Semiconductor wafer and production method thereof

A technology of semiconductors and wafers, applied in the field of semiconductor wafers and their manufacturing, can solve the problem of wasting limited space on chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This case can be obtained through the following icons and detailed descriptions:

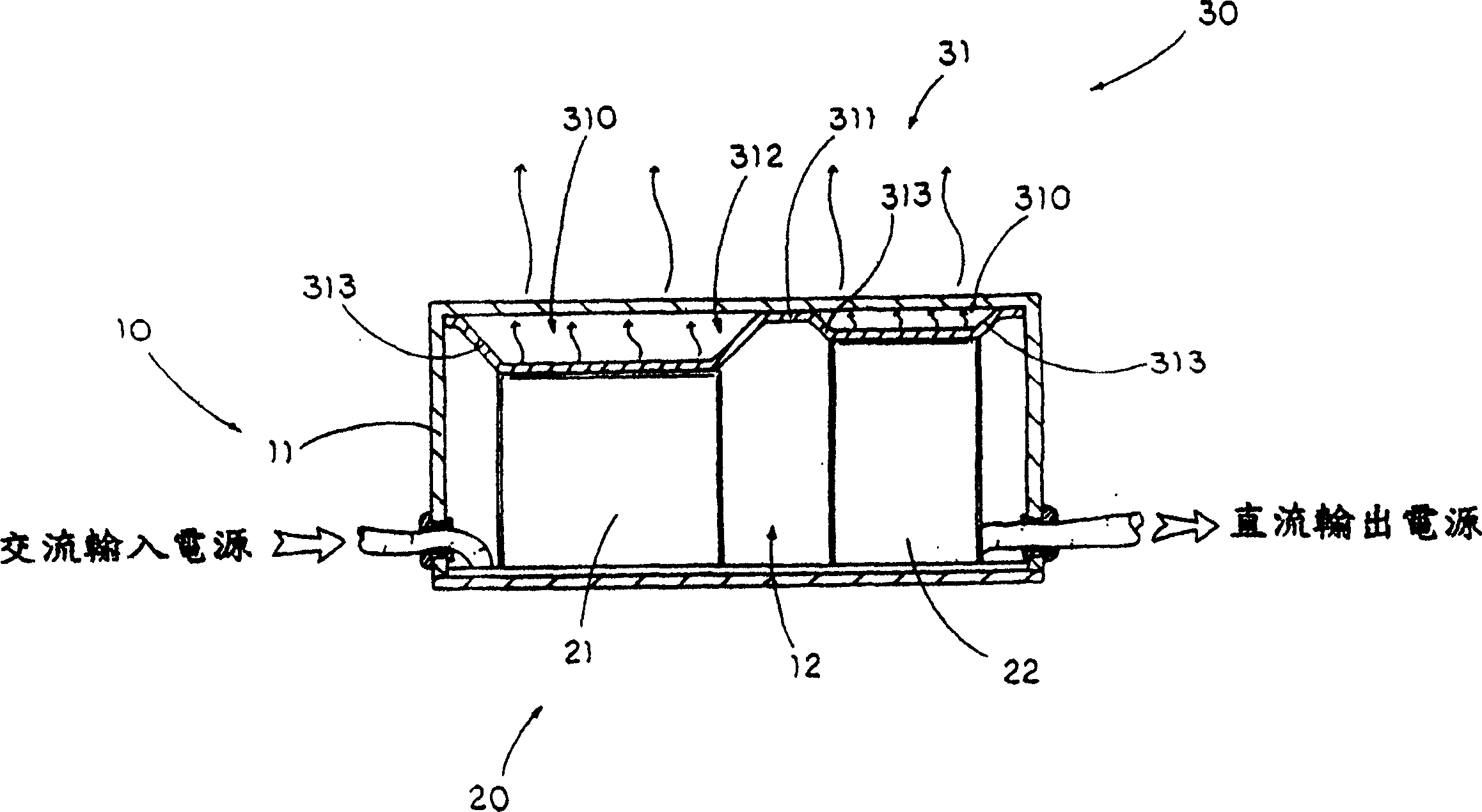

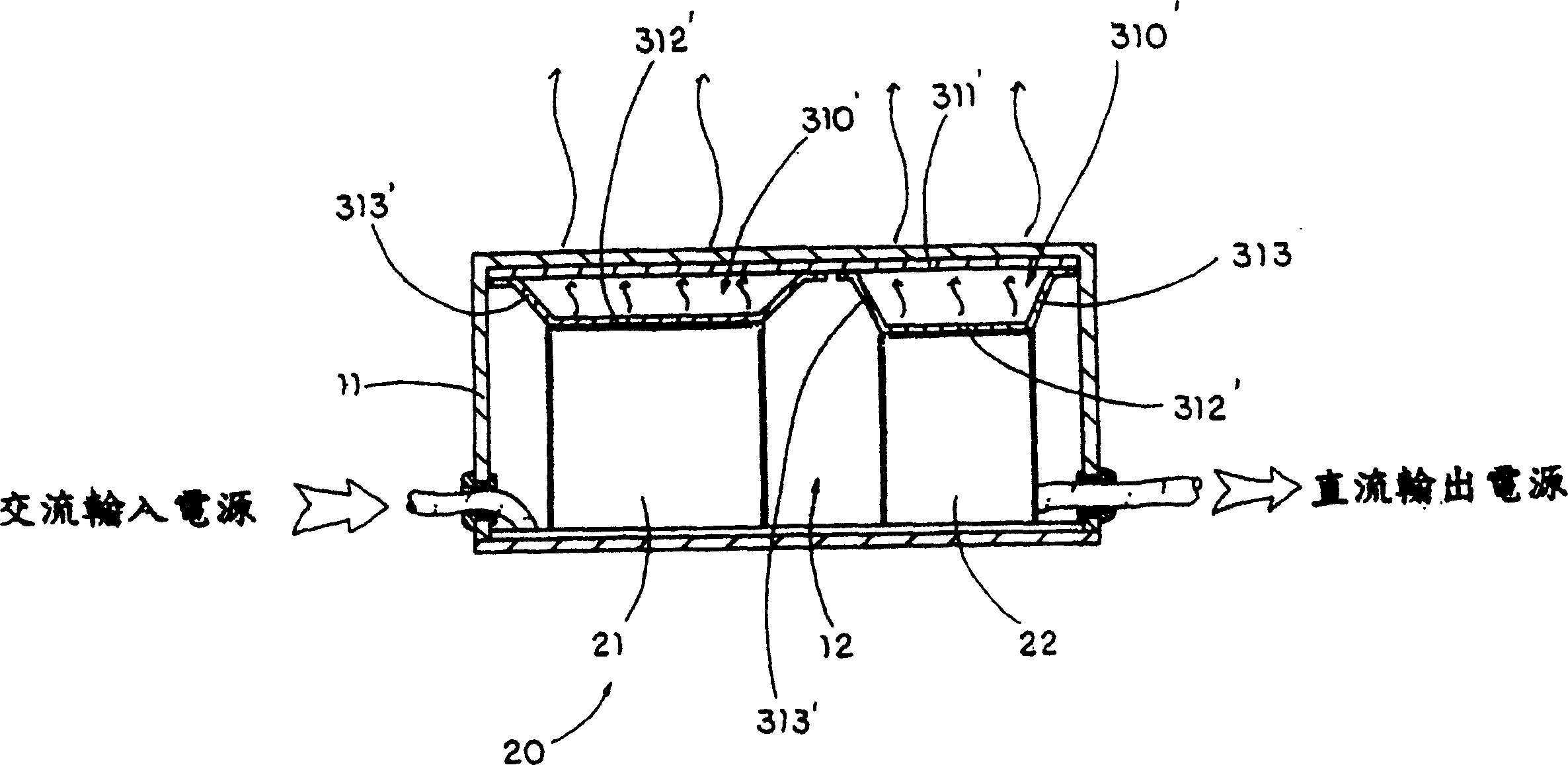

[0027] refer to figure 1 , is the top view of the semiconductor wafer of the preferred embodiment of the present case. Wherein, the semiconductor wafer includes a wafer body 10 and a plurality of analog IC chips 20 spaced and aligned on the wafer body 10 , and a region between every two chips 20 is defined as a dicing line 11 . Wherein, each of the chips 20 has an internal circuit 21 formed inside the chip and at least one terminal pad 22 formed along the dicing line 11 .

