Support type universal drilling machine

A bracket type, drilling rig technology, applied in rotary drilling rigs, impact drilling, rotary drilling and other directions, can solve the problems of slow drilling speed, high labor intensity, low efficiency, etc., to improve drilling speed, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

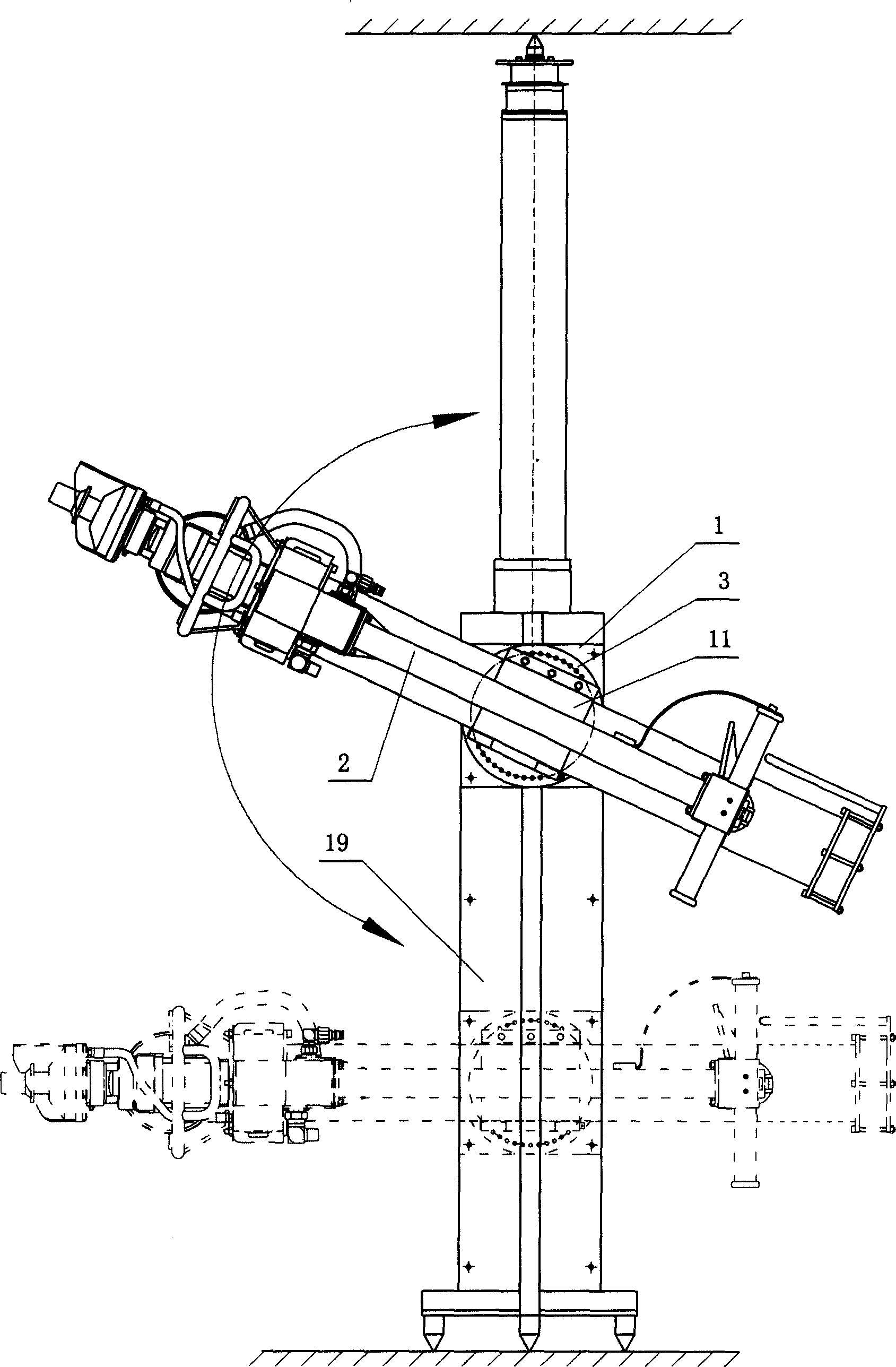

[0022] A bracket-type universal drilling machine includes a connecting device, a drilling machine 2 and a bracket 19.

