Active lime producing process

A technology of active lime and production process, applied in the field of active lime production technology, can solve the problems of low output, low activity, low ash yield per ton of fuel, etc., and achieve high output, increased daily output, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

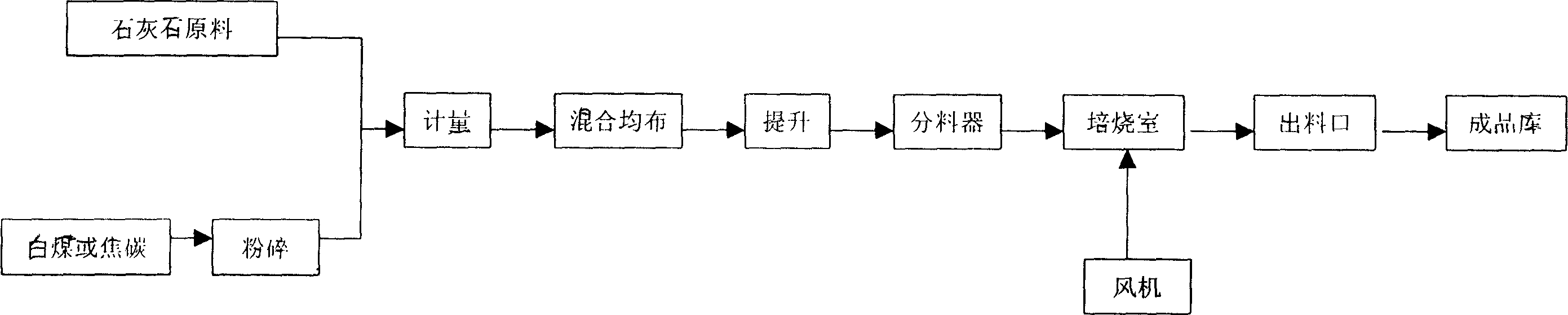

[0007] As shown in the figure, first make limestone of different sizes into 0.5-1cm particles, crush white coal or coke into powder, then put the limestone particles into the mixer, spray mist in the mixer, and at the same time Mix white coal or coke powder into the mixer, when the limestone particles are coated with a layer of white coal or coke powder, send it to the top of the kiln, and pour it into the kiln through the distributor, the highest temperature layer in the kiln The temperature is 1100°C±100°C, the fan supplies air to the kiln from the bottom, and the active lime leaks out from the bottom of the kiln.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com