Method for preparing mercaptosilicane coupling agent with low VOC (volatile organic compounds) emission

A technology of mercaptosilane coupling agent and chloropropyltrichlorosilane, which is applied in the field of preparation of mercaptosilane coupling agent, can solve the problems of large waste water discharge, scorched rubber material, and increased porosity of rubber, and achieve product High quality, low cost, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

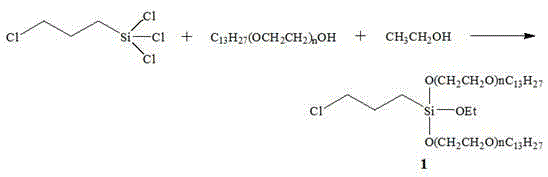

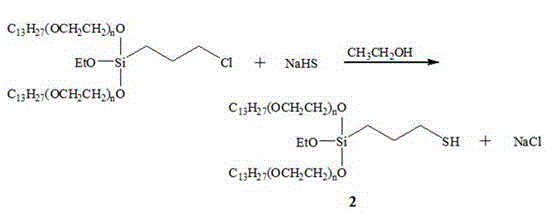

Embodiment 1

[0022] Drop into 212g of chloropropyltrichlorosilane in a 2000ml four-necked reaction flask with magnetic stirring, constant pressure dropping funnel and low temperature condenser, and drop into 841g of isomeric tridecyl alcohol polyoxyethylene ether in the constant pressure dropping funnel, Start the magnetic stirring, raise the temperature to 130°C, start the circulating water vacuum pump, and start the dropwise addition of isotridecyl alcohol polyoxyethylene ether to carry out the primary esterification reaction. The reaction time is 4 hours, and the hydrogen chloride gas generated by the reaction is absorbed by water. After the isomeric tridecyl alcohol polyoxyethylene ether dropwise reaction is completed, keep the reaction temperature of the system at 130°C, add 46g of ethanol to the constant pressure dropping funnel at the same time, continue to add ethanol dropwise for secondary esterification reaction, and the reaction time for 2 hours. After the reaction, 980 g of iso...

Embodiment 2

[0025] Drop into 212g of chloropropyltrichlorosilane in a 2000ml four-necked reaction flask with magnetic stirring, constant pressure dropping funnel and low temperature condenser, and drop into 841g of isomeric tridecyl alcohol polyoxyethylene ether in the constant pressure dropping funnel, Start the magnetic stirring, raise the temperature to 120°C, start the circulating water vacuum pump, and start the dropwise addition of isotridecyl alcohol polyoxyethylene ether to carry out the primary esterification reaction. The reaction time is 6 hours, and the hydrogen chloride gas generated by the reaction is absorbed by water. After the isomeric tridecyl alcohol polyoxyethylene ether dropwise reaction is completed, keep the reaction temperature of the system at 120°C, add 46g of ethanol to the constant pressure dropping funnel at the same time, continue to add ethanol dropwise to carry out the secondary esterification reaction, and the reaction time for 3 hours. After the reaction,...

Embodiment 3

[0028] Drop into 212g of chloropropyltrichlorosilane in a 2000ml four-necked reaction flask with magnetic stirring, constant pressure dropping funnel and low temperature condenser, and drop into 841g of isomeric tridecyl alcohol polyoxyethylene ether in the constant pressure dropping funnel, Start the magnetic stirring, raise the temperature to 110°C, start the circulating water vacuum pump, and start the dropwise addition of isotridecyl alcohol polyoxyethylene ether to carry out the primary esterification reaction. The reaction time is 8 hours, and the hydrogen chloride gas generated by the reaction is absorbed by water. After the isomeric tridecyl alcohol polyoxyethylene ether dropwise reaction is completed, keep the reaction temperature of the system at 110°C, add 46g of ethanol to the constant pressure dropping funnel at the same time, continue to add ethanol dropwise for secondary esterification reaction, and the reaction time for 4 hours. After the reaction finishes, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com