Non-aqueous/aqueous two-phase gel electrolyte, preparation and battery thereof

A gel electrolyte, electrolyte technology, used in primary batteries, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of non-aqueous / aqueous two-phase gel electrolyte membrane 1

[0028] First dissolve polyvinylidene fluoride (PVDF) in N,N-dimethylformamide (DMF) to form a 10% PVDF solution, then weigh 1.6g of methyl-butylimidazole hexafluorophosphate (BMIPF 6 ), and added to 4 g of the above PVDF solution, mixed evenly, and dried in a vacuum oven at 120° C. for 12 hours to obtain a hydrophobic gel electrolyte membrane.

[0029] The hydrophilic gel electrolyte membrane is formed by mixing 8g of 6mol / L potassium hydroxide aqueous solution with 2g of polyvinyl alcohol and gelling.

[0030] The non-aqueous / water two-phase gel electrolyte membrane is formed by directly pressing the above-mentioned hydrophobic gel electrolyte membrane and hydrophilic gel electrolyte membrane together.

Embodiment 2

[0031] Example 2 Preparation of non-aqueous / aqueous two-phase gel electrolyte membrane 2

[0032] First, dissolve vinylidene fluoride and hexafluoropropylene copolymer (P(VDF-HFP)) in N-methylpyrrolidone (NMP) to form a 10% P(VDF-HFP) solution, and then weigh 0.8g methyl -Octylpiperidine bis(trifluorosulfonyl)immonium salt (PP18TFSI), and added to 2g of the above P(VDF-HFP) solution, mixed evenly, and dried in a vacuum oven at 120°C for 12h , to obtain a hydrophobic gel electrolyte.

[0033] Hydrophilic gel electrolyte membrane is prepared by the following method:

[0034] Prepare the mixed solution according to the following ratio, stir it evenly, and use it as the polymer electrolyte precursor solution.

[0035] Acrylic: 12.5%

[0036] Crosslinking agent (N,N'-methylenebis(acrylamide)): 0.06%

[0037] KOH solution (10mol / L): 87.44%

[0038]Under stirring, 50 mg of 4% initiator (Na 2 SO 3 +K 2 S 2 o 8 1:1wt) solution, the hydrophilic gel electrolyte membrane will be...

Embodiment 3

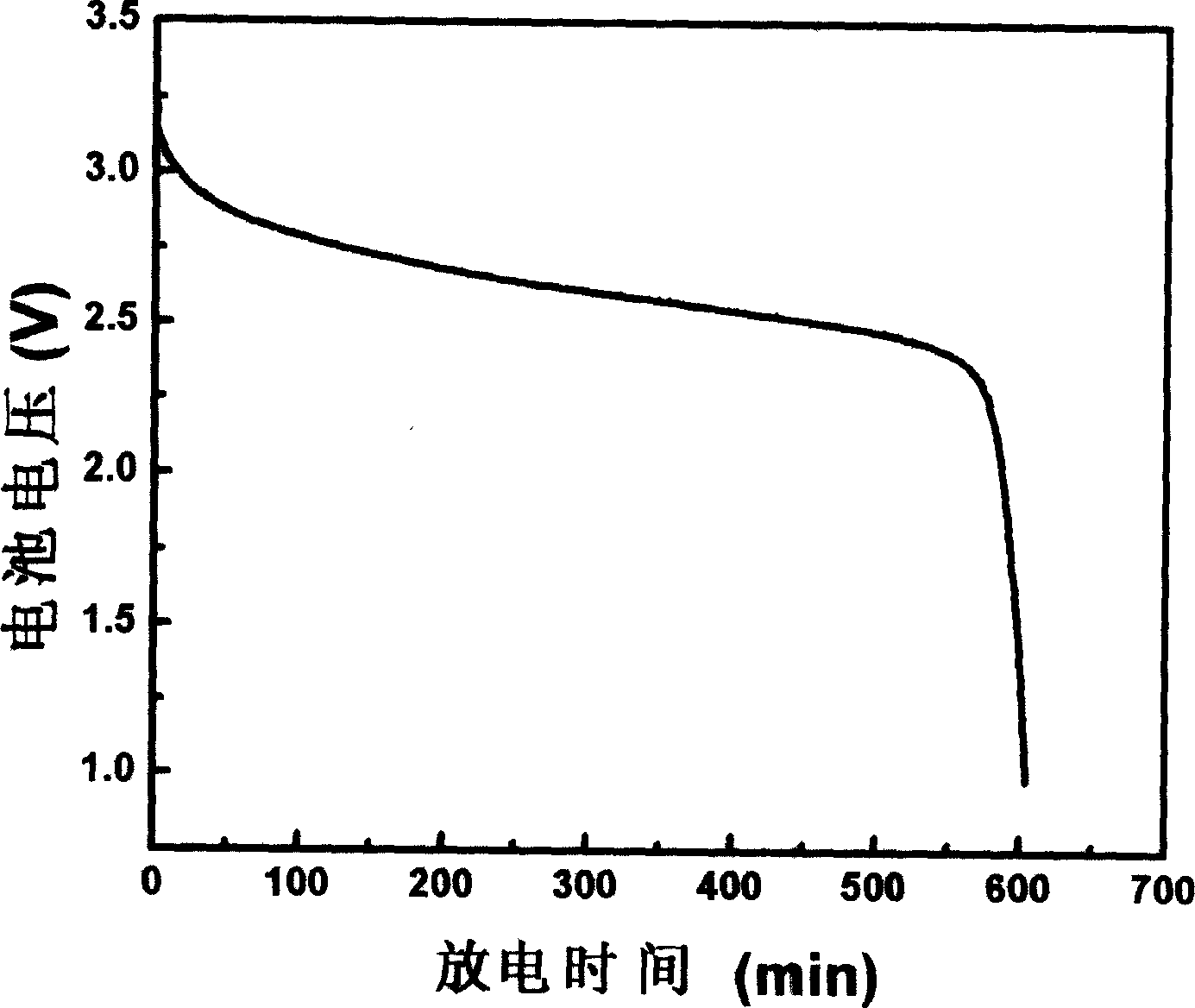

[0040] Example 3 Non-aqueous / aqueous two-phase gel electrolyte membrane used in lithium-air batteries

[0041] The positive electrode of the lithium-air electrode described in this example is a double-layer air electrode with manganese dioxide as a catalyst, the negative electrode is a metal lithium sheet, and the electrolyte is the non-aqueous / aqueous two-phase gel electrolyte membrane described in Example 2. The assembly of the battery is to put the catalytic layer of the air electrode close to the outside of the hydrophilic gel membrane of the non-aqueous / aqueous two-phase gel electrolyte membrane, and the metal lithium sheet is embedded in the hydrophobic gel of the non-aqueous / aqueous two-phase gel electrolyte membrane. inside the membrane. The lead wires drawn from the positive and negative poles are connected to a battery tester for discharge testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com