Longitudinal laying device of robot for building windbreak sand-fixating grass grid

A longitudinal and grass belt technology, applied in the field of windbreak and sand fixation automatic mechanical devices, can solve the problems of low efficiency, high cost and unsatisfactory effect, and achieve the effects of firm grass planting, high productivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

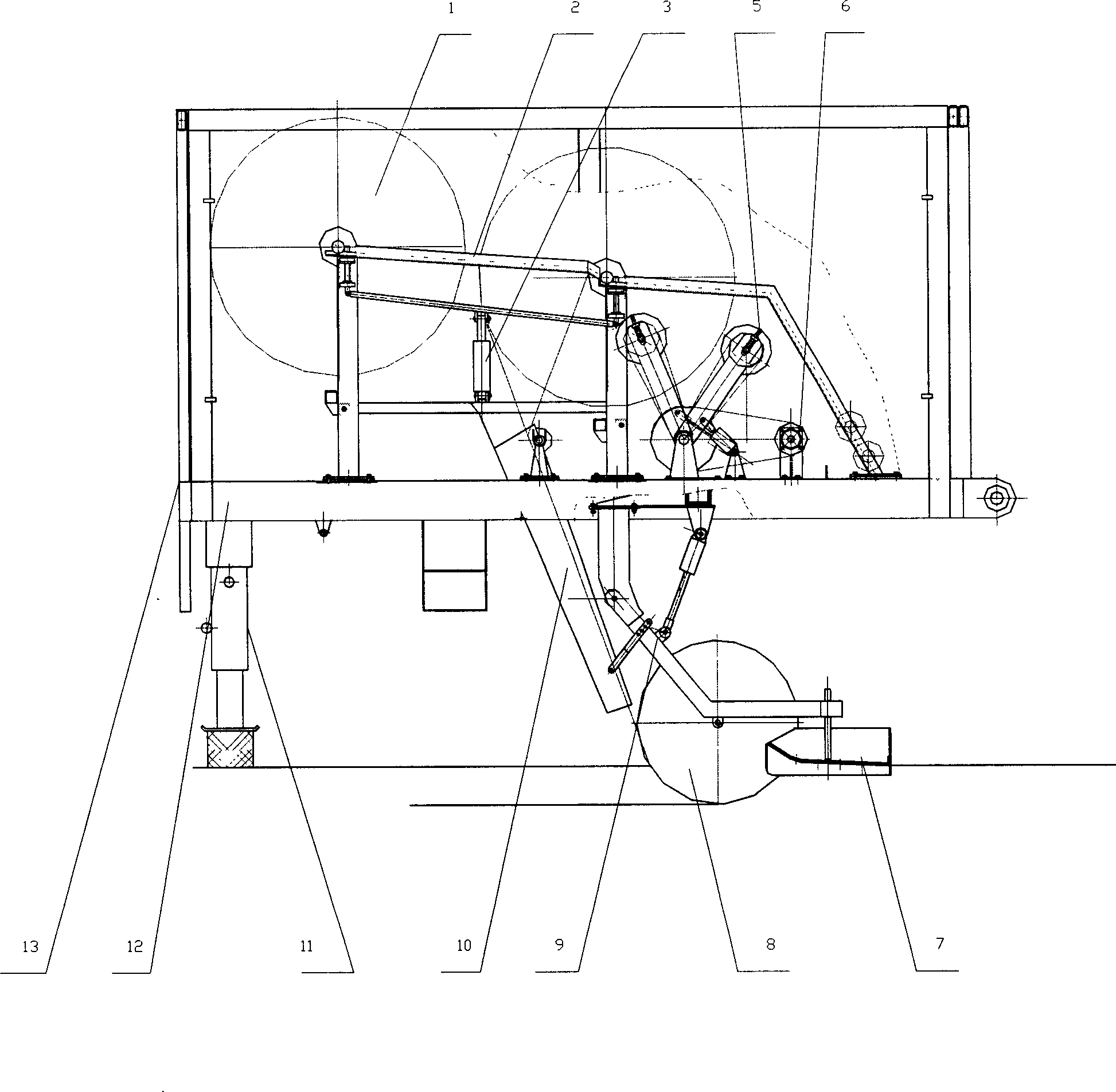

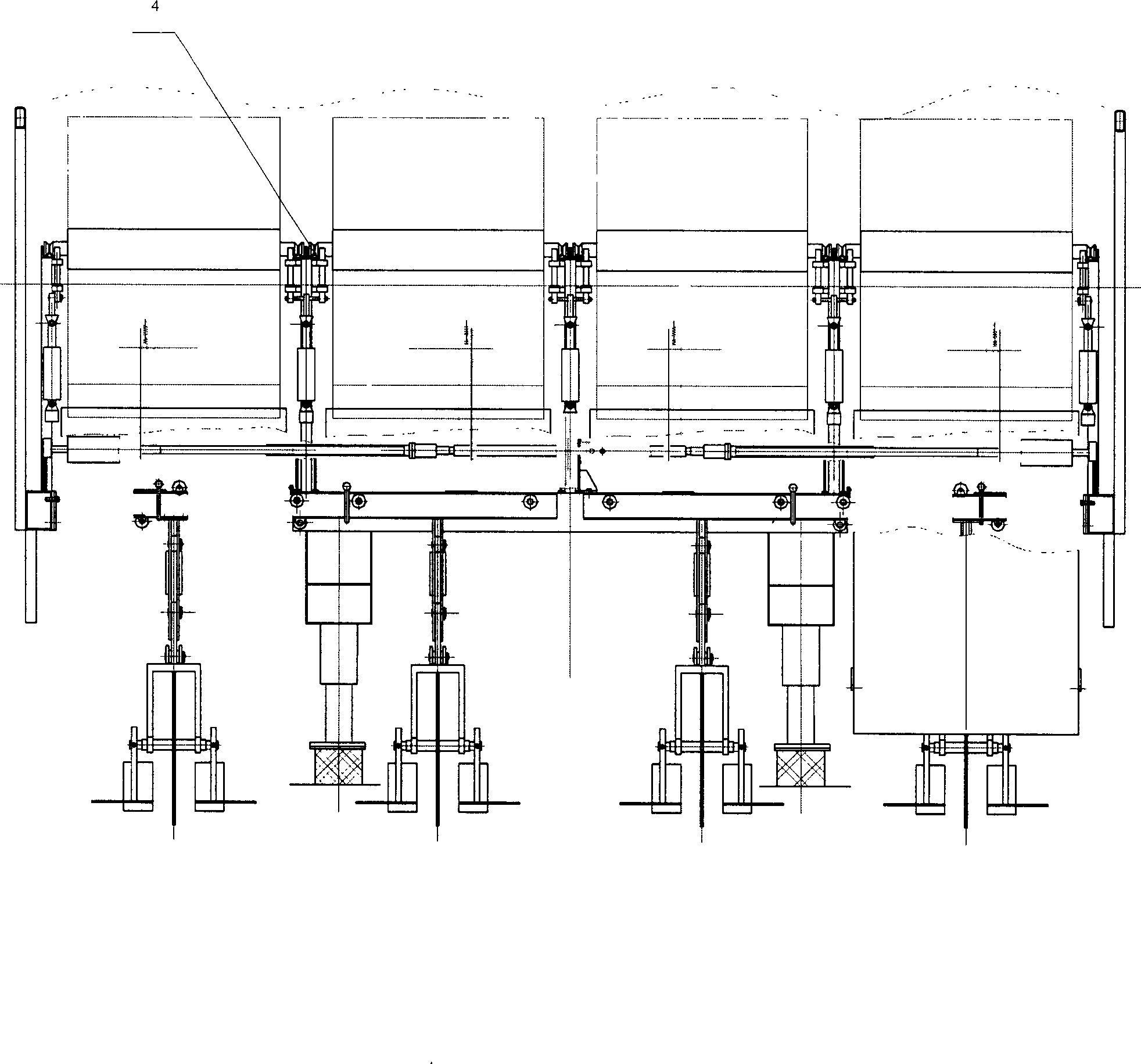

[0010] The grass roller power hydraulic motor 6 rotates, driving the belt conveying device 5 to act, and the grass belt is laid longitudinally from the working roller in the grass roller 1 to the ground along the grass protection conveying track 10; The device 8 is pressed down, and the longitudinal laying is started, and the sand covering device 7 is covered with sand; the longitudinal laying grass roller 1 has 2 groups of 8, the first group of 4 are working rollers, and the latter 4 are spare rollers, and one group of 4 working rollers , and only three of them are working at the same time. Due to the requirements of turning and laying, there is a grass roller on both sides that does not work. When the grass on the 3 working rollers is laid, the first group of 2 hydraulic cylinders in the hydraulic cylinder 3 (4 groups of 8 in total) will act, the automatic charging switch device 4 will act, and the grass-free steel roller, that is, the core rest Gravity slides down along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com