Manufacturing method of intermediate body of multilayer ceramic capacitor

A technology of laminated ceramics and a manufacturing method, which is applied in the direction of laminated capacitors, fixed capacitance parts, fixed capacitor dielectrics, etc., can solve the problems of internal electrode 3 burying, etc., and achieve good yield, improved productivity, and good adhesion Effect

Active Publication Date: 2019-06-25

HOKURIKU ROKA CO LTD

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

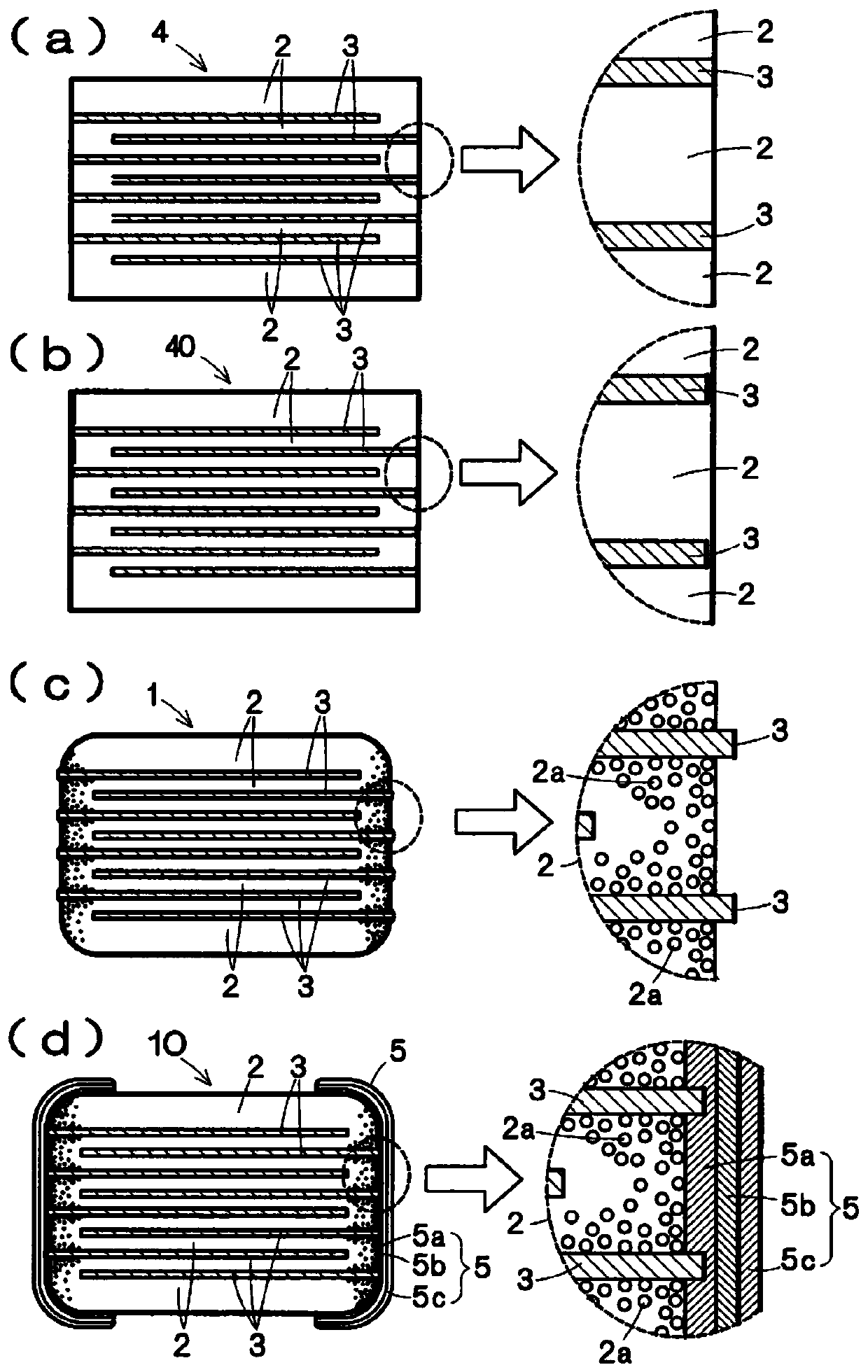

In the intermediate body 4 of the multilayer ceramic capacitor before sintering, such as Figure 118 As shown in (a), the end faces of the internal electrodes 3 are exposed to the outside from the end faces of the ceramic layer 2, but if they are sintered, then Figure 118 As shown in (b), the internal electrode 3 is buried in the ceramic layer 2 due to the difference in thermal expansion rate or thermal contraction rate between the ceramic layer 2 and the internal electrode layer 3.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~113

