Foamed polyurethane mat containing charcoal, and its processing method

A production method, polyurethane technology, applied in the field of foamed polyurethane sheets, can solve the problems of inversion elasticity, activated carbon shedding, lowering, etc., and achieve the effect of preventing shedding and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

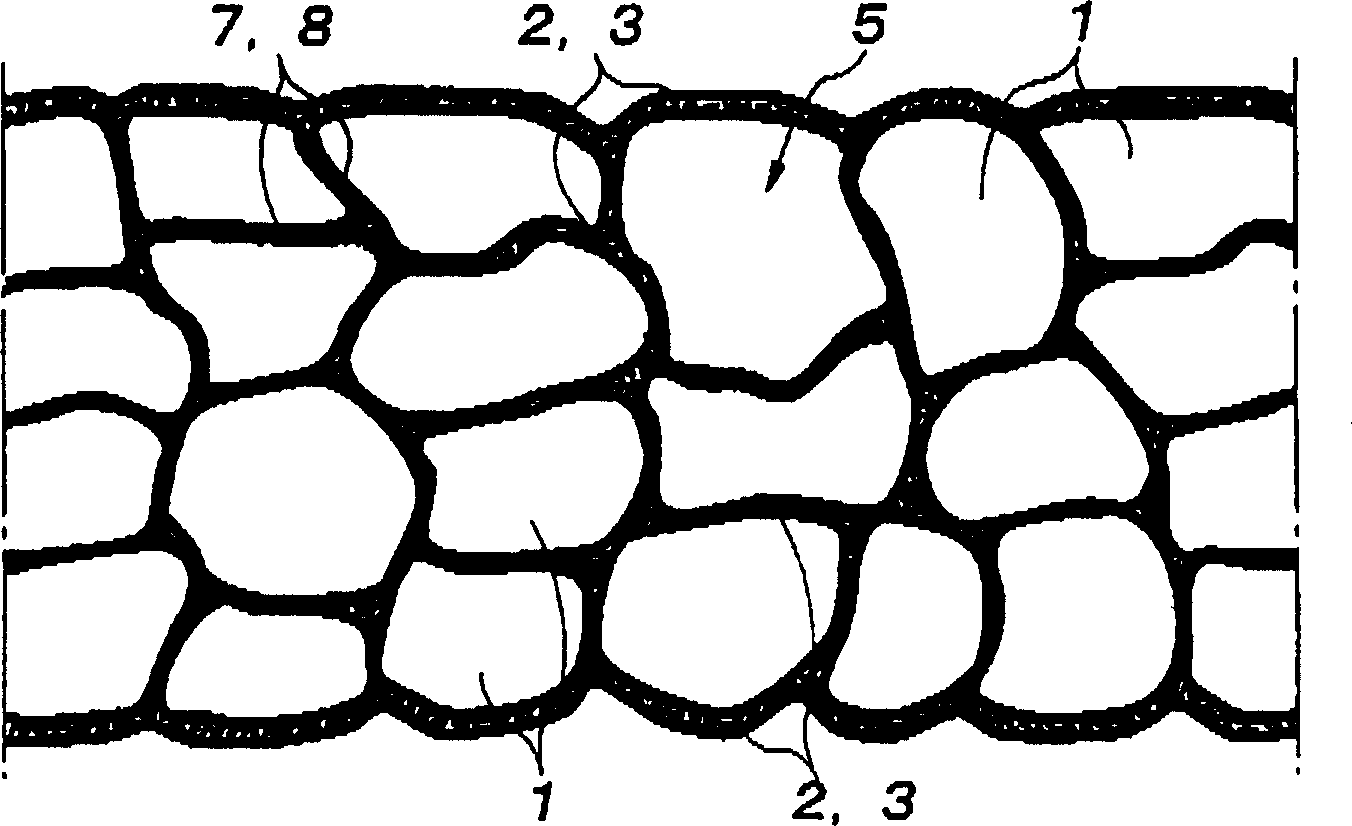

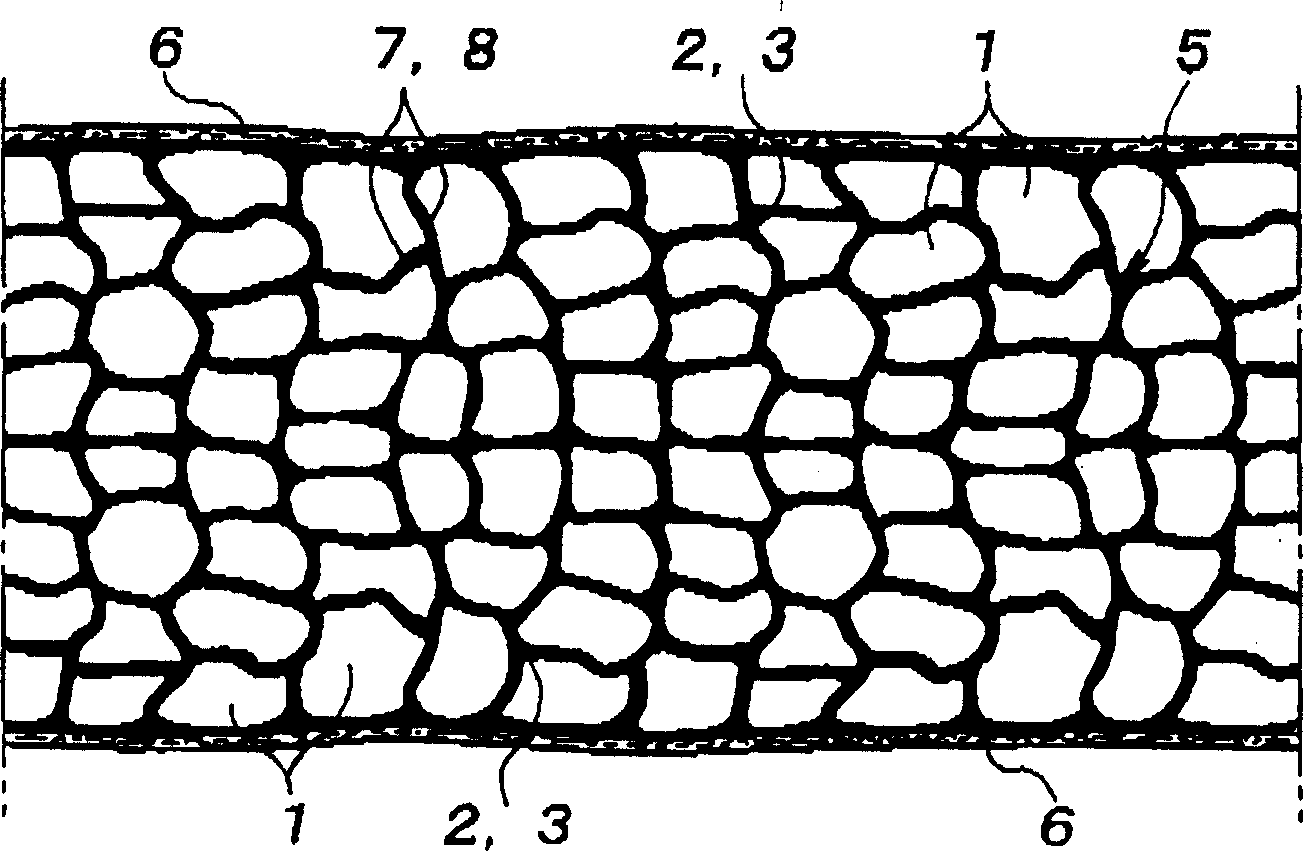

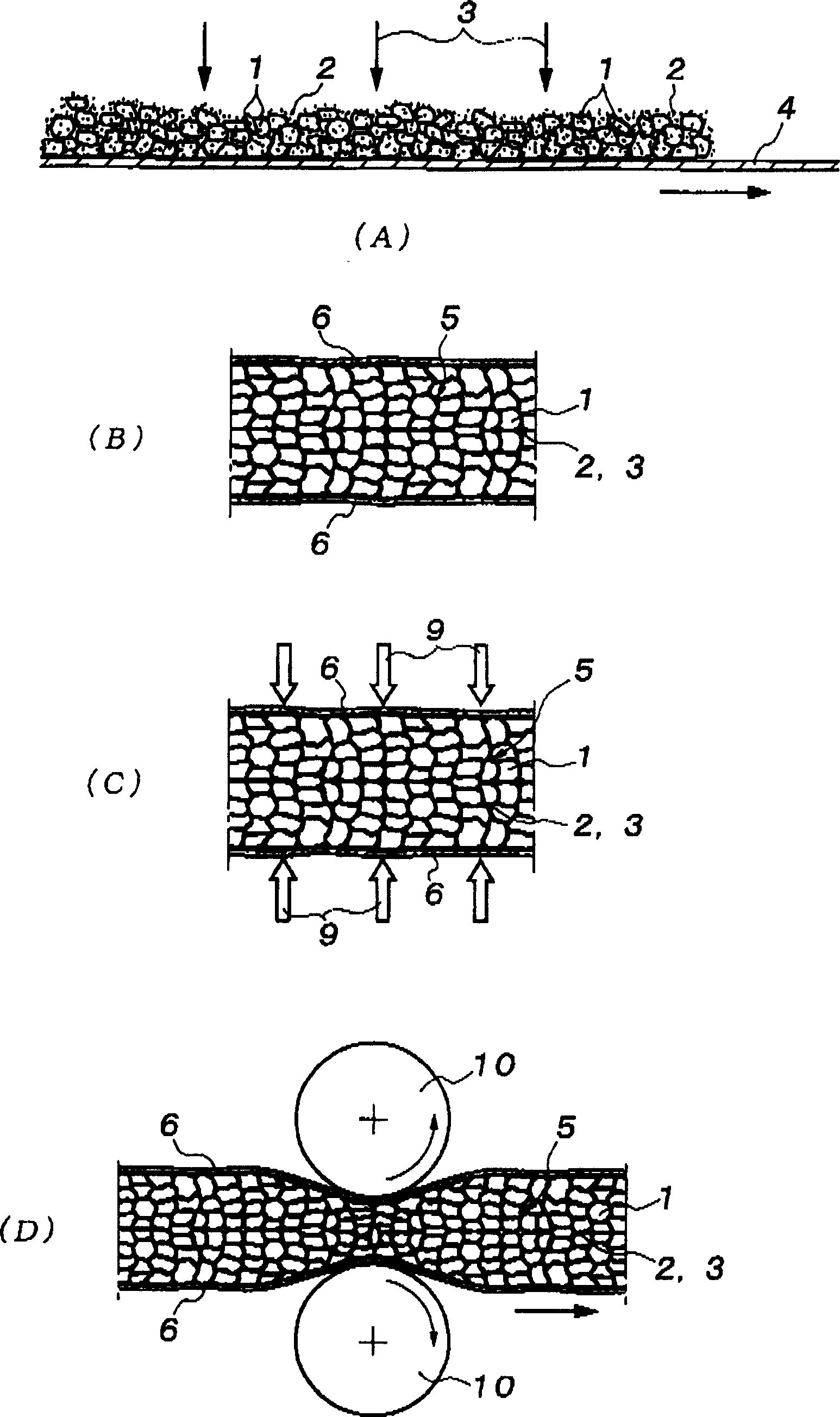

[0024] Shown in accompanying drawing, 1_foam polyurethane sheet, 2_carbon powder, 3_interlayer, 4_conveyor belt, 5_mixed material layer, 6_non-woven fabric, 7_rubber-like elastic layer, 8_carbon powder layer, 9 _ water vapor, 10_ pressure wheel, 11_ mesh conveyor belt.

[0025] Foamed polyurethane is widely used in products such as bedding and furniture, and most of them are flexible foamed polyurethane, which is suitable as an elastic material for these products.

[0026] And because a large amount of waste materials and defective products are produced in the factory of producing above-mentioned flexible polyurethane foam, the carbonized polyurethane foam pad of the present invention adopts waste foam polyurethane, especially waste flexible polyurethane foam as raw material.

[0027] The specific process is to put the above-mentioned flexible polyurethane foam into a crusher and crush into flexible polyurethane foam sheets of 10-30 mm size.

[0028] Add charcoal powder 2 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com