Enhanced lube oil yield by low hydrogen pressure catalytic dewaxing of paraffin wax

A technology for catalytic dewaxing and dewaxing, which is used in the petroleum industry, molecular sieve catalysts, hydrocarbon oil treatment products, etc., and can solve problems such as temperature increase and no mention of catalyst life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The technique for the preparation of molecular sieves is well known and is described, for example, in J. Schlenker, et al., Zeolites 1985, vol. 5, November, 355-358.

[0024] ZSM-48 was characterized by X-ray diffraction, see Table 1 below. The fact that it shows a single peak in the range of 11.8 ± 0.2 Å further confirms this material. The presence of a single peak in the region shown structurally distinguishes ZSM-48 from closely related materials such as ZSM-12, which has two lines in the range of 11.8 ± 0.2 Å, a doublet (U.S. Patent 3,832,449 It is described in), and high-silicon ZSM-12 also has double peaks in the display range (also described in U.S. Patent U.S. 4,104,294).

[0025] D()

Relative Intensity (I / Io)

11.8±0.2

S

10.2±0.2

W-M

7.2±0.15

W

4.2±0.08

vs.

3.9±0.08

vs.

3.6±0.06

W

3.1±0.05

W

2.85±0.05

W

[0026] These values ...

example 1

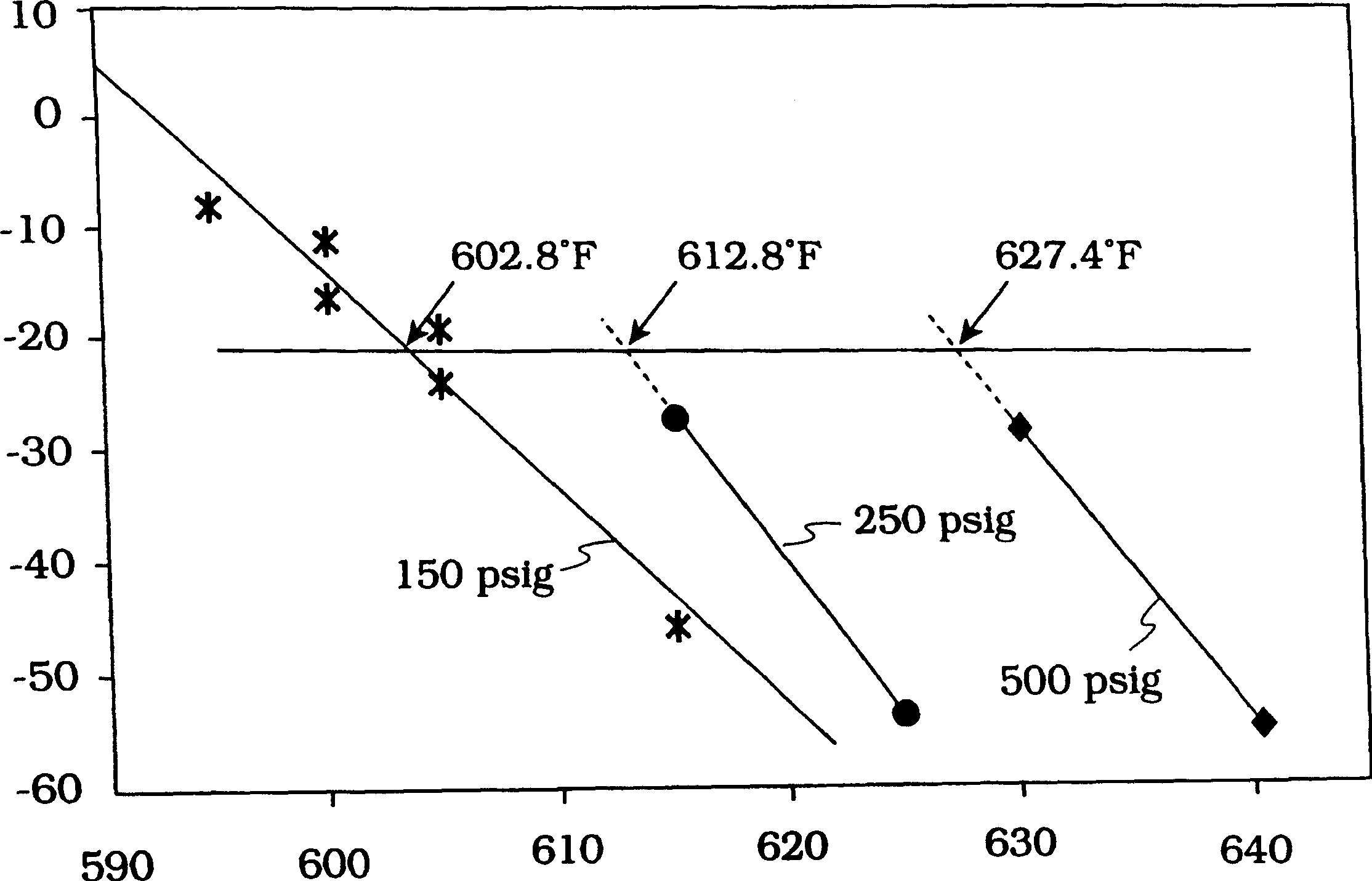

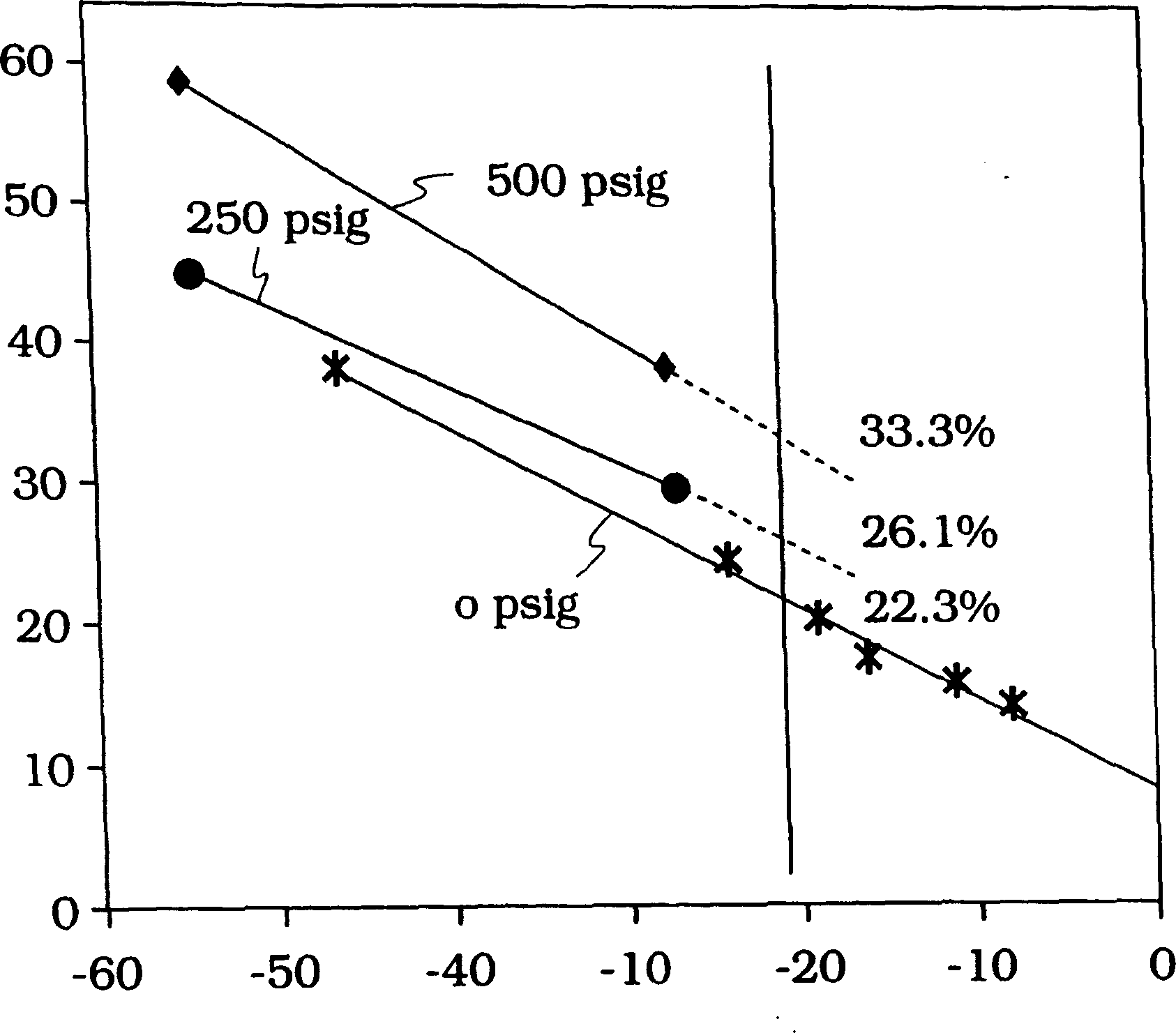

[0050] This example shows an advantage in lube base oil yield when the hydrogen partial pressure is reduced from 3549 kPa to 1136 kPa (500 psig to 150 psig). The following plant conditions and process parameters were investigated using a ZSM-48 using a broad cut Fischer-Tropsch feedstock, ie, a 221°C+ (430°F+) feedstock.

[0051] The catalytic dewaxing reaction was carried out in a downflow reactor, simulating a trickle bed reactor, submerged in a sand bath to maintain isothermal reactor conditions. The reactor was charged with 80 cc of unsulfurized ZSM-48 catalyst containing 35% alumina and 0.6 wt% platinum based on the total catalyst weight and diluted with glass beads. Cobalt slurry catalyzed Fischer-Tropsch process for waxes above 221°C+ (430°F+), whose conversion is controlled by temperature.

