Single-mode green light laser of semiconductor pumping

A technology of semiconductors and lasers, which is applied in the field of single-mode high-power frequency-doubling green lasers, can solve problems such as the application limitations of harmonic laser fine processing, and achieve the effect of balancing thermal lens effects and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

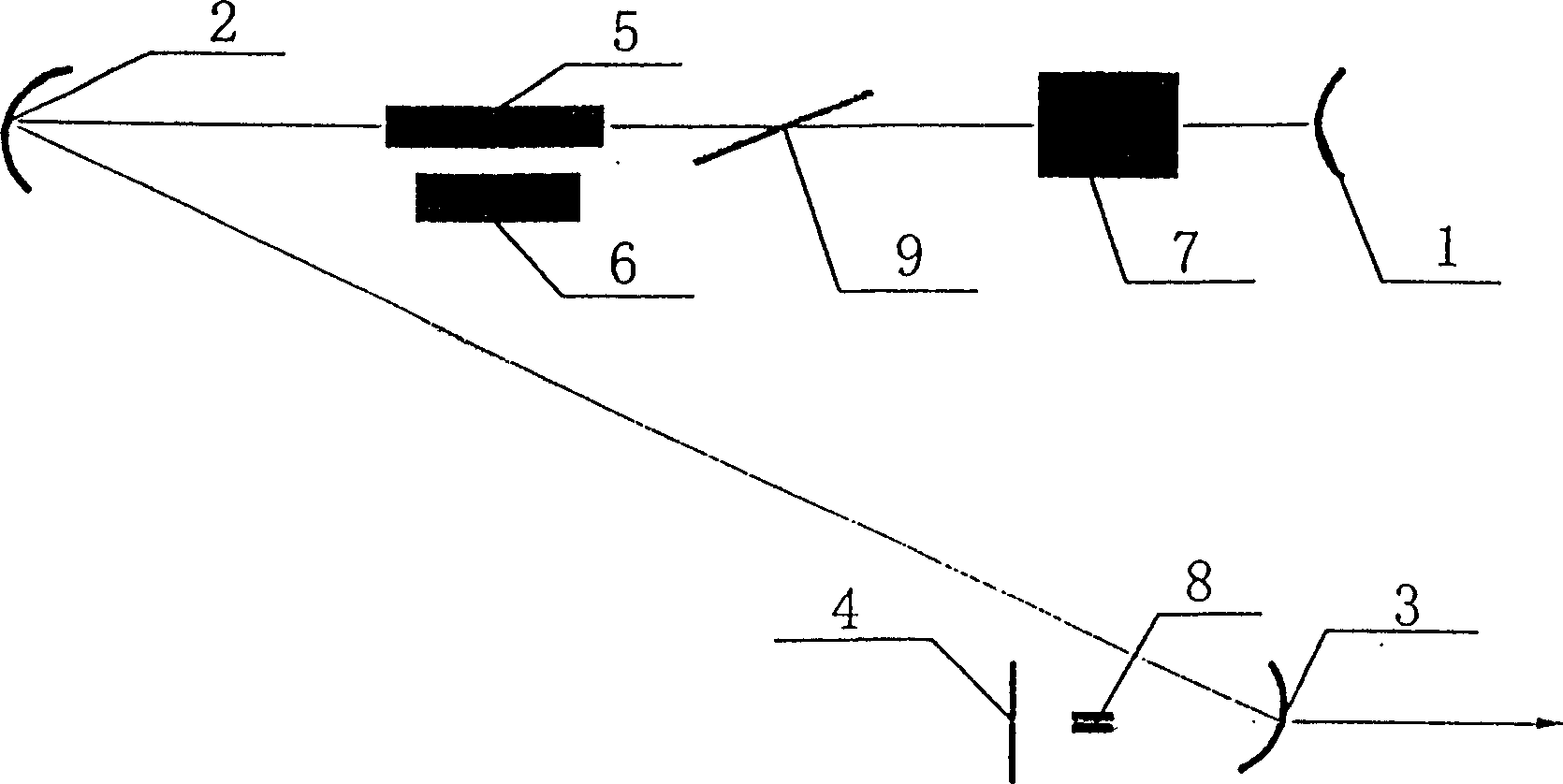

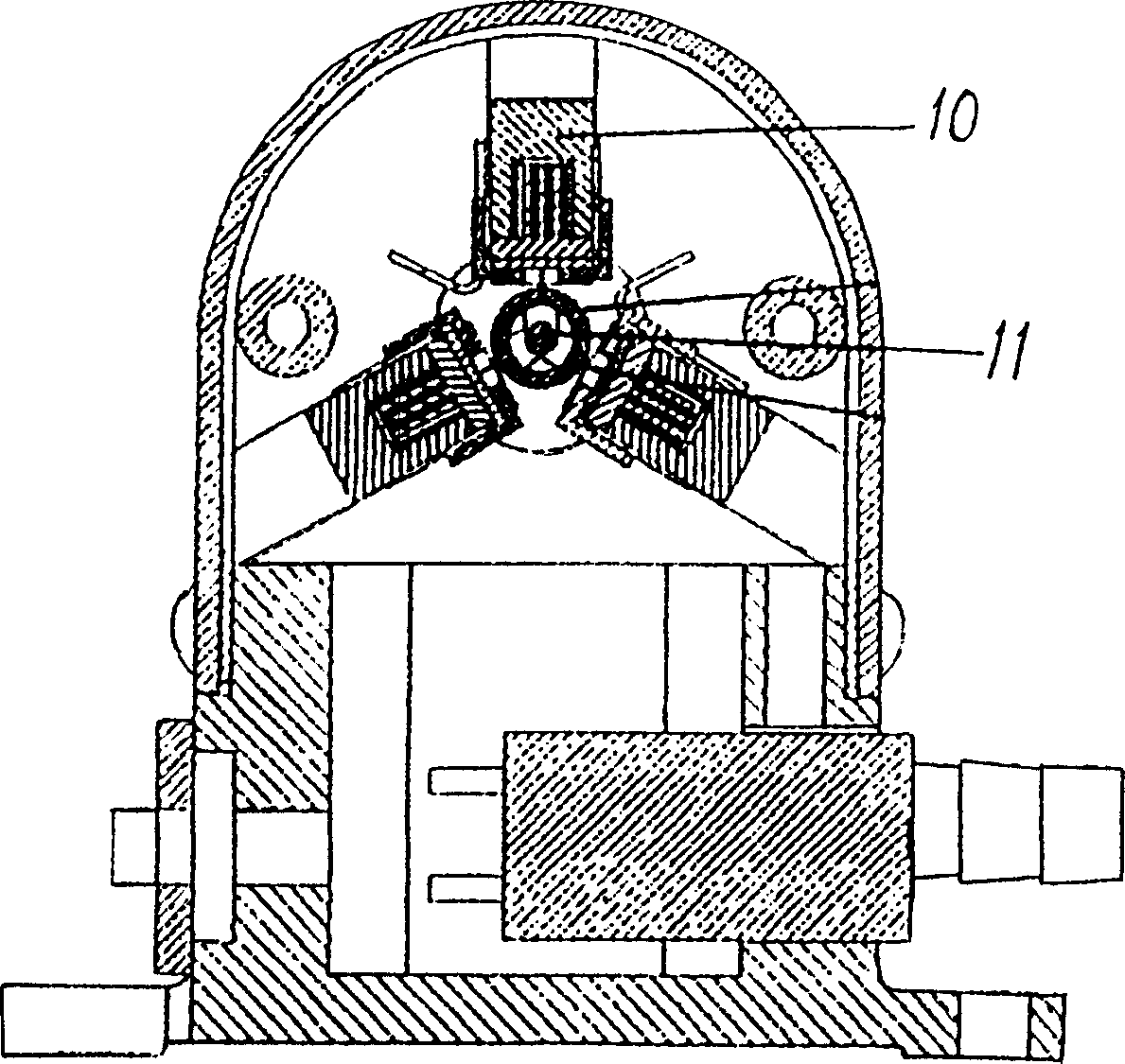

[0023] Below in conjunction with embodiment the optical path schematic diagram of the single-mode green laser of the semiconductor pump of the present invention is further described: by figure 1 It can be seen that the semiconductor-pumped single-mode green laser in this embodiment includes a solid-state laser medium 5, an optical pump 8 composed of a laser diode, and the like. The light pumping light sent from the laser diode is coupled to the laser medium 5, and the laser is stimulated and amplified in the device 6, the laser resonator composed of lenses 1-4, the Q-switching switch device 7 and the frequency doubling crystal resonator, and the resulting high Power density The fundamental wave in the cavity acts on the frequency-doubling crystal 8 to form a high-power and high-density frequency-doubling green laser output. Each component is described in further detail below:

[0024] The solid-state laser medium 5 used in this embodiment is a medium capable of generating las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com