Artificial skiing field

An artificial snow and man-made technology, applied in the direction of roads, other chemical processes, pavement, etc., can solve the problems of high sliding resistance, high cost, and the physical and chemical properties of natural snowfields are far from each other, and achieve the effect of low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

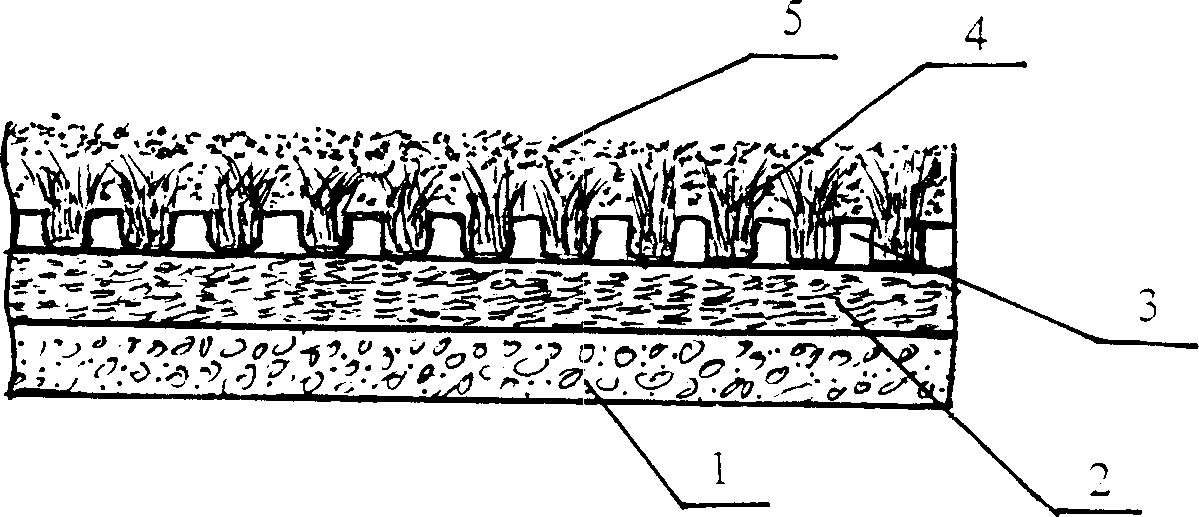

[0022] On the plane where concrete is used as the base layer 1, the elastic spongy polyurethane is bonded on the concrete plane with an adhesive to form an elastic layer 2. After drying, the high-strength hot-melt polyurethane is made of a layer with a height of 20 mm. The bottom plate of the columnar molded body with a diameter of 4 mm and a column distance of 5 mm is bonded to the elastic layer 2 to form a skeleton 3. Between the columns of the skeleton 3, a mixture of polyethylene and polypropylene plastics is inserted vertically at a ratio of 1:1. The formed snow-retaining stable fiber 4, the lower part of the fiber is bound on the perforated skeleton 3 bottom plate, and the artificial snow with a particle size of 1 mm made of polyethylene plus paraffin is sprinkled on the snow-preserving stabilizer supported by the skeleton 3. On the fiber layer 4, the surface layer of the ski resort is formed, which can be used by people as a ski resort.

Embodiment 2

[0024] Use polyvinyl chloride board as the base layer 1, fix the foamed PVC to form the elastic layer 2 by means of binding on the base layer 1, and then bond the skeleton base plate with a columnar molded body made of polyurethane to the elastic layer 2 Become skeleton 3 on top, and its cylinder height is 50 millimeters, and diameter is 8 millimeters and column distance is 15 millimeters, then vertically inserts the snow-preserving stable fiber 4 that is made of polyethylene between the columns of skeleton 3, and the bottom of its fiber binds On the perforated frame 3 bottom plate, the artificial snow made by the mixture of polyurethane and calcium stearate with a particle size of 2 mm is sprinkled on the snow-retaining stable fiber layer 4 supported by the frame 3 to form a snow-preserving stable fiber layer for people. As a surface layer for ski resorts.

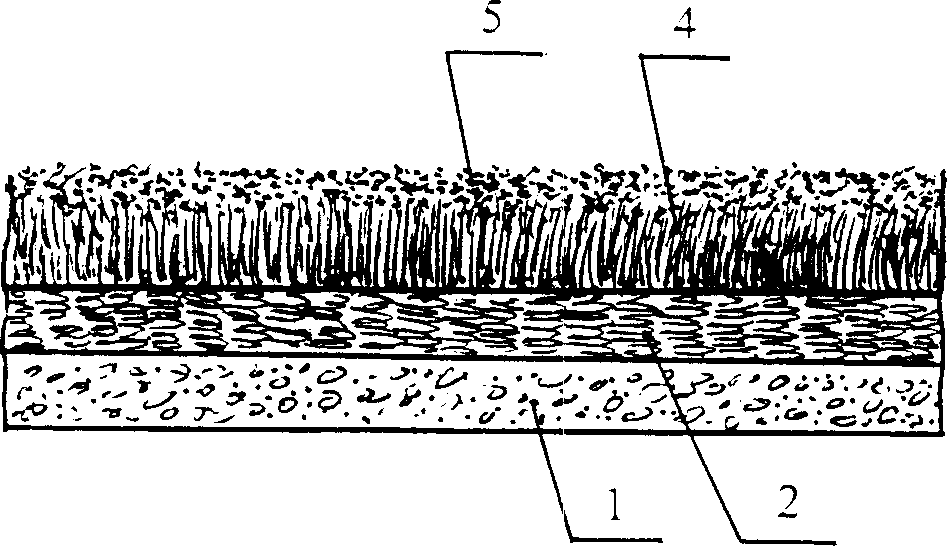

[0025] like figure 2 As shown, the artificial ski ground of the present invention is made of the base layer 1, the el...

Embodiment 3

[0027] On the plane where concrete is used as the base layer 1, an elastic spongy polyurethane is bonded on the base layer 1 with an adhesive to form an elastic layer 2. After drying, polyethylene and polypropylene are mixed in a ratio of 1:1. The snow-preserving stable fiber 4 made by mixing is vertically fixed on the elastic layer 2 by hot melting, and the density of its fiber is like grass, and then sprinkled on the fiber layer 4 with a particle size of 0.2 mm. Paraffin-waxed polypropylene artificial snow, which forms the surface of the ski area.

[0028] In the above-mentioned embodiments, if the base layer 1 is made of concrete or asphalt concrete, it should be implemented on site. If other materials are used, it can be fabricated and assembled in the workshop in advance, and then laid on site.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com