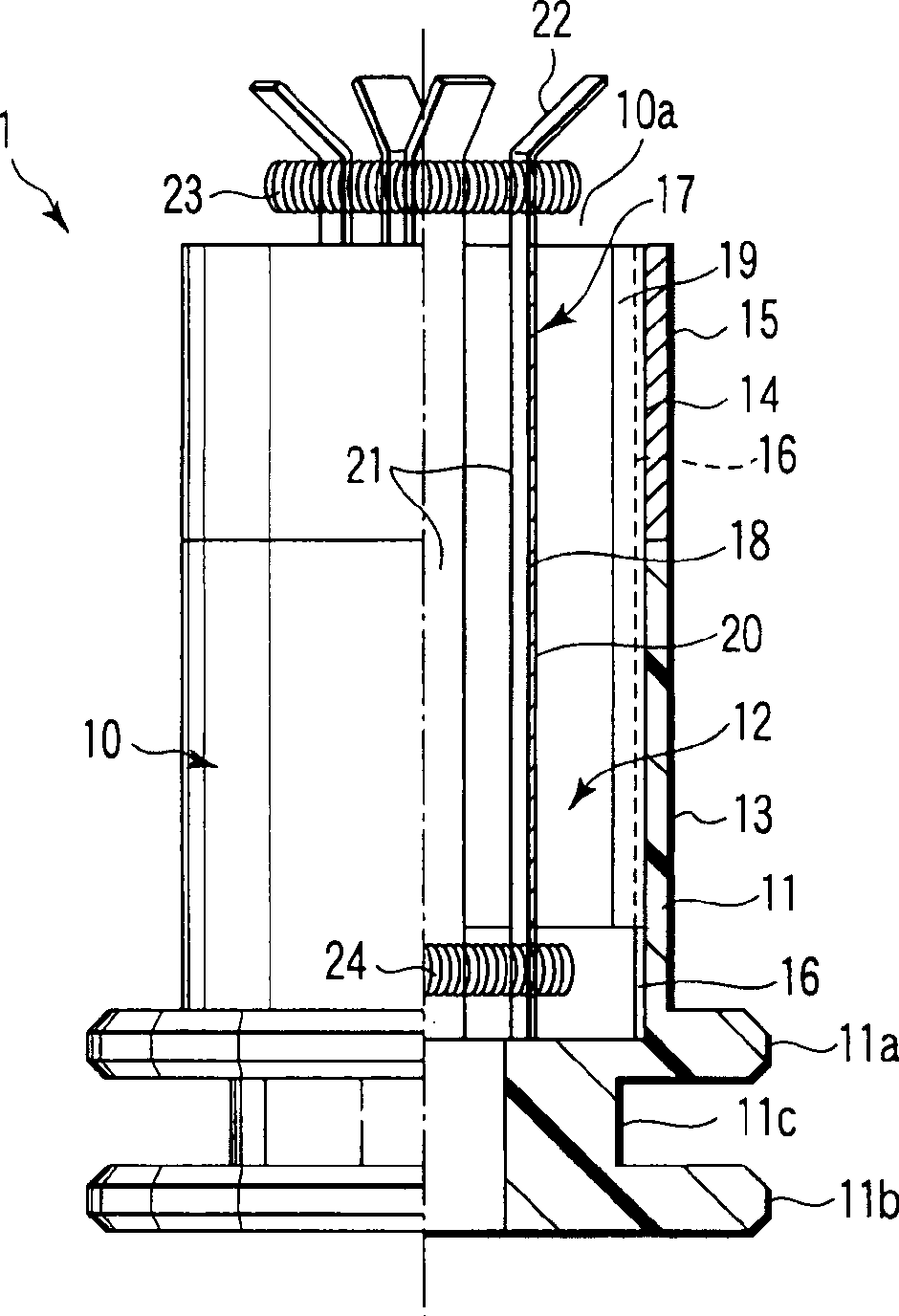

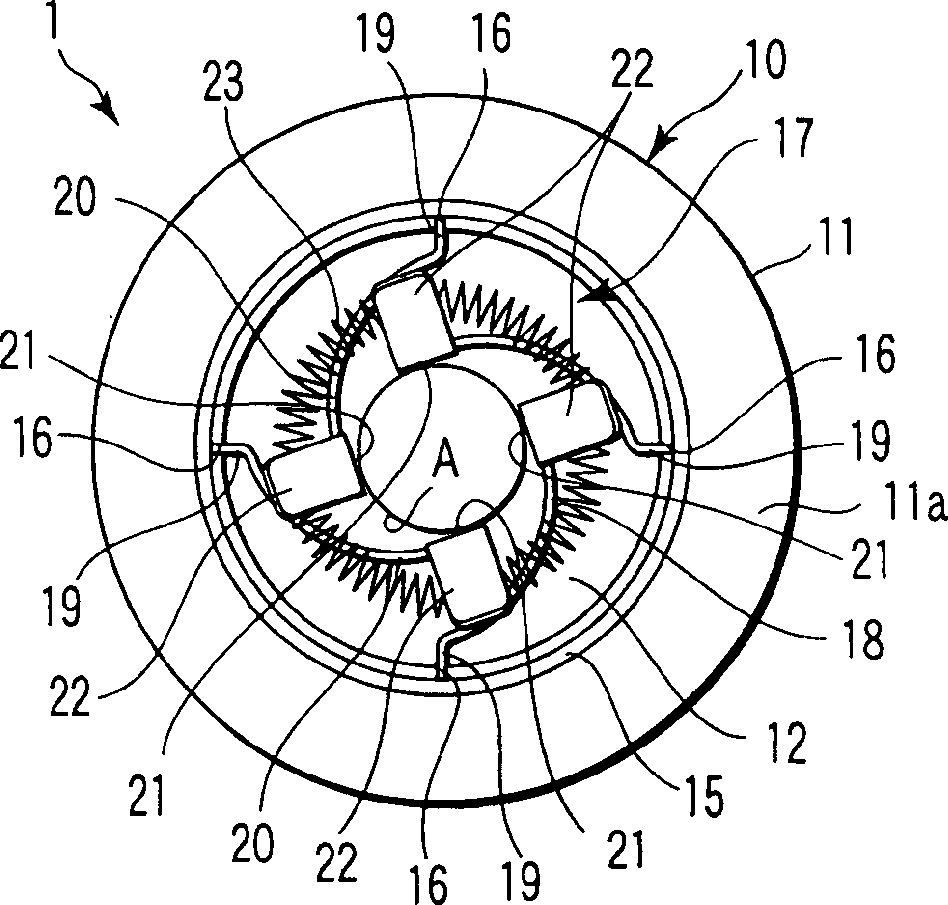

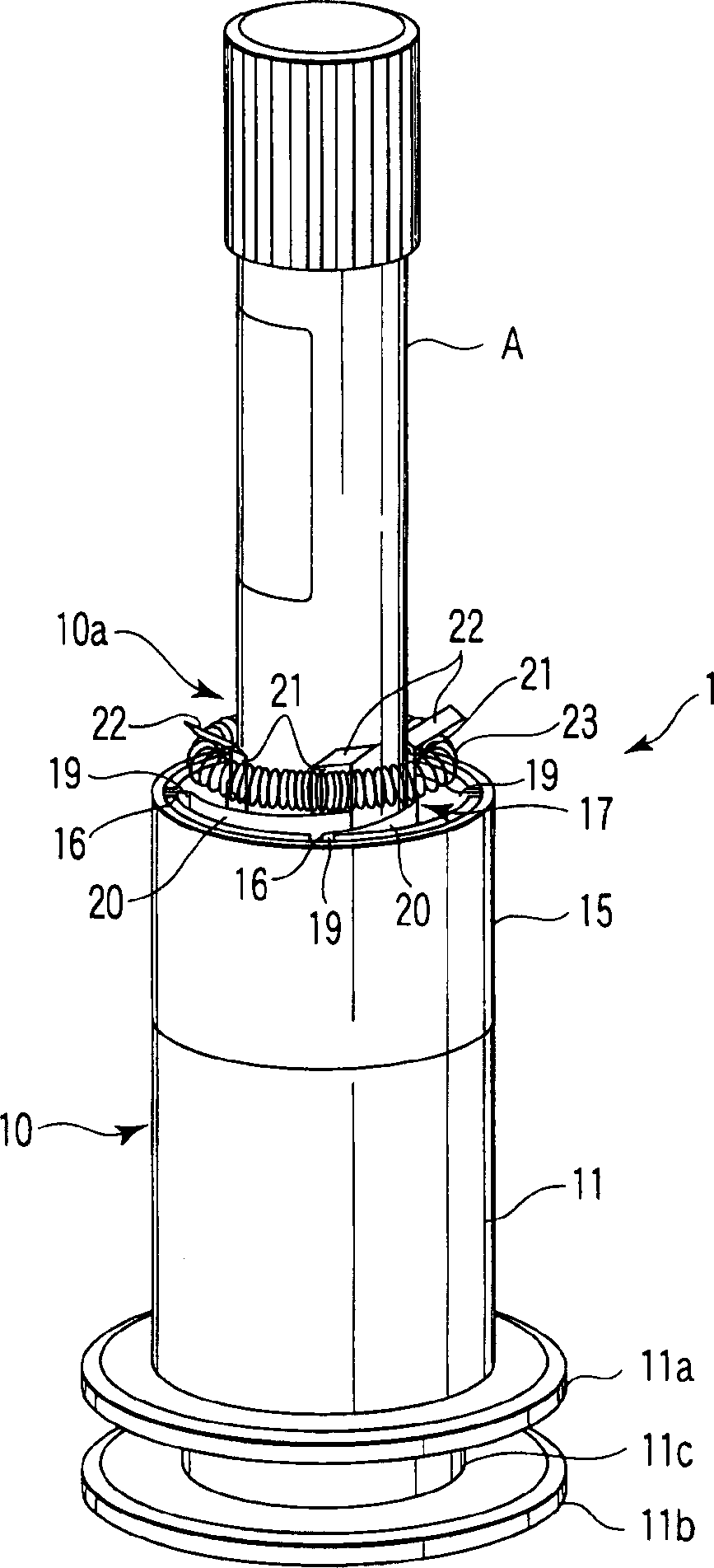

[0016] Below to Figure 1 ~ Figure 3 The test tube holder 1 of the embodiment of the present invention will be described in detail.

[0017] The test tube holder 1 of the embodiment of the present invention has a holder main body 10 and a test tube fixing adapter 17 . The holder main body 10 is formed of a synthetic resin material. In the holder main body 10, the joint part that can be connected with the transfer system guide rail (not shown), that is, the vertical two-layer flange parts 11a and 11b in the embodiment, is formed on the outer peripheral surface of the proximal part of the cylindrical base 11 , and an annular groove 11c is provided between the flange portions.

[0018] At the axial center portion of the cylindrical base 11, a cylindrical hollow portion 12 for inserting a test tube is provided at a depth from the tip end portion to a position corresponding to the flange portion 11a located on the upper stage. The outer periphery of the middle region of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com