Method for building road isolation green belt guard-rail using waste tyres

A technology of waste tires and green belts, applied in roads, roads, road safety devices, etc., can solve the problems of high vehicle losses and casualties, lack of performance and quality of reclaimed rubber, high cost of promotion and utilization, etc., to beautify the road environment, Simple construction and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

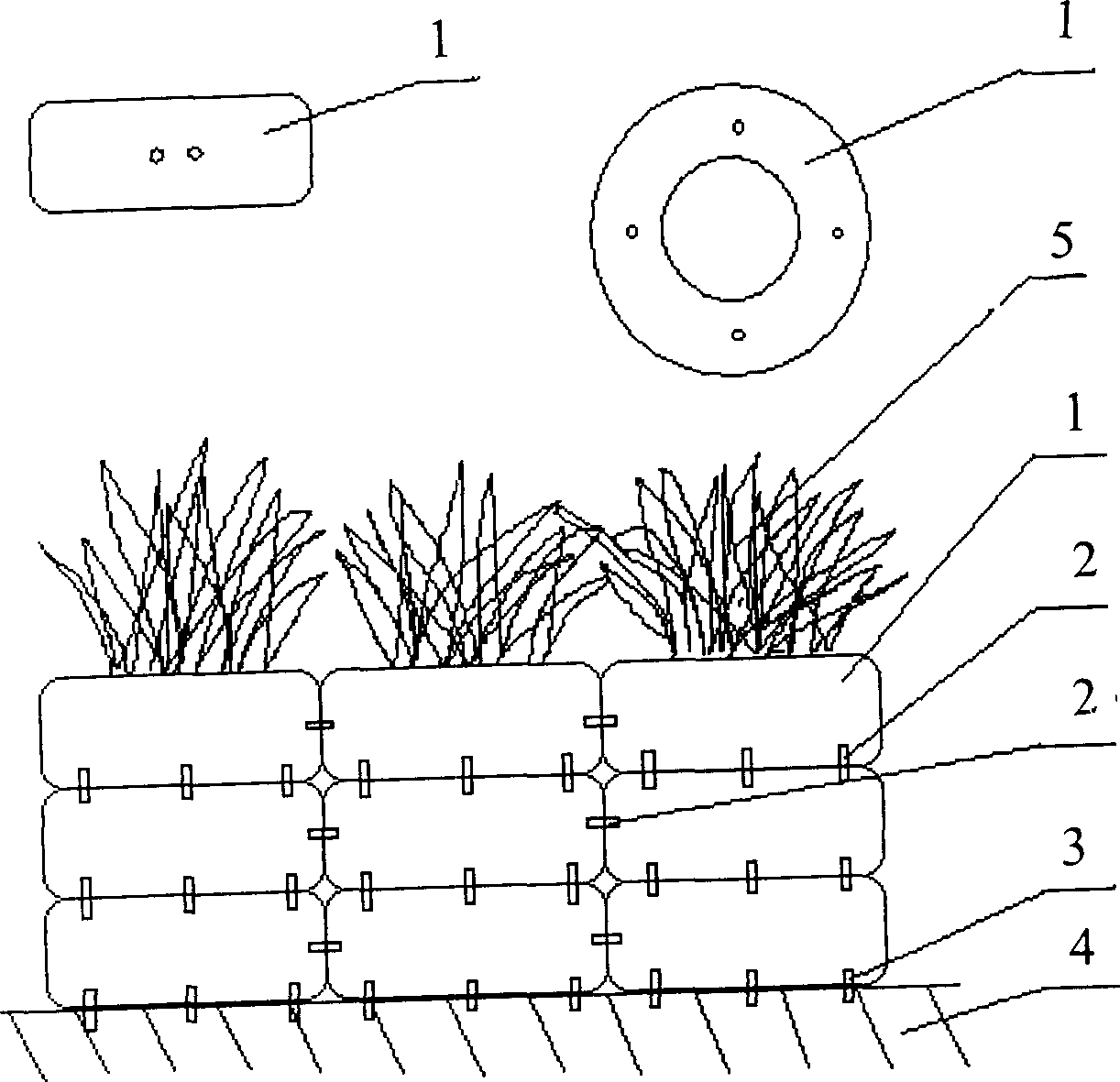

[0009] The present invention uses waste tires to build a method for road isolation green belt guardrails, see figure 1 , first select waste tires 1 with the same specifications, punch and drill 4 symmetrical bolt holes on the superimposed surface of tire 1, and punch and drill 1-2 symmetrical bolt holes on the connecting surface;

[0010] According to the height and length required by the isolation zone, each tire 1 is stacked and connected with bolts 2, and fixed on the ground 4 where the isolation zone is to be built with anchor bolts 3;

[0011] After installation, fill the soil for greening in the hollow in the middle of the tire 1, so as to plant flowers and plants 5.

[0012] The periphery of tire 1 can spray reflective or luminous paint.

[0013] The invention classifies the recycled waste tires according to the size and punches and drills the standard bolt holes to ensure that the appearance of each section of the isolation belt can be uniform, and it is handed over t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com