Heat processing unit case heat treating method and its device

A technology of local heat treatment and induction heating device, applied in heat treatment furnaces, heat treatment equipment, induction heating devices, etc., can solve problems such as large temperature difference, and achieve the effect of improving quality, productivity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

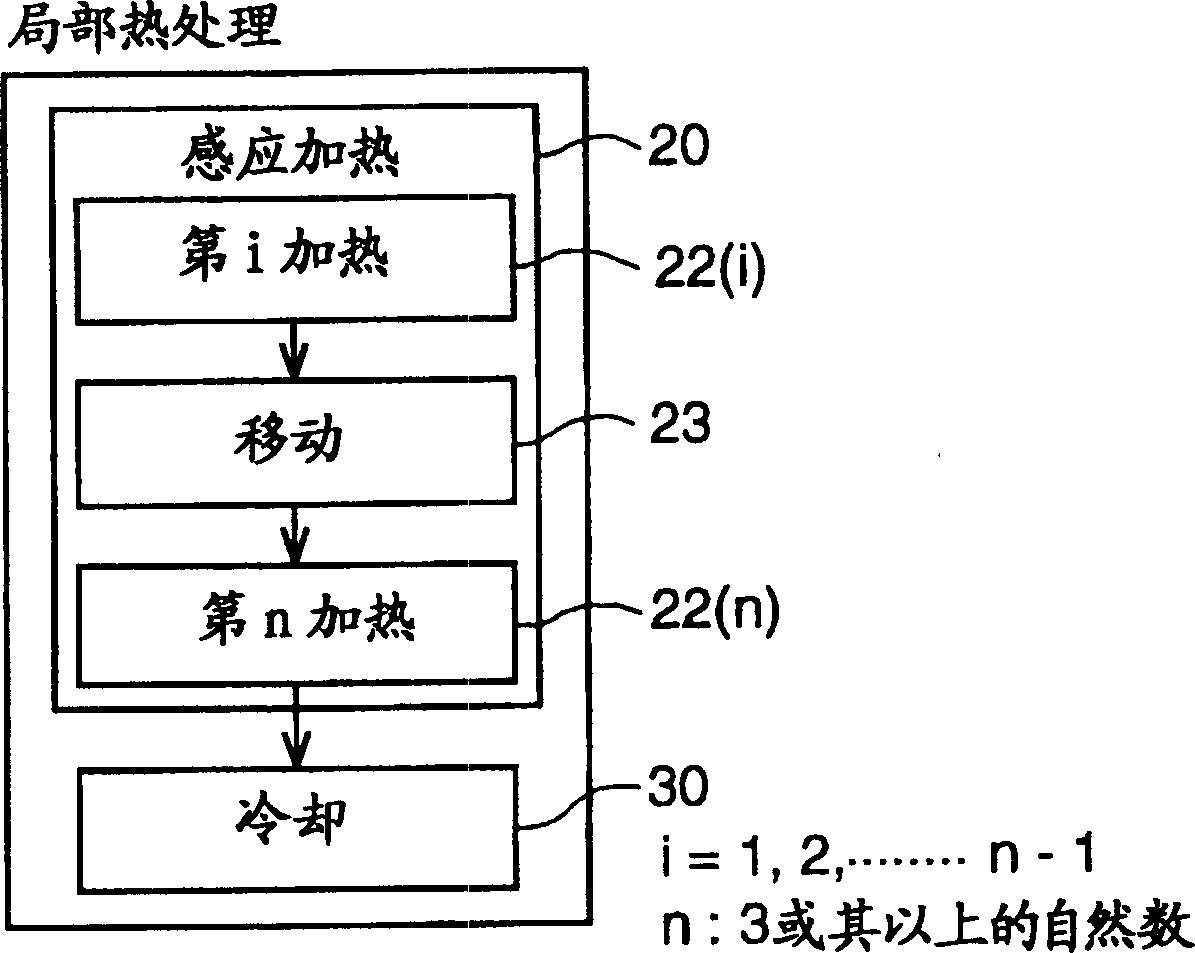

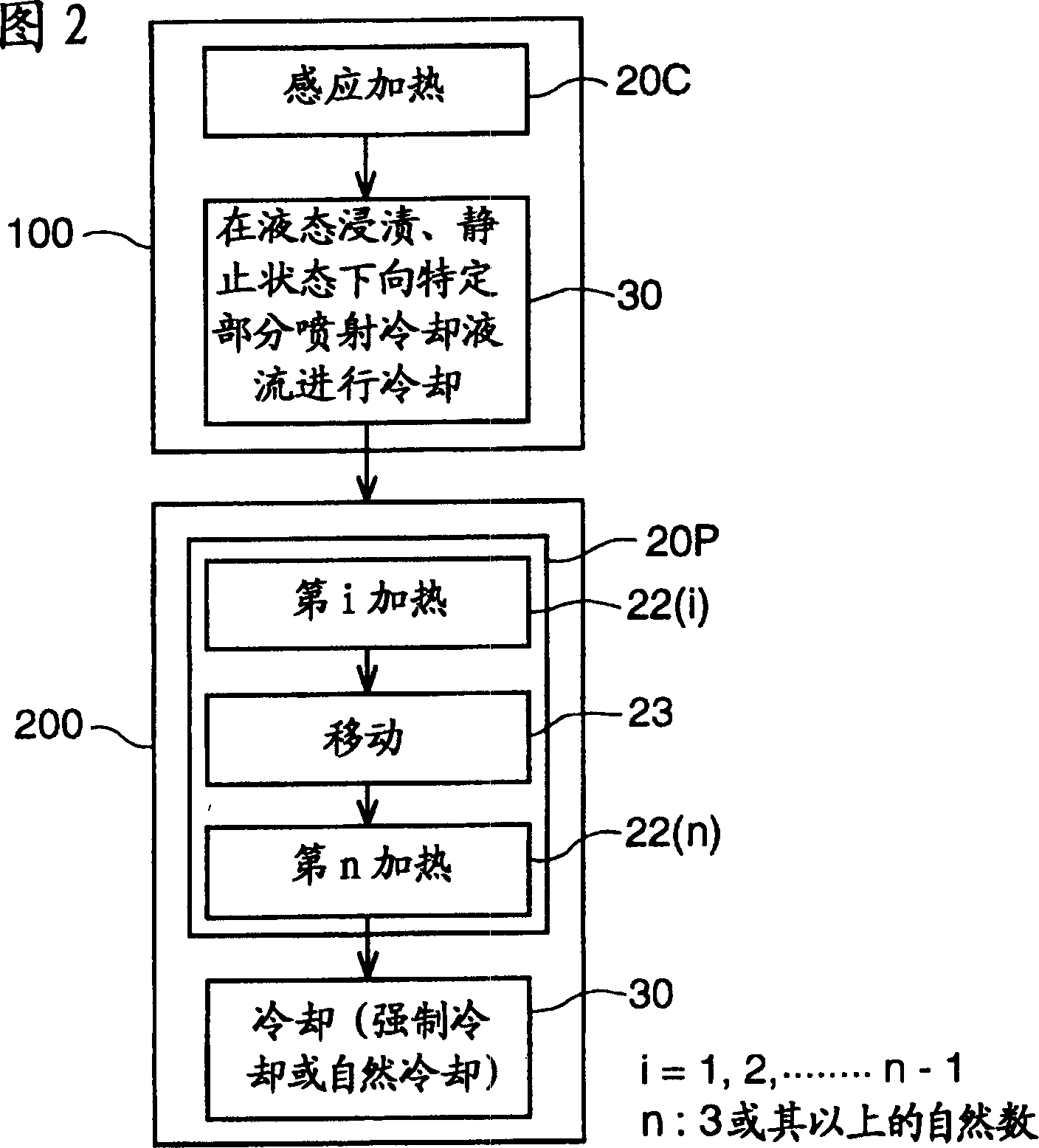

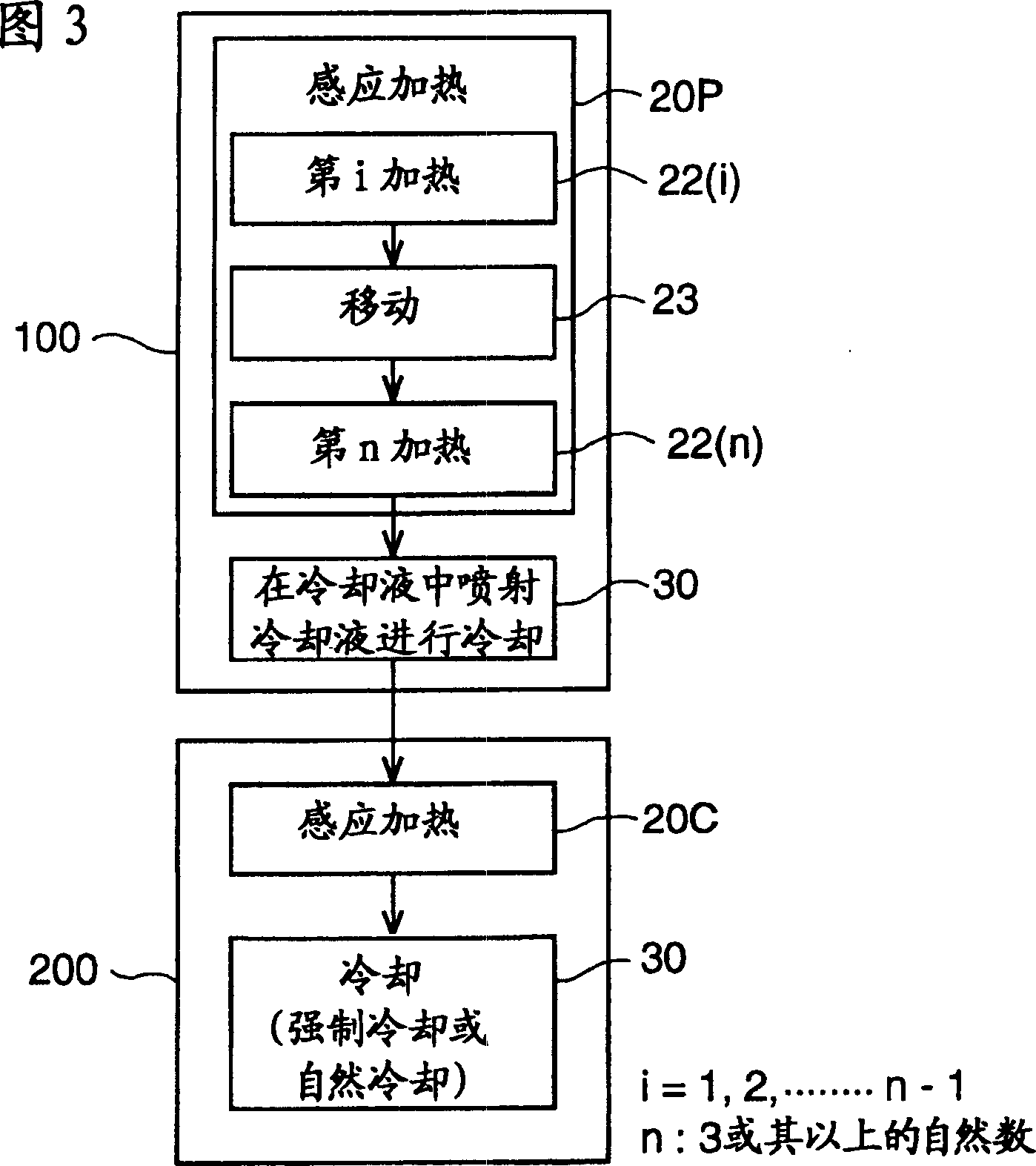

[0078] Below, refer to Figure 1 to Figure 6 and Figure 9~ Figure 14 (Figure 12~ Figure 14 (Description applicable to the prior art) The method and apparatus for local heat treatment of heat-treated components according to the present invention will be described.

[0079] As a heat-treated part, take a construction machinery crawler link as an example. However, the heat-treated components are not limited to the links for crawlers of construction machines. In addition, when the heat-treated component 1 is a track link 1 of a construction machine, the specific portion 1a to be heat-treated is a roller rolling surface.

[0080] First, the local heat treatment method of a heat-treated component according to the present invention will be described.

[0081] Such as figure 1 As shown, the local heat treatment method of the heat treatment component of the present invention is a local heat treatment method for heat treating only the specific portion 1a of the heat treatment comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com