Extrusion molding method for curved generatrix hole

A bus hole and curve technology, which is applied in the field of processing curve bus holes, can solve the problems of high processing cost, low production efficiency, affecting excellent characteristics, etc., and achieve the effect of saving processing cost, low forming force and simple mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

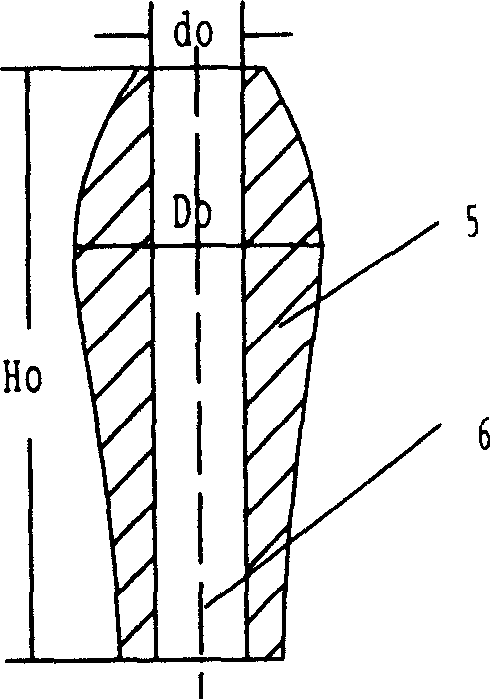

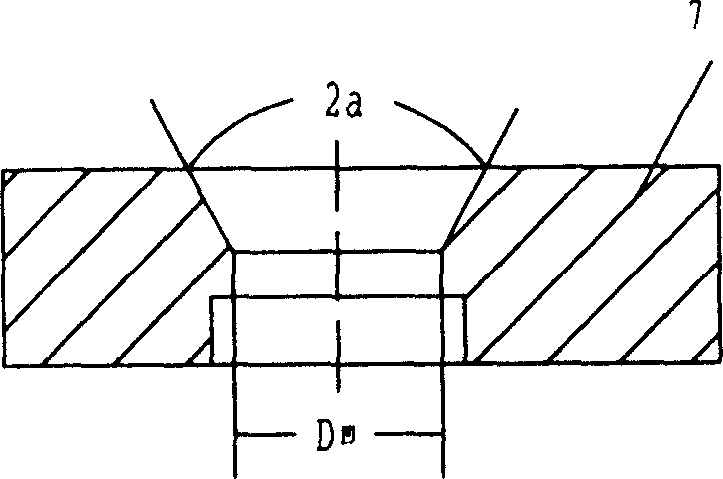

[0022] The open cold extrusion adopted in the present invention is a high-efficiency, energy-saving, and material-saving forming processing technology, which is generally suitable for shaft sleeve parts. Compared with the closed type, the open cold extrusion also has the advantages of simple molds, low forming force, Unique advantages such as energy saving and pollution-free. Open cold extrusion technology can produce busbar curve hole parts that cannot or are difficult to produce by traditional processing methods, such as various streamlined inner holes. These streamlined curves can be parabolic, hyperbolic, etc.

[0023] An example of this invention is the machining of Laval nozzles.

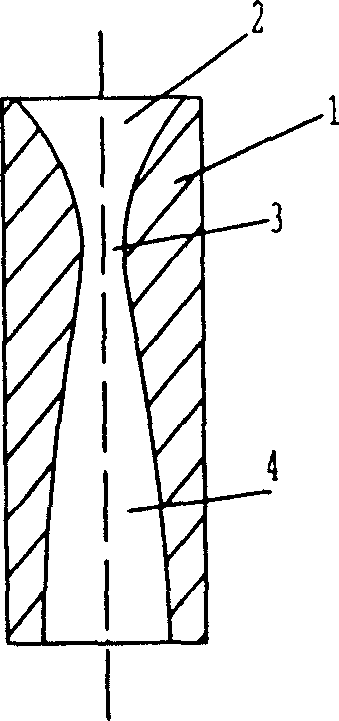

[0024] figure 1 is a cutaway view of the Laval nozzle. In the figure, Laval nozzle 1 is divided into three parts: contraction section 2, throat mouth 3, and expansion section 4. The cross-section of the pipe is a process of continuous change from large to small, and then from small to large....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com