Glucomannan hydrogel of konnjaku and preparation method

A glucomannan water and gel technology, applied in the field of konjac glucomannan hydrogel, to achieve the effects of shortening the emergence cycle, mild reaction conditions, and improving moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

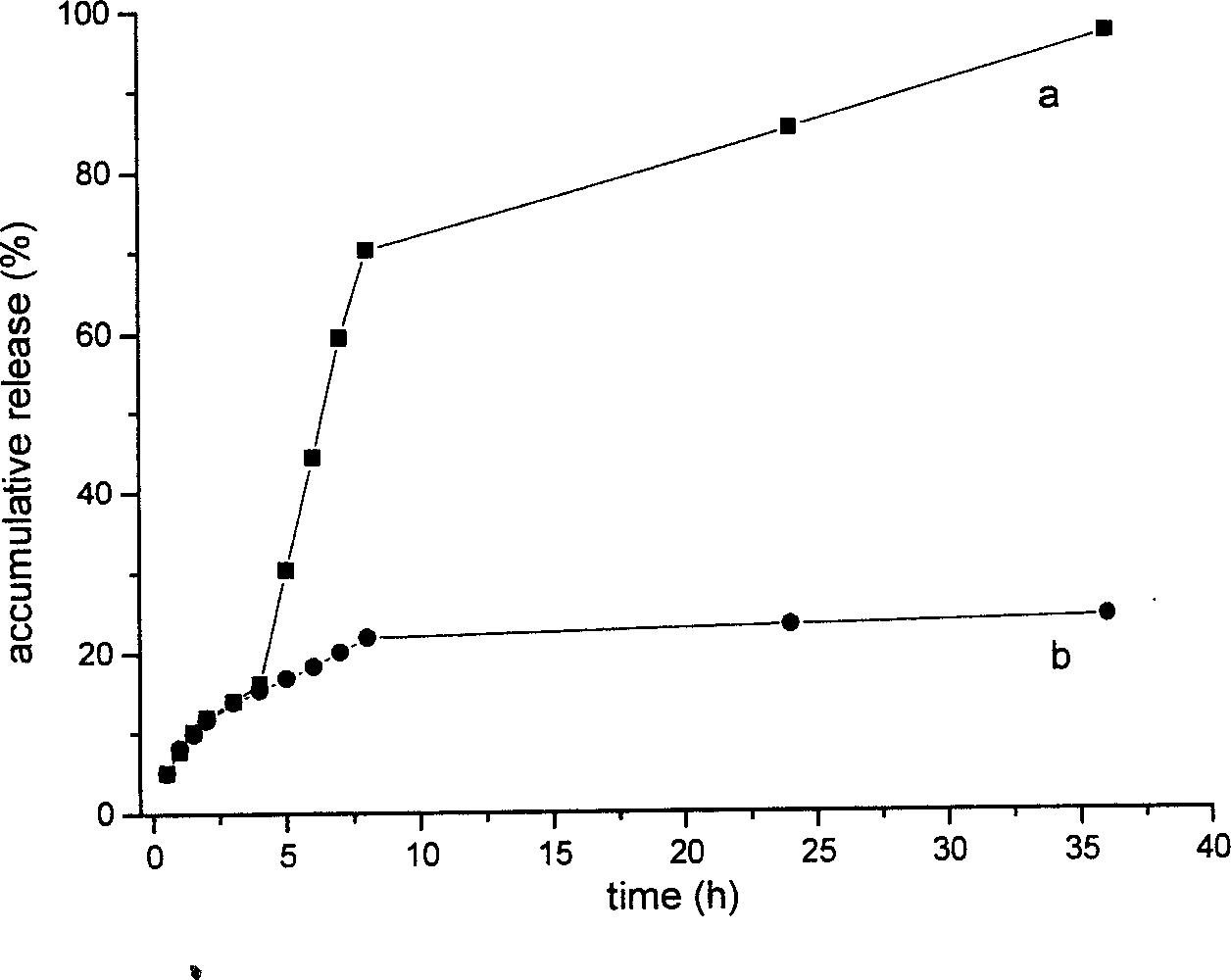

Image

Examples

Embodiment 1

[0032] a. Sodium hydroxide 0.04 parts

[0033] b. Distilled water 100 parts

[0034] c. Sodium tripolyphosphate 1.58 parts

[0035] d. Konjac flour 1.08 parts

[0036] Its preparation steps are as follows:

[0037] A. Dissolve sodium hydroxide in distilled water to make pH = 12; B. Take 100 parts of the step A solution, add sodium tripolyphosphate, and stir evenly; C. Add konjac powder to the step B solution, and stir at the same time to make it Disperse evenly; D, place it at room temperature for 8 hours to ensure that the konjac flour is fully swollen, and control the temperature at 18 or 20 or 22 or 25°C; E, heat up, heat it up to 60°C and keep it for 16 or 20 or 24 hours, and the resulting gel Soak and wash with distilled water 3 or 4 or 5 times to remove residual ions, and then dry in an oven at 45-60°C.

Embodiment 2

[0039] a. Sodium hydroxide 0.04 parts

[0040] b. Distilled water 100 parts

[0041] c. Sodium tripolyphosphate 0.31 parts

[0042] d. Konjac flour 2.16 parts

[0043] The preparation steps are the same as in Example 1.

Embodiment 3

[0045] a. Sodium hydroxide 0.0004 parts

[0046] b. Distilled water 100 parts

[0047] c. Sodium tripolyphosphate 6.31 parts

[0048] d. Konjac flour 2.16 parts

[0049] The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com