Method for rinsing membrane-filtering unit of hollow fiber

A fiber membrane and hollow technology, which is applied in the flushing field of hollow fiber membrane filtration devices, can solve problems such as large water consumption, low cleaning efficiency, and limited cleaning effect, and achieve the goals of prolonging service life, improving flushing efficiency, and reducing flushing water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

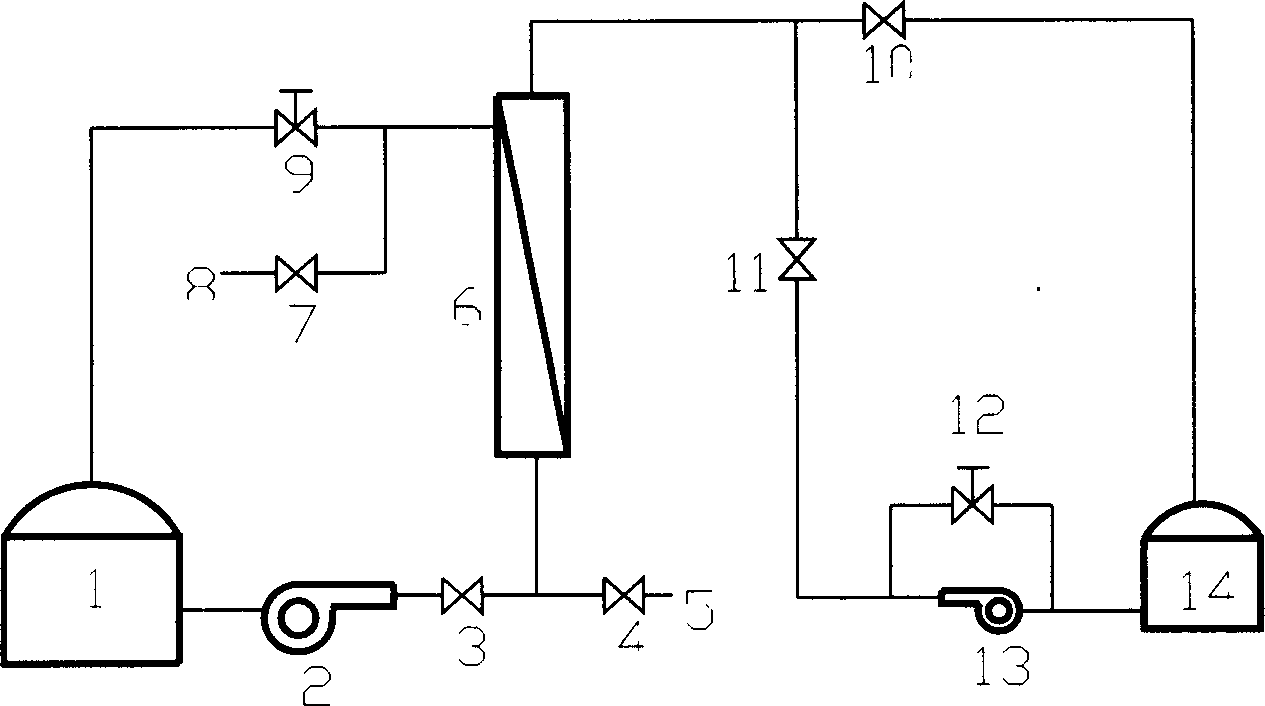

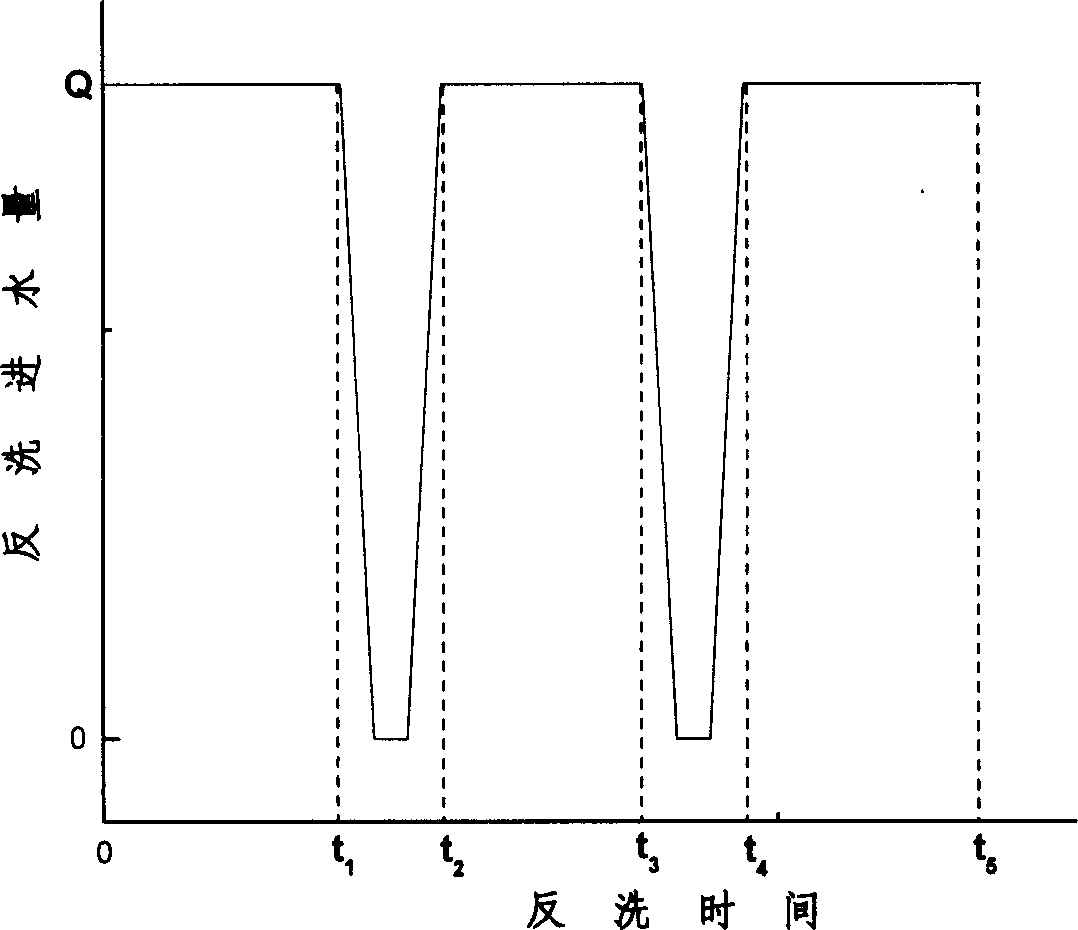

[0015] The invention provides a cleaning method for a hollow fiber membrane filter device. In a specific embodiment, the hollow fiber membrane module used is a four-inch polyvinylidene fluoride microfiltration membrane module, and the feed of the hollow fiber membrane filtration device is the sewage of the circulating cooling tower, after being treated by the microfiltration membrane device , can intercept most of the suspended solids, colloids, algae and other microorganisms in the wastewater, and the product water is clear and transparent and can be reused as reclaimed water. The backwash in the industrial wastewater treatment process adopts the pulse water supply scheme, such as figure 2 As shown, the backwashing water therein is the water produced by the microfiltration membrane device. The method for cleaning the membrane by using the pulse supply of flushing water in the present invention will be described in detail below.

[0016] After a certain period of operation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com