Reinforced concrete structure plate and its prepn process

A concrete structure and sheet technology, applied in the field of reinforcement materials, can solve the problems of reduced solvent resistance of products, poor resin-fiber interface, and difficulty in producing thin and long reinforcement sheets, etc. Stability and high ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

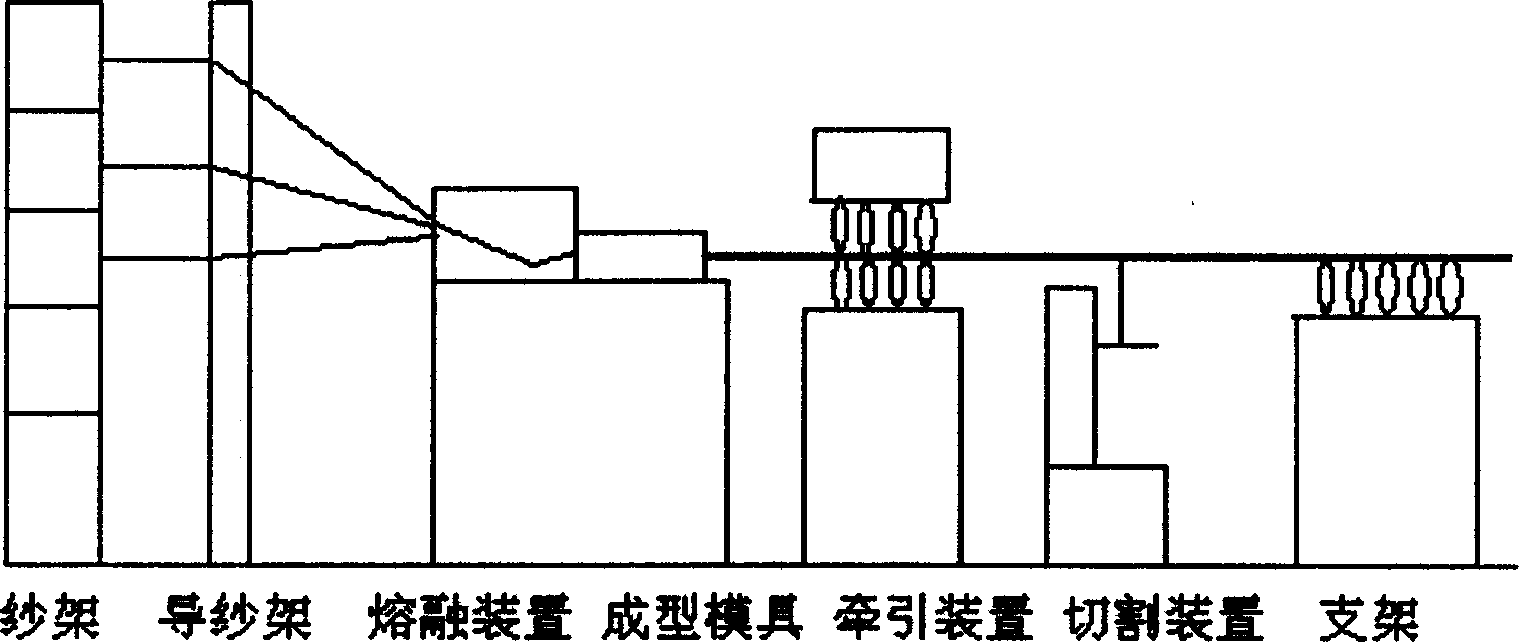

Image

Examples

Embodiment Construction

[0042] For structural reinforcement, it is necessary to use a matrix resin with good tensile strength, elastic modulus and ductility. This technology first proposes to use engineering plastic nylon 6 as the basic resin. Nylon 6 itself is not suitable for melt impregnation due to its high viscosity, but adding various additives for modification and rationally optimizing the matrix formula can significantly reduce the high-temperature melt viscosity of thermoplastic resins, greatly improve fluidity, and facilitate resin melts to infiltrate reinforcing fibers. It will not affect the mechanical properties and thermal properties of the original thermoplastic resin, can ensure smooth demoulding during pultrusion production, and the surface of the product is smooth, and the selected modifier is environmentally friendly and low-cost.

[0043] When the matrix formula is used to prepare continuous fiber-reinforced thermoplastic resin-based composite materials, melt impregnation is adopte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com