[0023] Drilling rig 2 is a "piston rod propelling type rock bolter" with utility model patent application number 200520022875.8.

[0024] The support 19 is a "cylinder support type support" whose utility model patent application number is 200520022917.8.

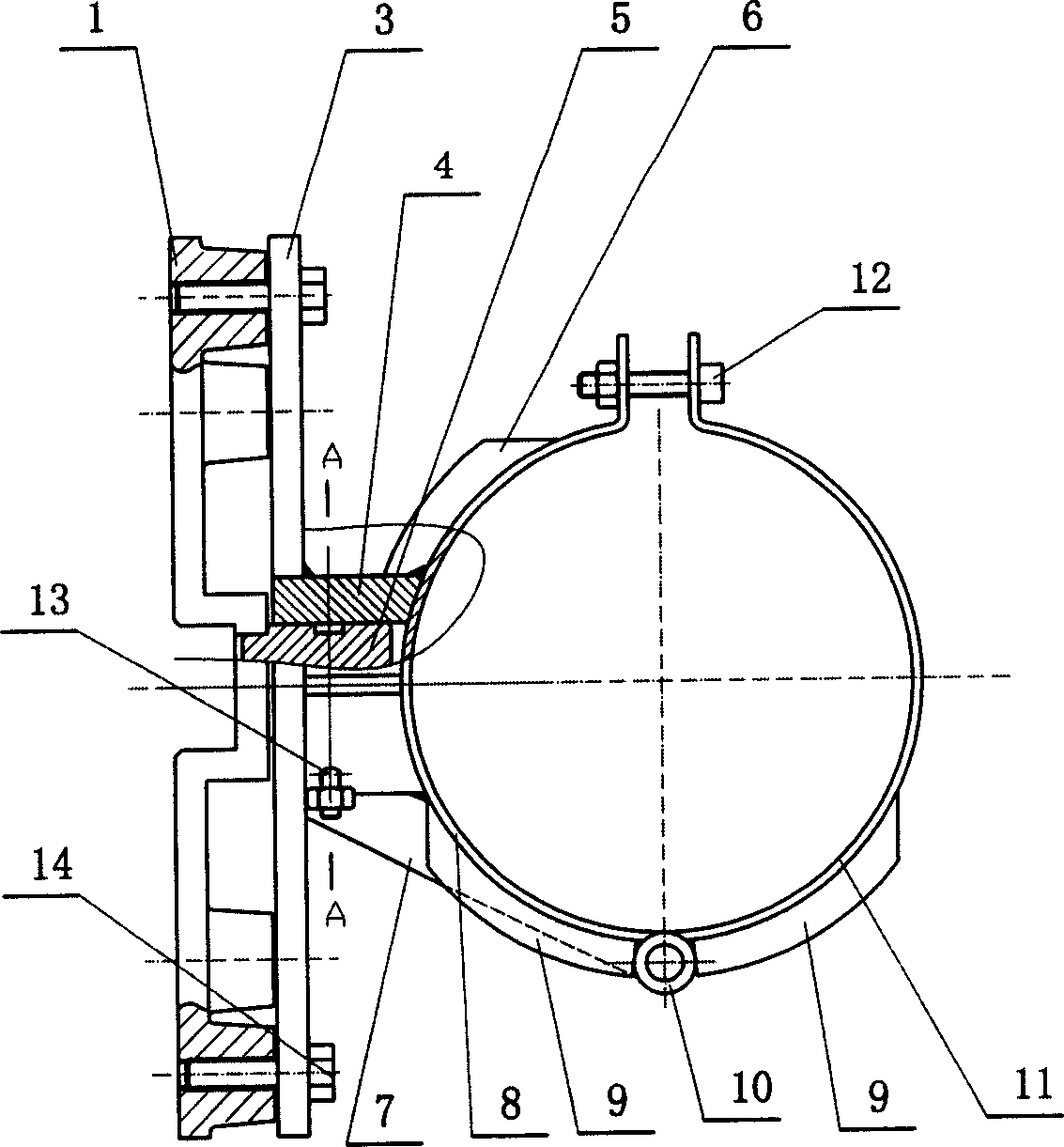

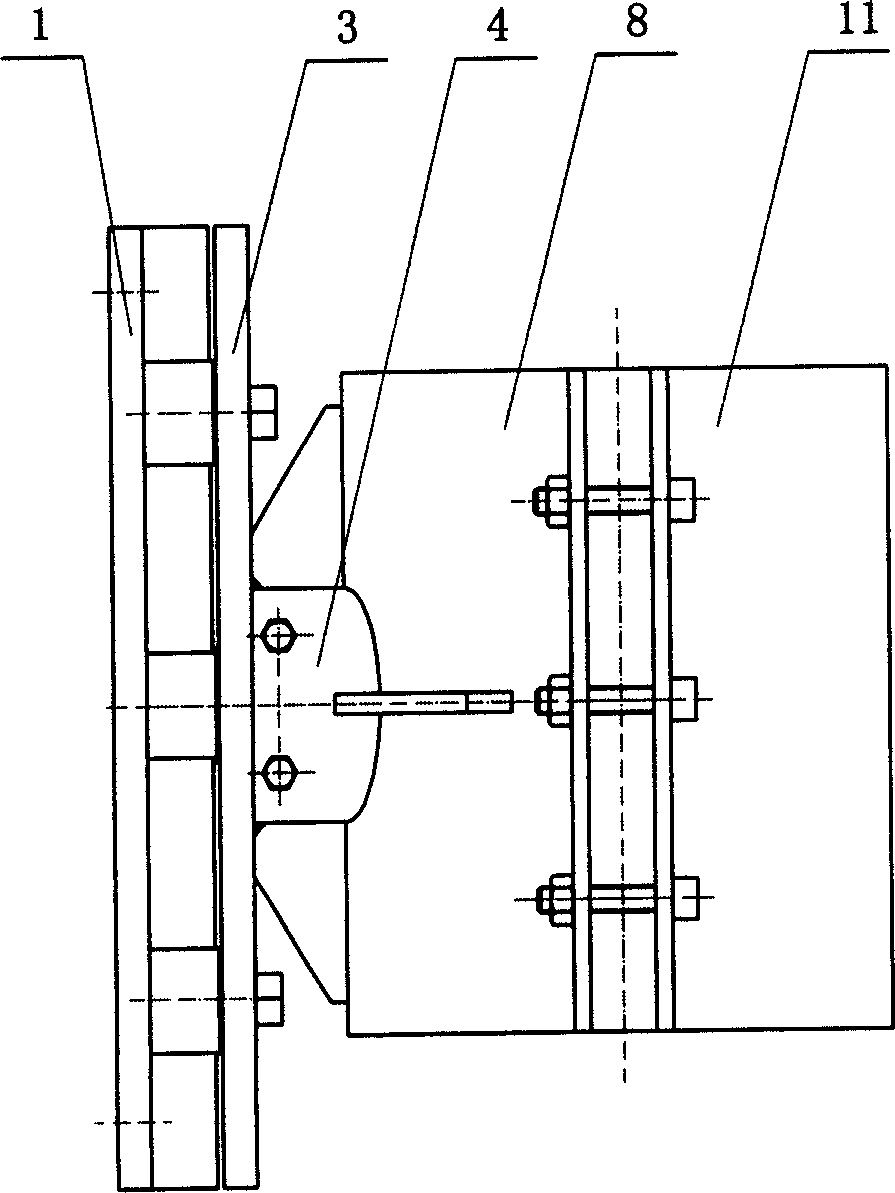

[0025] The connecting device consists of three parts: connecting parts, rotating parts and clamping parts.

[0026] The connection parts include: a connection bottom plate 1 and a rotation pin 5 .

[0027] Depend on figure 2 , Figure 4 and Figure 5 It can be seen that the connection base plate 1 is a convex structure, and one side of the connection base plate 1 is raised in the middle, and there is a rectangular groove in the middle of the other side. The depth and width of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com