Measurement of steel slag age

A technology for rapid determination of steel slag, applied in the direction of material resistance, etc., can solve problems such as lack of stability of steel slag, and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

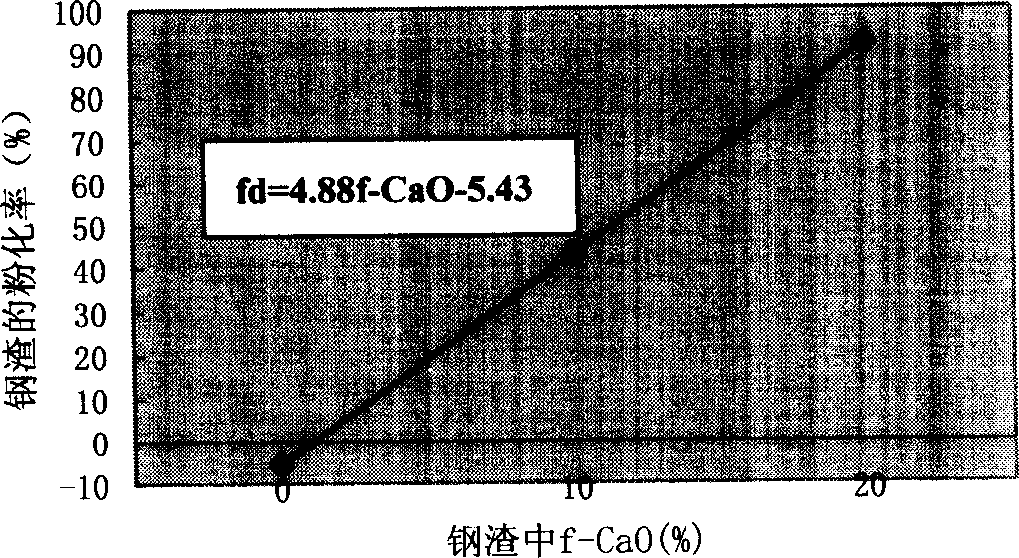

Method used

Image

Examples

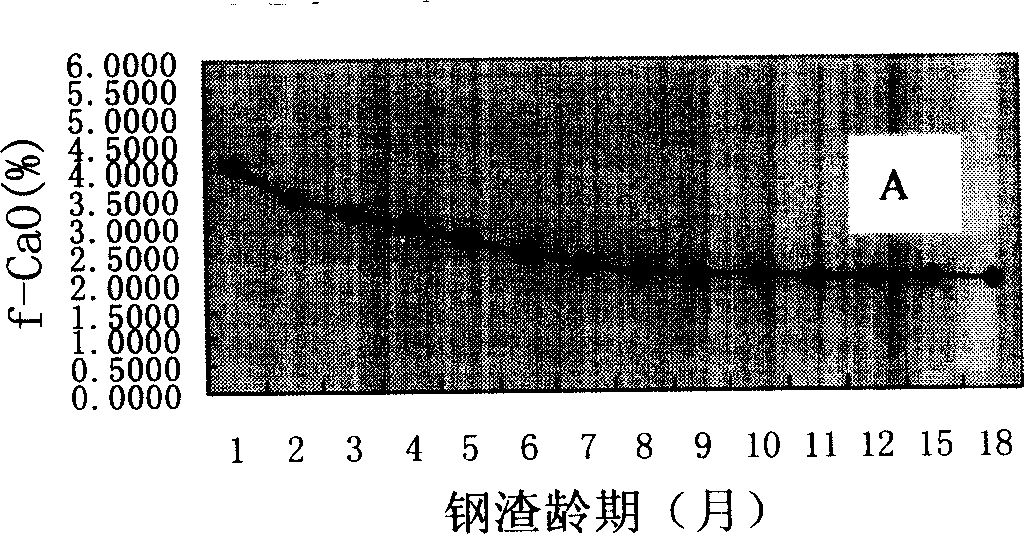

Embodiment 1

[0041] Example 1 Accurately weigh 0.2g of the steel slag to be tested in a dry 50mL beaker, add 20mL of ethylene glycol, put in a constant temperature water bath at a super constant temperature of 90°C for 5 minutes, insert an electrode to measure the conductivity, and determine the content of free calcium oxide by calculating the formula 2.019 %. The age of the steel slag is 15 months from the relationship diagram of the free calcium oxide content of the steel slag and the storage period of the steel slag in saturated water vapor at a temperature greater than 100°C.

Embodiment 2

[0042] Example 2 Accurately weigh 0.2g of the steel slag to be tested in a dry 50mL beaker, add 20mL of ethylene glycol, put in a constant temperature water bath at a super constant temperature of 90°C for 5 minutes, insert an electrode to measure the conductivity, and use the calculation formula to determine the content of free calcium oxide 2.0514 %. The age of the steel slag is 11 months obtained from the relationship diagram between the free calcium oxide content of the steel slag and the storage period of the steel slag in saturated water vapor at a temperature greater than 100°C.

Embodiment 3

[0043] Example 3 Accurately weigh 0.2g of the steel slag to be tested in a dry 50mL beaker, add 20mL of ethylene glycol, put it in a constant temperature water bath at a super constant temperature of 90°C for 5 minutes, insert an electrode to measure the conductivity, and use the calculation formula to determine the content of free calcium oxide 2.0313 %. The age of the steel slag is 12 months obtained from the relationship diagram between the free calcium oxide content of the steel slag and the storage period of the steel slag in saturated water vapor at a temperature greater than 100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com