Manufacturing system for microstructure

A manufacturing system and microstructure technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of low moving speed, small stroke, etc., and achieve high precision and stroke characteristics, high vacuum applicability, Effect of large stroke characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

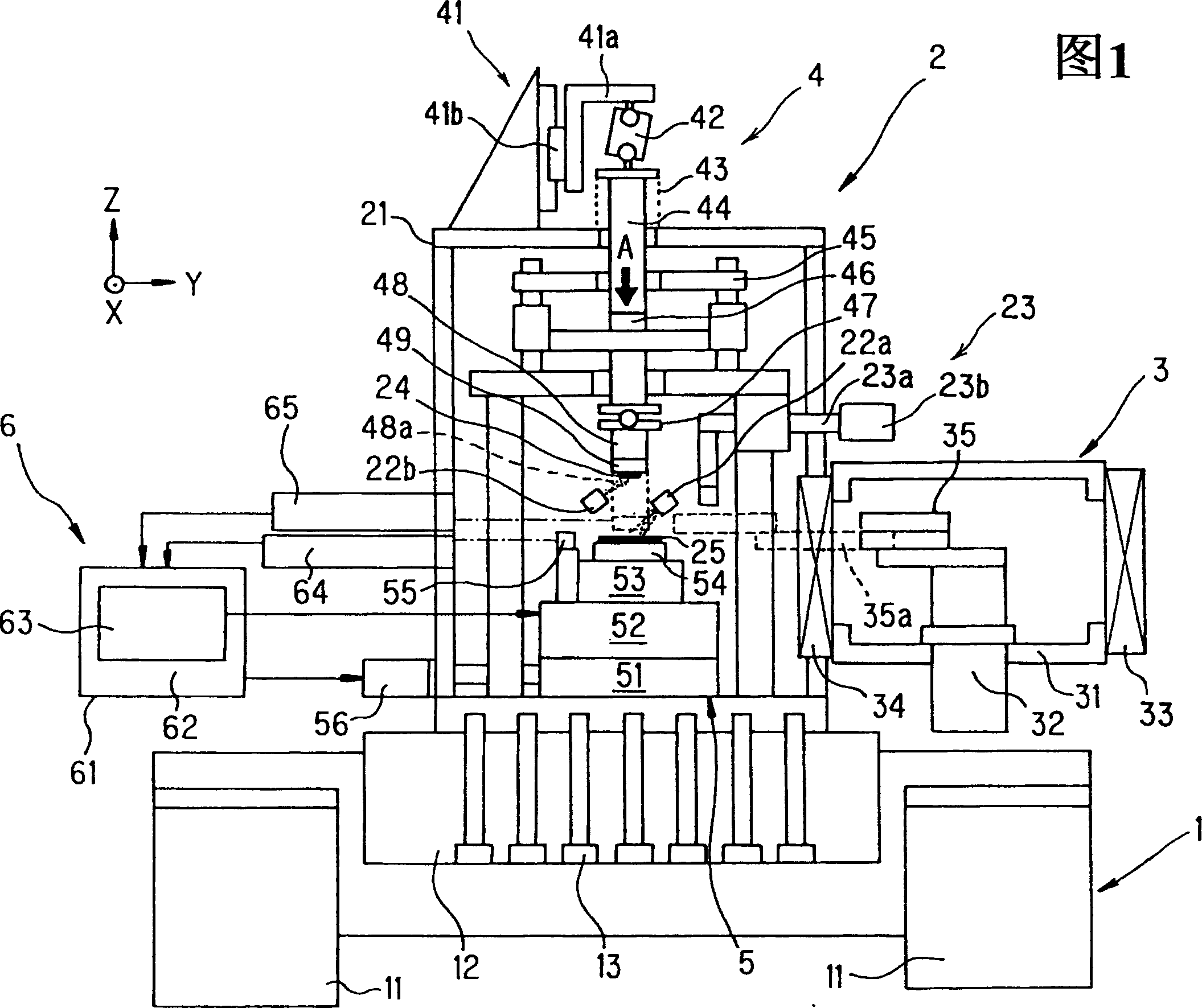

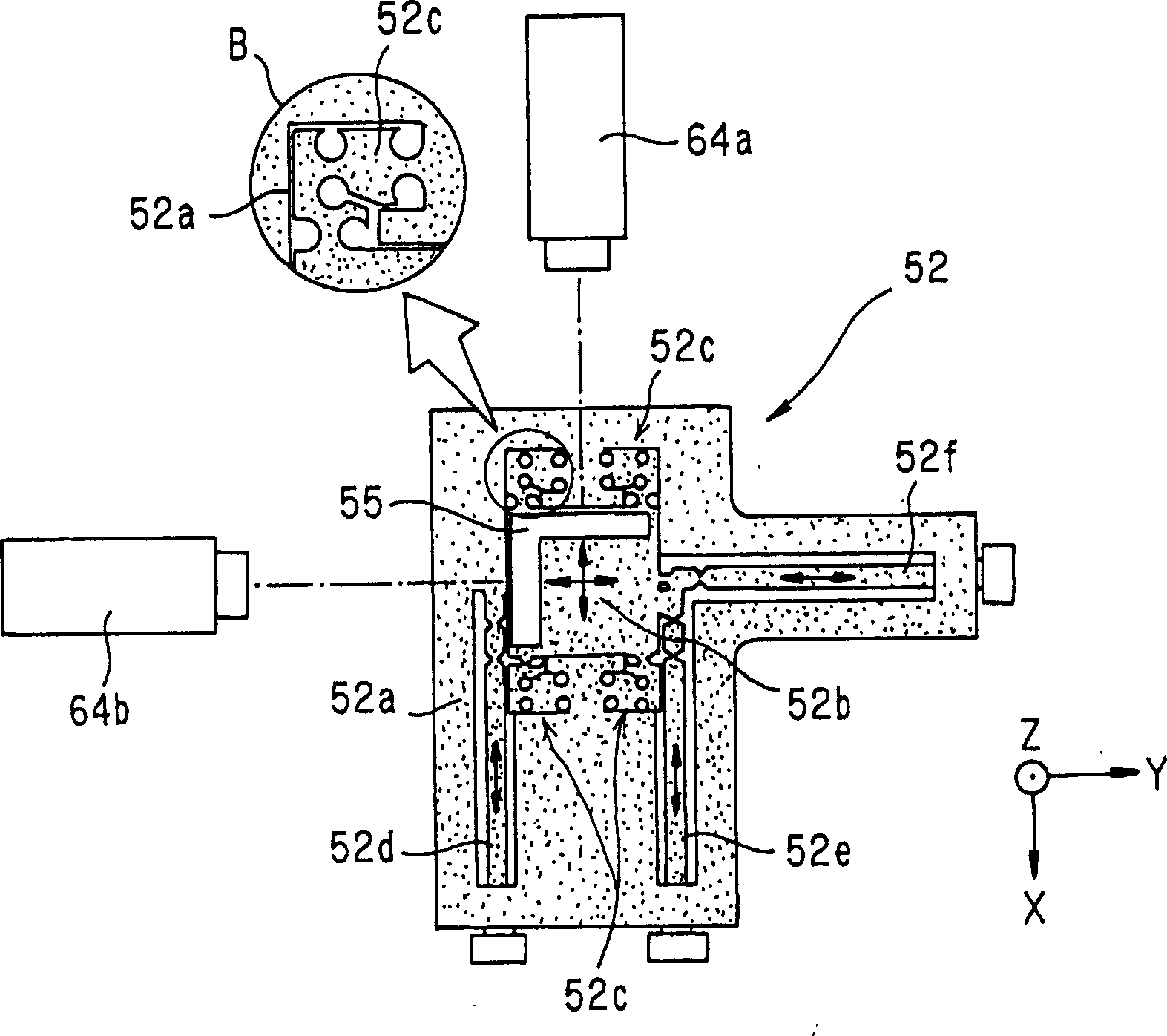

[0053] The microstructure manufacturing system according to the present invention is configured to combine and laminate a plurality of thin film elements and the like and thereby manufacture microstructures, by element positioning a plurality of thin film elements having arbitrary two-dimensional patterns or three-dimensional patterns, including a plurality of arbitrary two-dimensional A substrate (crimped member) of a pattern or a three-dimensional pattern or the like is set oppositely with respect to a crimping target member, then crimping and separation are performed, and then these steps are repeated.

[0054] In the microstructure manufacturing system according to the present invention, a high degree of positioning accuracy is obtained by using a table device, wherein a large-stroke coarse motion table (first table) with a preset positioning accuracy is provided with a Small-stroke micro-motion worktable (second workbench) with higher positioning accuracy of the worktable....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com