Railway box wagon heat-isolating layer and its production method

A railway box car and heat insulation layer technology, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of reducing the load and volume of trains, increasing the weight of trains, and not being able to meet the needs of trains, so as to achieve good heat insulation effect and low weight. Lightweight and takes up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

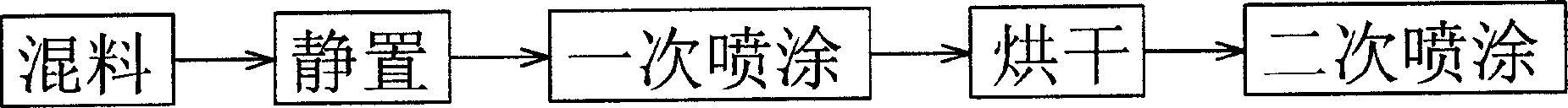

Method used

Image

Examples

Embodiment 1

[0012] The railway box car insulation layer is composed of 100 parts of epoxy resin (such as: E-51, E-618 and other models), 85 parts of epoxy curing agent (such as: 115, 125, 140 and other models) according to the ratio of parts by weight, 36 parts of industrial grade alcohol (more than 95%), 35 parts of short fiber (commonly known as fluff or plush), 32 parts of thickening powder (such as polyphenyl powder, perlite and other light heat insulation powder), 25 parts of color masterbatch and hair The foaming agent is composed of 0.8 parts. The short fiber can be nylon 66 or nylon 6, with a thickness of 1.5-3.0D and a length of 0.3-0.6mm. The fineness of the thickening powder is 200-1000 mesh. The agent is composed of aluminum powder and saturated sodium hydroxide solution, and the weight-number ratio of the aluminum powder and the saturated sodium hydroxide solution is 2:1 or 1.5:1 or 1:1, and the fineness of the aluminum powder is 200-1000 mesh.

Embodiment 2

[0014] The railway box car insulation layer is composed of 140 parts of epoxy resin (such as: E-51, E-618 and other models), 60 parts of epoxy curing agent (such as: 115, 125, 140 and other models) according to the ratio of parts by weight, 50 parts of industrial grade alcohol (more than 95%), 24 parts of short fiber (commonly known as fluff or plush), 45 parts of thickening powder (such as polyphenyl powder, perlite and other light heat insulation powder), 16 parts of color masterbatch and hair The foaming agent consists of 1.6 parts, and the type of said short fiber is nylon 66 or nylon 6, the thickness is 1.5-3.0D, and the length is 0.3-0.6mm. Said thickening powder fineness is 200~1000 orders, and foaming agent can adopt aluminum powder and sodium hydroxide saturated solution, and the weight-number ratio of aluminum powder and sodium hydroxide saturated solution is 2: 1 or 1.6: 1 or 1:1, the fineness of aluminum powder is 200-1000 mesh.

Embodiment 3

[0016] The railway boxcar insulation layer is composed of 120 parts of epoxy resin (such as: E-51, E-618 and other models), 73 parts of epoxy curing agent (such as: 115, 125, 140 and other models) according to the ratio of parts by weight, Composed of 42 parts of industrial grade alcohol (above 95%), 30 parts of short fiber, 39 parts of thickening powder (such as polyphenyl powder, perlite and other light heat insulation powder), 20 parts of color masterbatch and 1.2 parts of foaming agent. The short fiber type mentioned is nylon 66 or nylon 6, the thickness is 1.5-3.0D, and the length is 0.3-0.6mm. The fineness of said thickening powder is 200-1000 mesh, and the foaming agent is aluminum powder and saturated sodium hydroxide solution, and the weight-number ratio of aluminum powder and saturated sodium hydroxide solution is 2:1 or 1.5:1 or 1 : 1, the fineness of aluminum powder is 200-1000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com