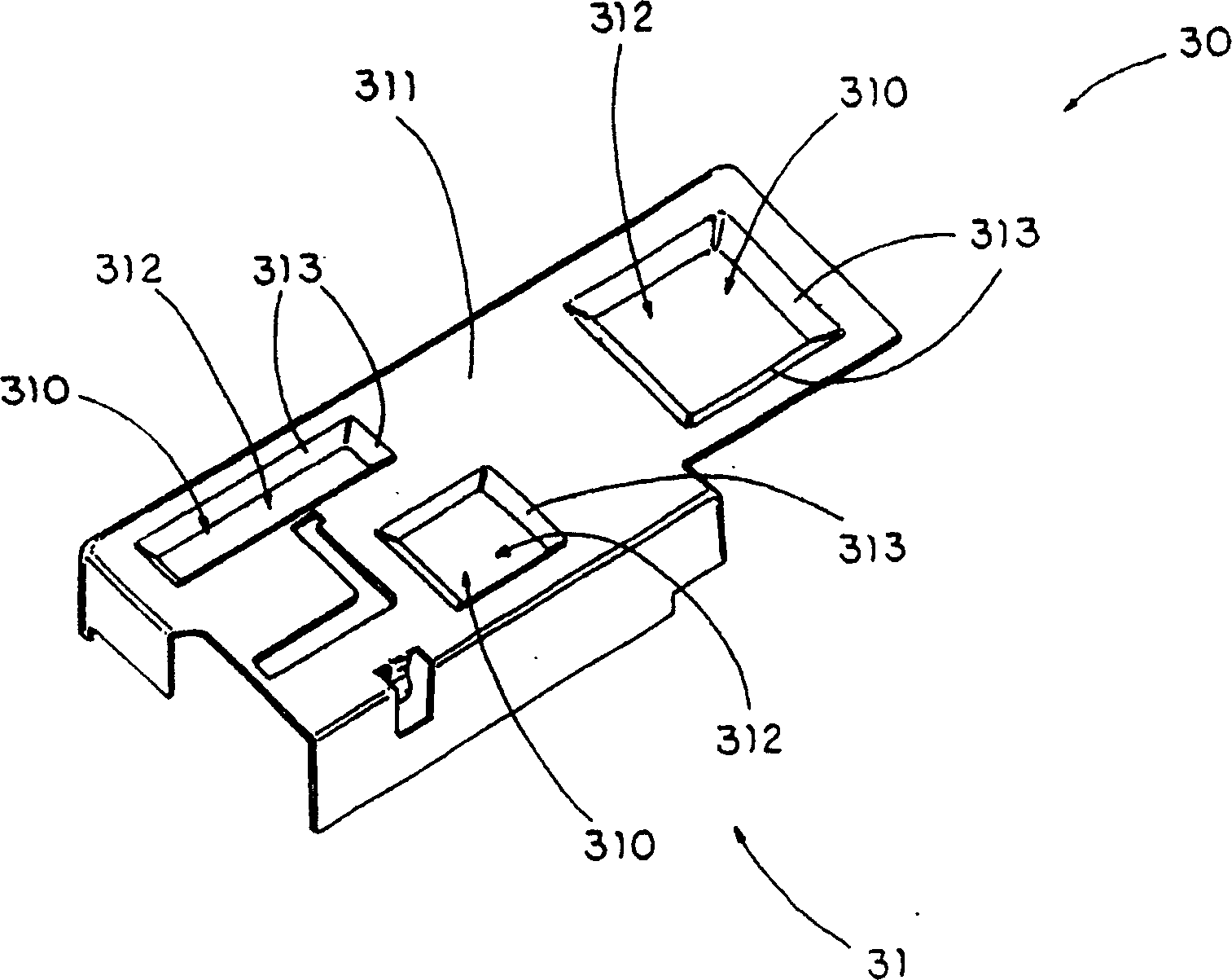

[0028] The semiconductor wafer further includes a conductive arrangement 30 comprising at least one conductive component 31 formed on the wafer body 10 to electrically connect the terminal pads 22 to the internal circuit 21 so that when the chip 20 is separated from the After cutting off the wafer body 10 , the terminal pads 22 can be cut off from the chip 20 so that the internal circuit 21 remains in the chip 20 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com