[0241] sample

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

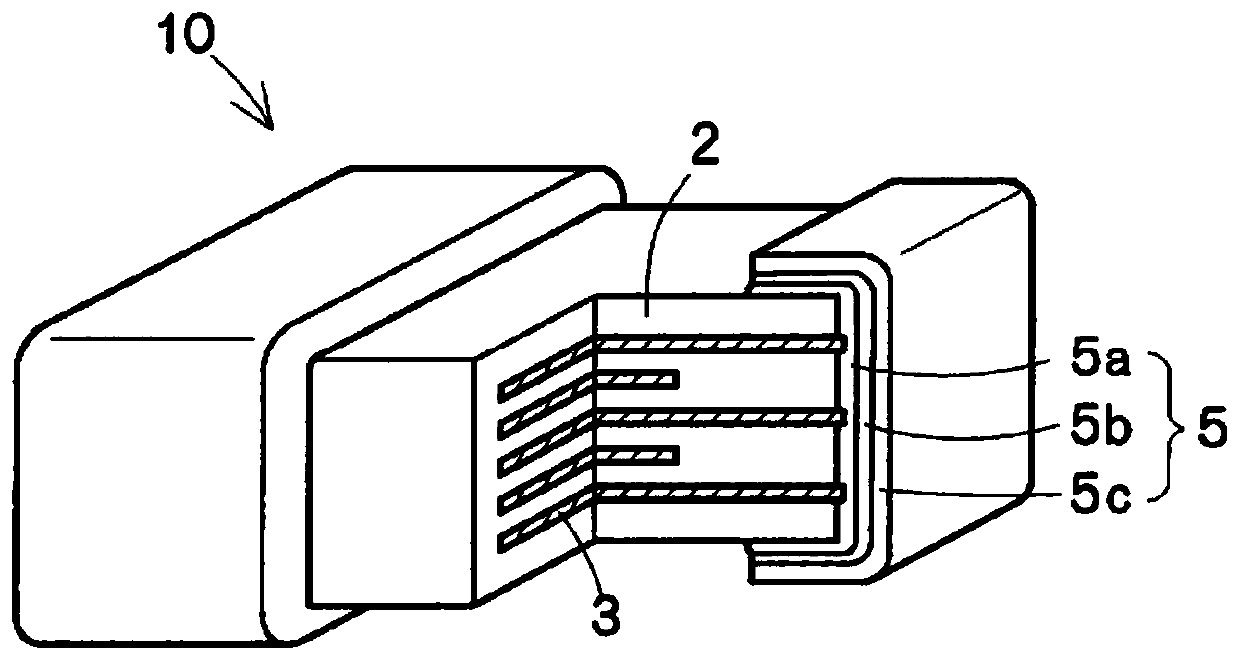

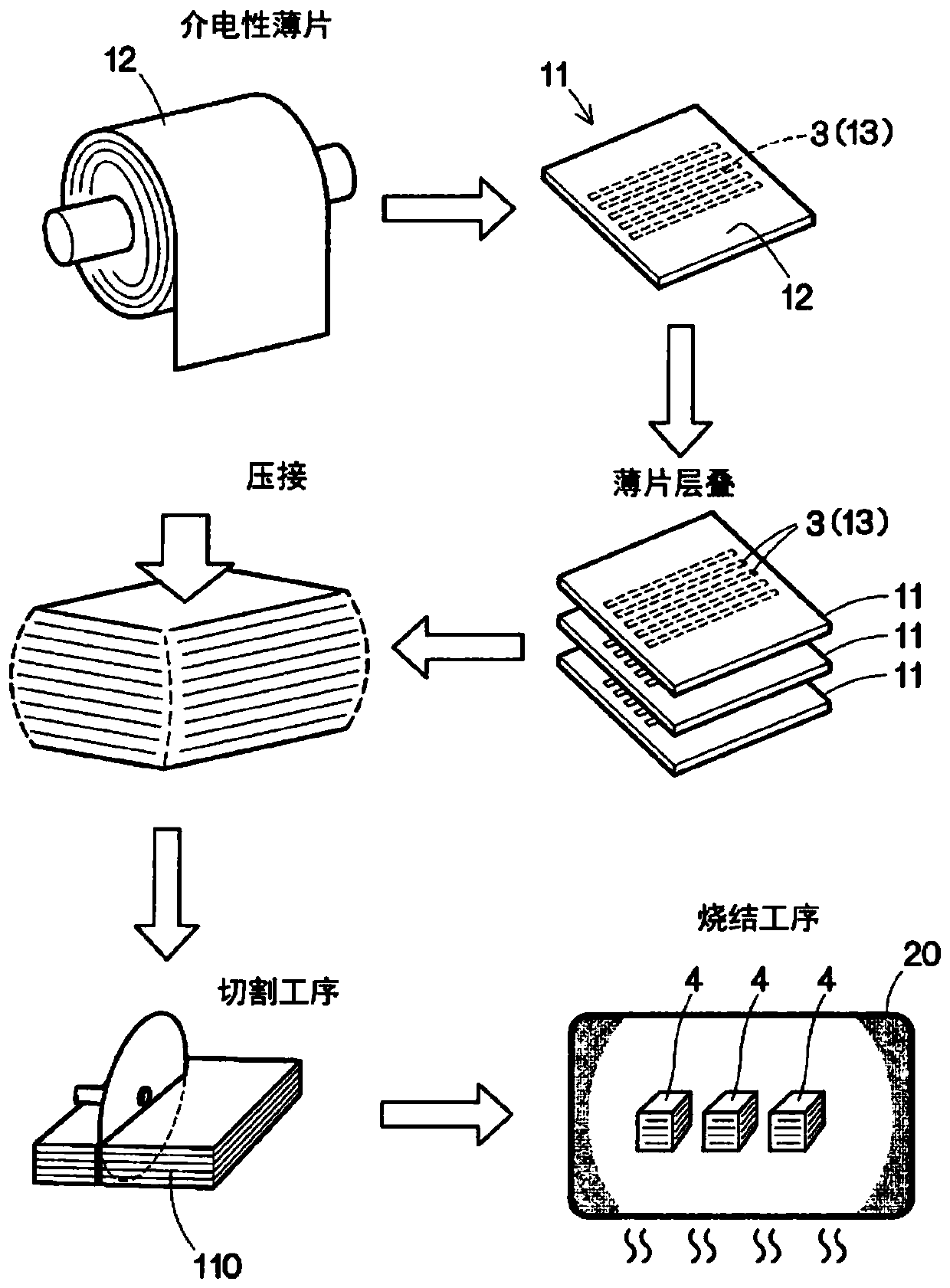

The present invention provides an intermediate body of a multilayer ceramic capacitor capable of remarkably improving productivity, having excellent adhesion between internal electrodes and external electrodes, high reliability, excellent yield rate, and high and stable electrical characteristics, etc. Manufacturing method, aqueous treatment solution containing halogen compound used in manufacturing intermediate of laminated ceramic capacitor, intermediate of laminated ceramic capacitor, method of manufacturing laminated ceramic capacitor and laminated ceramic capacitor; in manufacturing laminated ceramic capacitor In the case of an intermediate body (1) of a ceramic capacitor, ceramic layers (2) and internal electrodes (3) are alternately laminated in multiple layers, and the laminate is crimped and cut to obtain an intermediate body (4) of a laminated ceramic capacitor Thereafter, the intermediate body (4) is sintered, and then at least an end portion of the intermediate body (40) of the sintered laminated ceramic capacitor is brought into contact with an aqueous treatment solution containing a halogen compound, whereby the ceramic layer (2 ) is etched to expose the end face or end portion of the internal electrode (3) buried in the ceramic layer (2) toward the outside from the end face (2) of the ceramic layer; treatment of the aqueous solution; in addition, external electrodes (5) are provided at both ends or side surfaces of the intermediate body (1) of the obtained laminated ceramic capacitor in such a manner as to be electrically connected to the internal electrodes, thereby obtaining a laminated ceramic capacitors (10).

Description

technical field [0001] The present invention relates to a method for producing an intermediate body of a laminated ceramic capacitor, a treatment aqueous solution containing a halogen compound used in the production of an intermediate body of a laminated ceramic capacitor, an intermediate body of a laminated ceramic capacitor, and production of a laminated ceramic capacitor method and multilayer ceramic capacitors. Background technique [0002] Conventionally, in multilayer ceramic capacitors, ceramic layers and internal electrodes are alternately stacked in multiple layers, and the laminate is crimped and cut to obtain a green chip, that is, a green chip for multilayer ceramic capacitors. Thereafter, the green body for a laminated ceramic capacitor is sintered, and then external electrodes are formed on both end faces of the green body for a laminated ceramic capacitor after sintering, thereby manufacturing (for example, refer to Patent Document 1 and Patent Document 2 ). ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01G4/30H01G4/12

CPCH01G4/12H01G4/30

Inventor 森家英幸森家圭一郎森家洋晃

Owner HOKURIKU ROKA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com