Sheet silicate mineral and fuel cell including intercalation complex thereof as solid electrolyte membrane

A solid electrolyte membrane, silicate mineral technology, applied in fuel cells, fuel cell additives, fuel cell components, etc., can solve the problems of methanol permeation, degradation of polymer membranes, and inability to improve output power, and achieve easy Preparation, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The best way to implement the invention

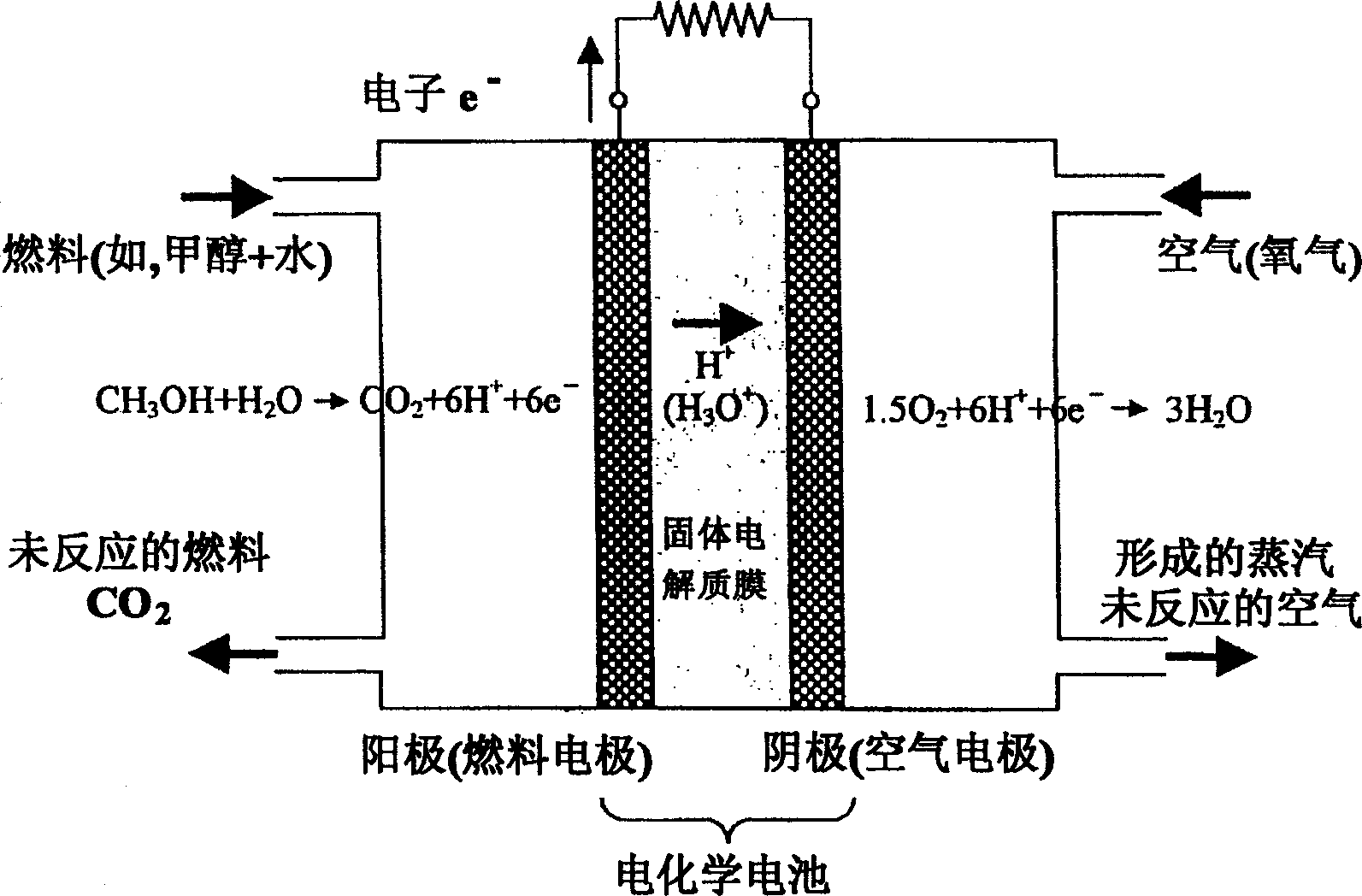

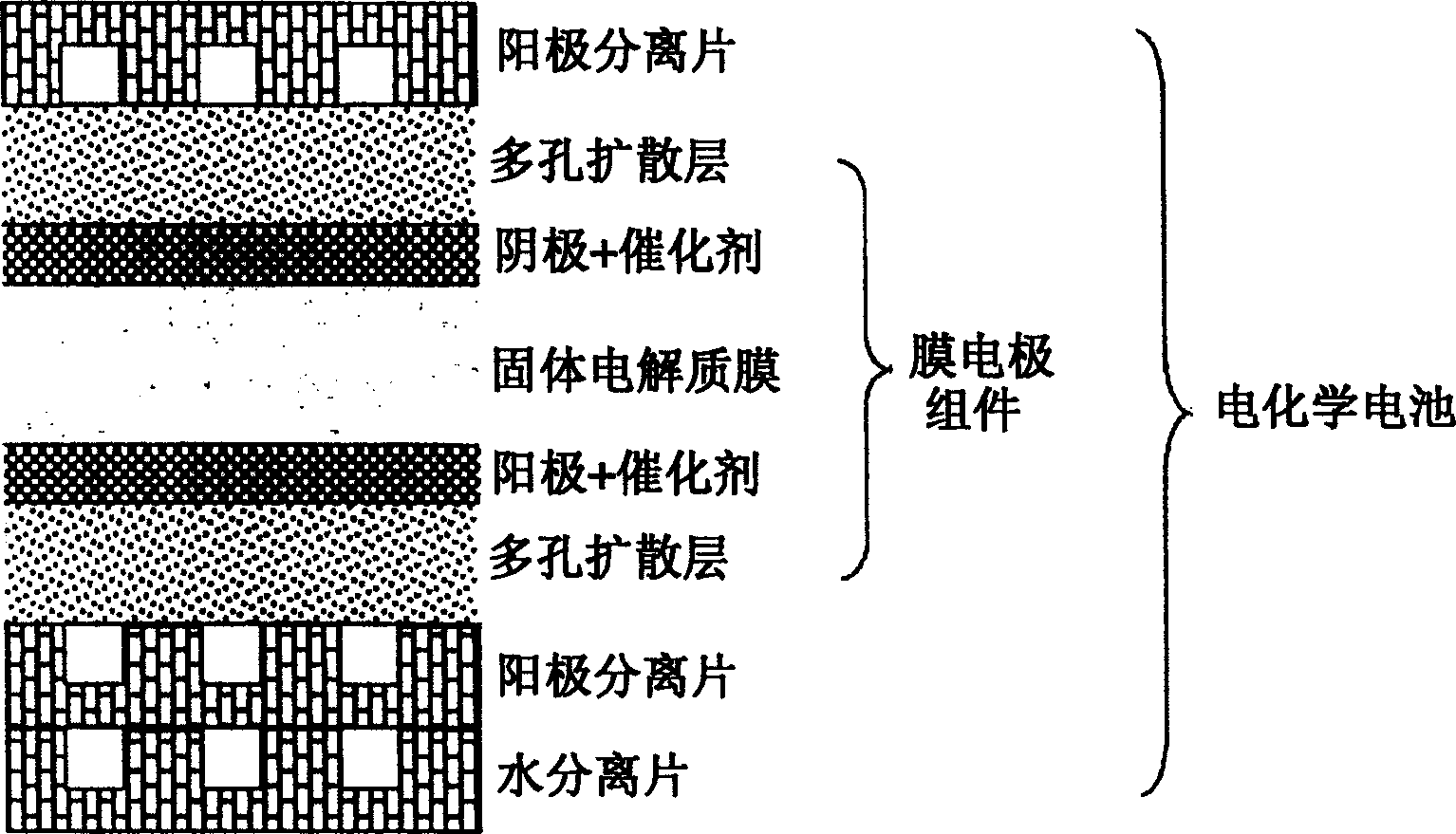

[0046] If the electrolyte can be produced, it is possible to build on the basis of existing technology such as figure 1 The electrochemical cell is shown, and the fuel cell system is formed by stacking the cells.

