Method and system for operating a hydrocarbon production facility

A technology of hydrocarbons and facilities, applied in general control systems, control/regulation systems, computers used in chemical treatment processes, etc., can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

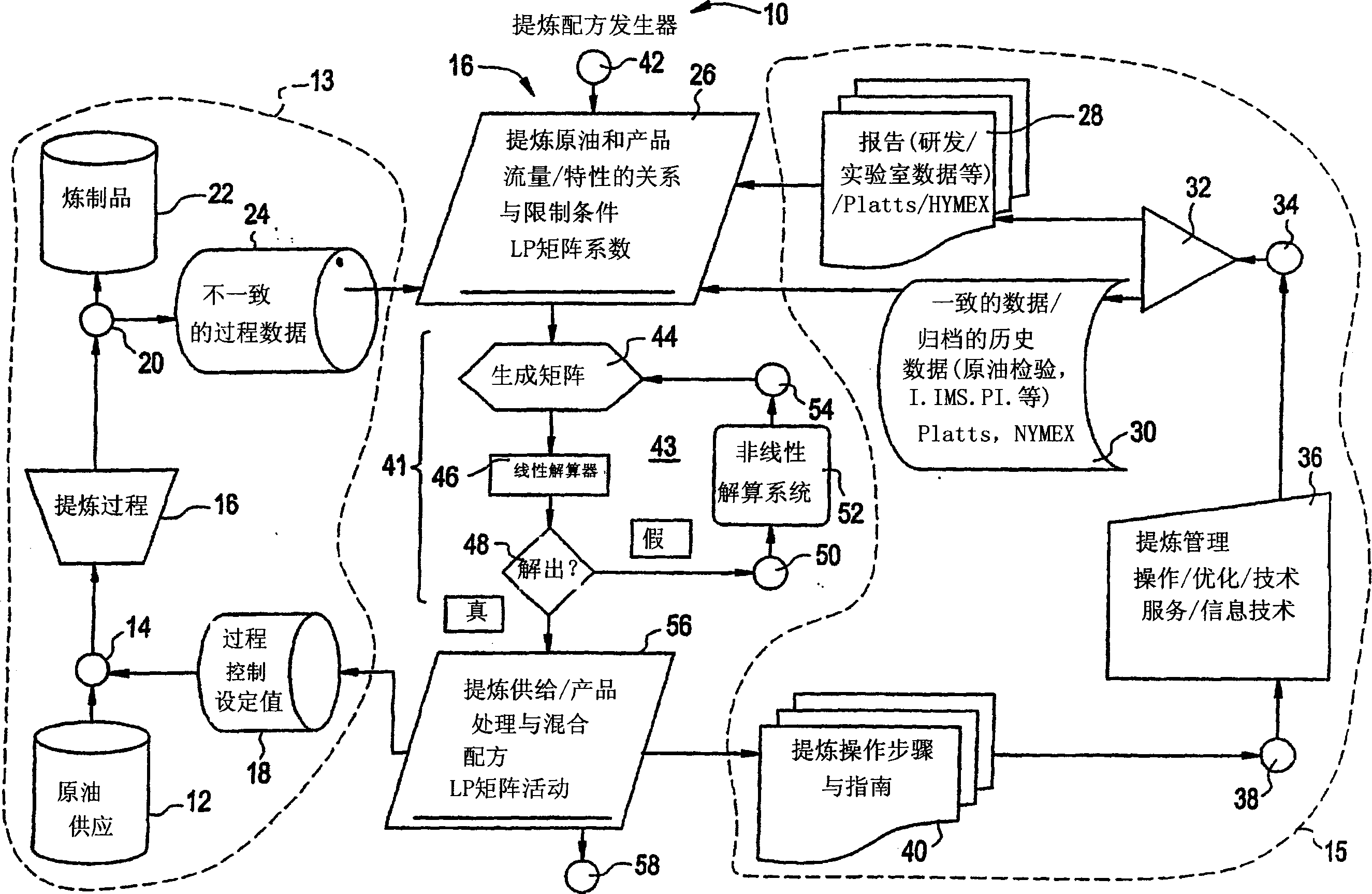

[0080] The following example is a small portion of the matrix for the aforementioned DEMEX unit. An extraction column is provided to receive the bottoms (heavies) from the vacuum column containing demetallized oil (DMD), resins and bitumen. Propane and butane are also available as extraction solvents. DMD and resin are collected from the top of the extraction column and passed to a flash drum to produce separated DMO and resin products. Bitumen is collected from the bottom of the extraction column. For this example, the dependent variable represents the product yield of the extraction column and the independent variable represents the temperature of the extraction column, so the combined activity of feed and production must be zero because of mass balance constraints. More specifically, the relationship that characterizes the extraction column yield is:

[0081] Yield (DMO) = a DMO ·T ext

[0082] Yield (resin) = a 树脂 ·T ext

[0083] Yield (asphalt) = a 沥青 ·T ext

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com