Sterilizing and deodorizing method for paper making water and slime pulp controlling agent used thereby

A technology of control agent and aqueous solution, which is applied in the direction of adding slurry control agent, water treatment parameter control, papermaking, etc., and can solve the problems of ineffective tolerance, no prediction, and deterioration of the surrounding environment of the factory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

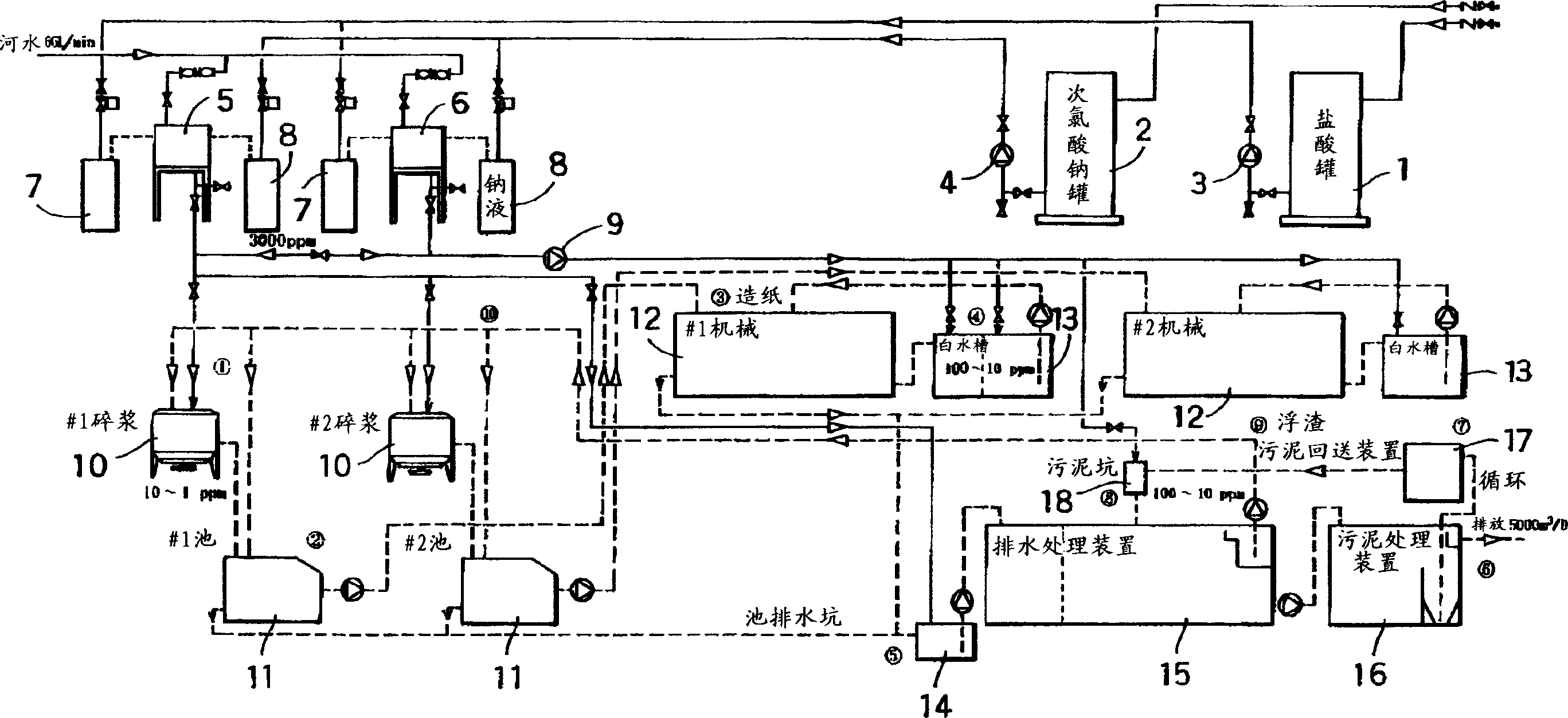

[0021] figure 1 It is HSP Co., Ltd.'s sodium hypochlorite aqueous solution manufacturing device Stery Mixer, which can mix 9% dilute hydrochloric acid and 12% sodium hypochlorite aqueous solution, and dilute it with water until the pH is in the range of 5 to 7, the concentration of available chlorine It is 3000±1000ppm, and it can be diluted 30-100 times with tap water. When using the above-mentioned dilute hydrochloric acid aqueous solution and sodium hypochlorite aqueous solution to adjust the above-mentioned aqueous solution, it is necessary to pay attention to avoiding the generation of chlorine gas due to excessively lowering the pH when adding hydrochloric acid. Therefore, it is preferable to use a pH regulator as needed before and after adding hydrochloric acid, especially potassium bicarbonate or sodium salt allowed for food addition, especially a solution containing 1-10%, to adjust the prescribed high available chlorine concentration while adjusting the pH of aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com