Dedicated mortar for steaming and pressing fly ash brick and aerated concrete building block

A technology of autoclaved fly ash bricks and aerated concrete blocks, which is applied in the field of special mortar, and can solve problems such as plastering layer falling off, wall cracking, affecting the promotion of new wall materials and the quality of construction projects, and improving water retention Sexuality, solving cracks, and preventing wall leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention are described below:

[0011] Embodiments of the present invention include gypsum, Portland cement, fly ash, fly ash activator, water-retaining thickener, redispersible rubber powder, and crack-resistant fiber; the quantity ratio is 30% of gypsum, silicate 15% of cement, 45% of fly ash, 0.1% of water-retaining thickener, 2% of redispersible rubber powder, and 0.1% of crack-resistant fiber, of which the fly ash activator is 2% of the total amount of fly ash.

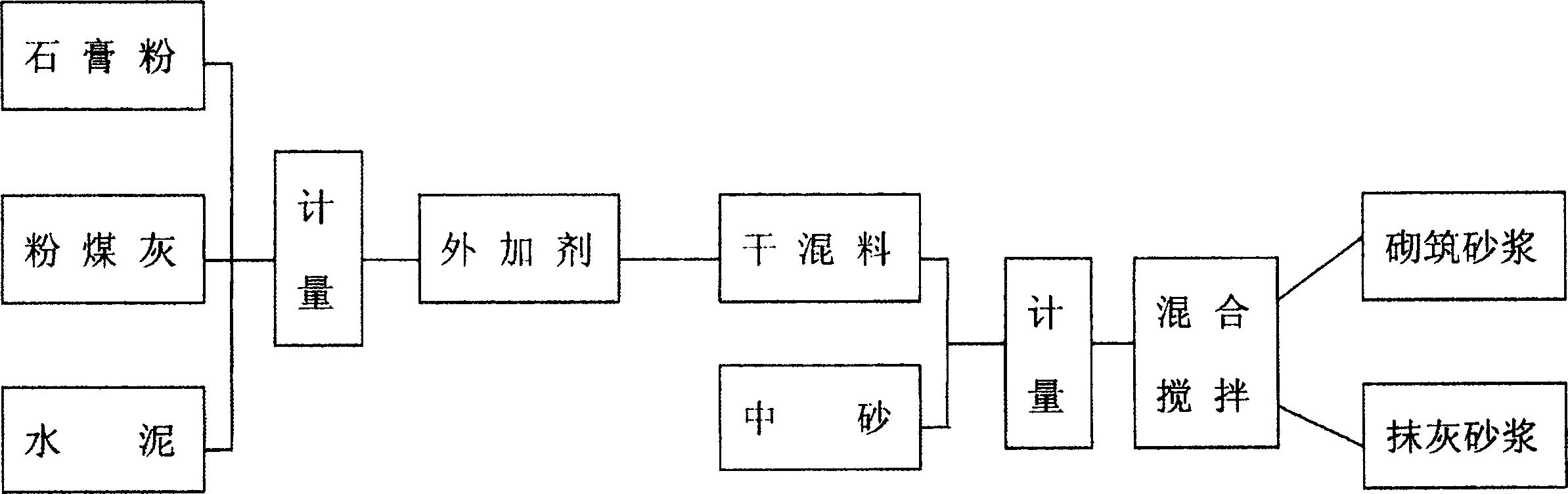

[0012] The production process is as follows: ① raw material preparation - prepare gypsum powder, fly ash, cement, powdery dry material; Agent--prepare the quantity of fly ash activator, water-retaining thickener, redispersible rubber powder, and crack-resistant fiber according to the ratio requirements; ④ dry mix--the prepared gypsum powder, fly ash, cement, Fly ash activator, water-retaining thickener, redispersible rubber powder, and crack-resistant fiber are sent to the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com