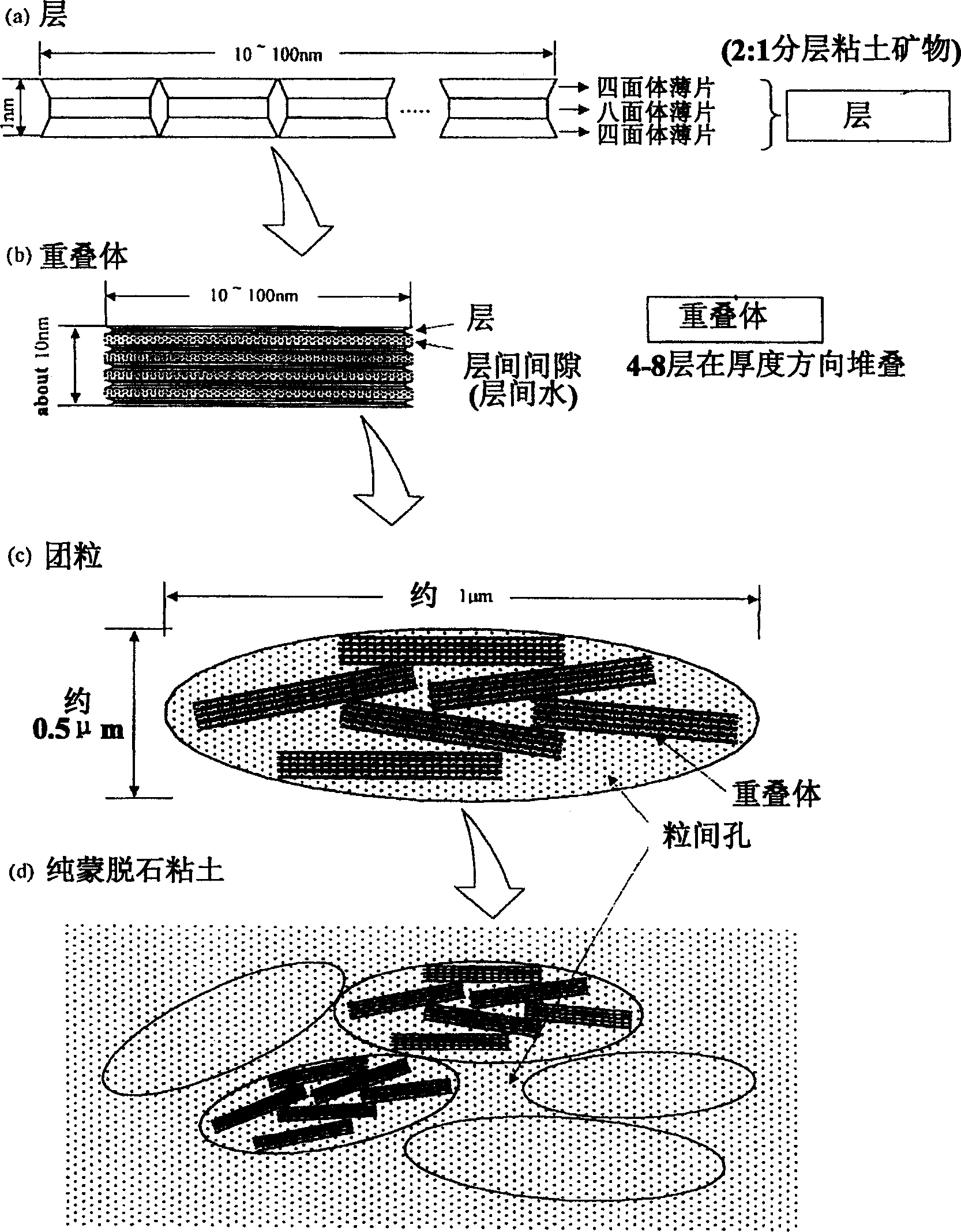

[0047] If the density and immersion liquid content are appropriately controlled when producing layered silicate membranes or interlayer compound membranes, fuel permeation can be avoided. Due to the molecular sieve effect of the layered silicate membrane, the two contradictory properties of high proton conductivity and low fuel permeability can be satisfied at the same time.

[0048] according to Figure 7 According to the experimental results, ethanol is the preferred fuel for direct fuel cells using layered silicate membranes. In addition, if the density and immersion liquid content are strictly controlled when producing layered silicate membranes, it is possible to produce layered silicate membranes with solid electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com