[0052] The process operates at a temperature of 304-338°C (580-640°F) and a reactor hydrogen partial pressure of 1136-3549 kPa (150-500 psig) at the reactor outlet. The hydrogen ...

example 2

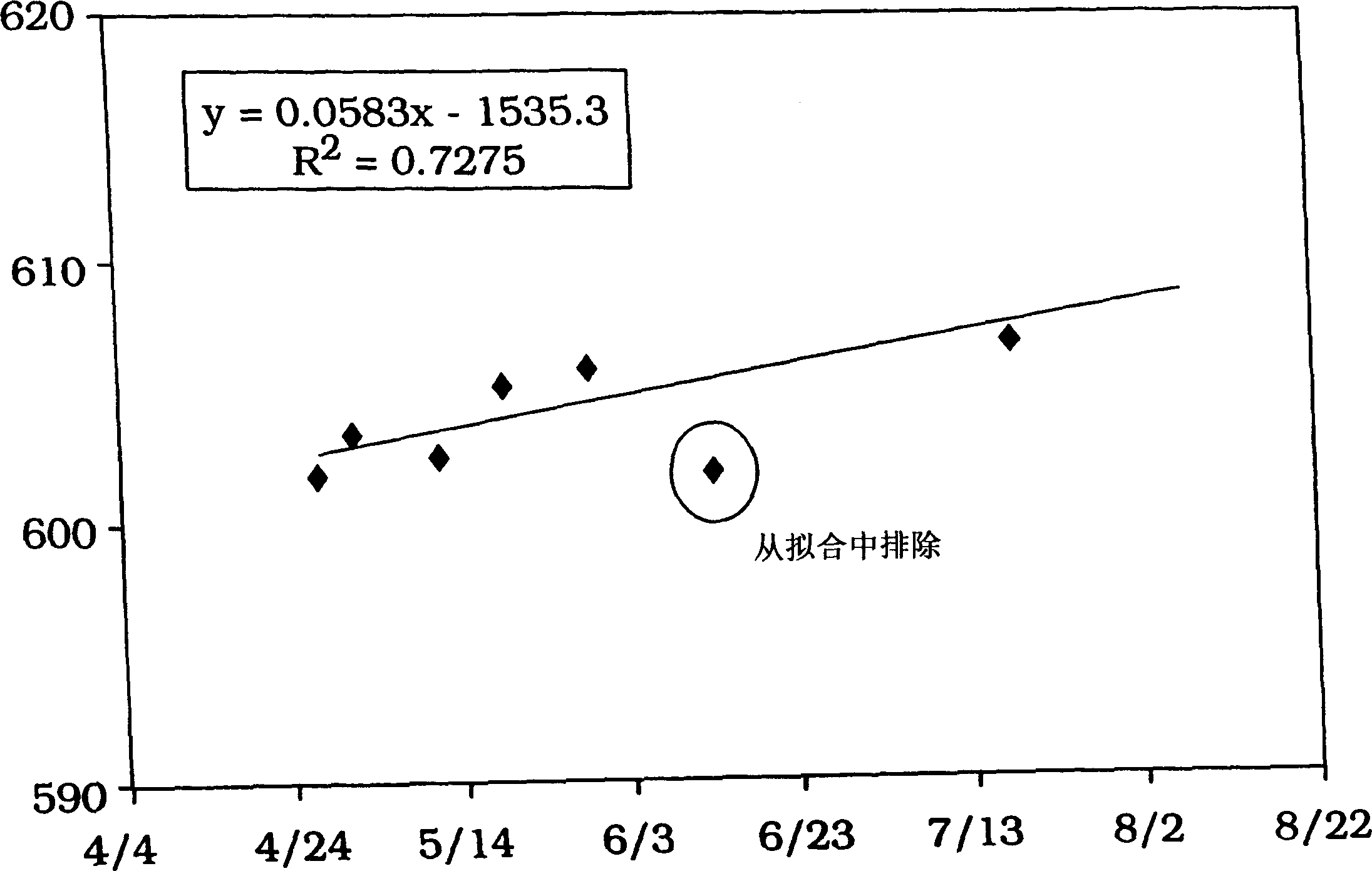

[0063] Using the reactor described in Example 1, the operation of a dewaxing unit at 1825 kPa (250 psig) was studied using a 221°C+ (430°F+) broad cut Fischer-Tropsch wax feedstock. Also using the catalyst of Example 1, the hydrogen treat gas was 445.3 liters (2500 SCF / bbl) at standard conditions (101.325 kPa and 15.5° C.) per liter of feedstock. The liquid hourly space velocity is 1.0. Adjust temperature to meet lube oil pour point or diesel cloud point requirements. When operating to meet the diesel cloud point requirement of -15°C, the deactivation rate is less than 1K / year (1.8°F / year). see results Figure 4 .

[0064] The deactivation rate is about 3K / year (5.4°F / year) when the unit is operated to meet the pour point requirement of a wide cut lubricating oil of -21°C. see results Figure 5 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap