Production technology of dummy porcelain polished brick, and polishing and grinding device thereof

A production process and technology for polishing tiles, which are used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., to achieve the effects of less abrasive block wear, less polishing noise, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

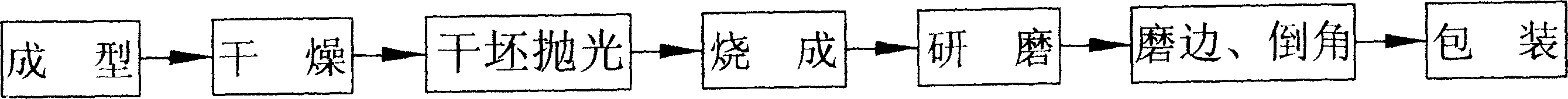

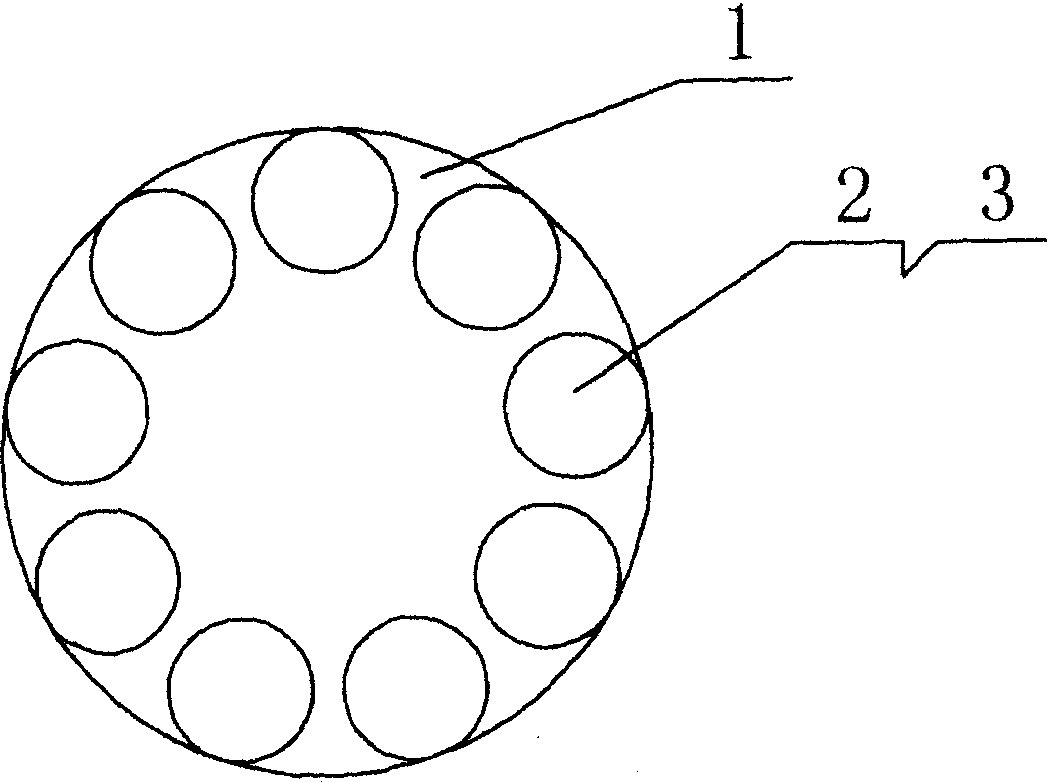

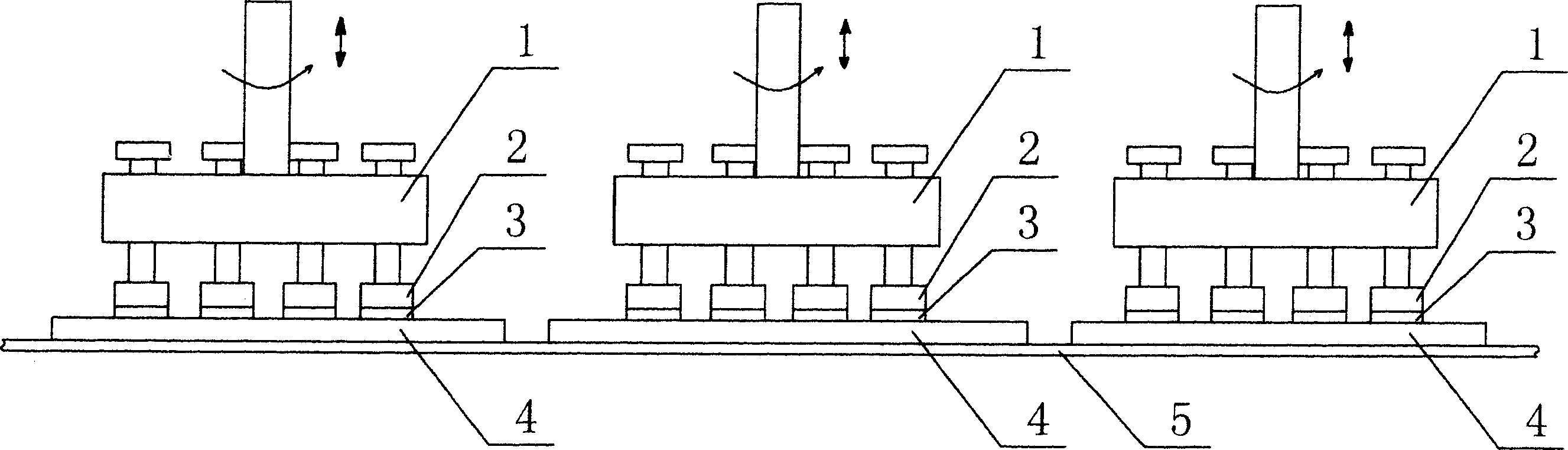

[0021] Such as figure 1 , figure 2 As shown, the production process of the matt porcelain polished tiles of the present invention includes the following steps: forming-drying-dry polishing-firing-grinding-edging, chamfering-packaging. The dry body polishing is to polish the dry body with a moisture content of less than 1.5% by polishing equipment, and the polishing depth is 0.1-5mm; after the polishing process, there may be glazing, printing, knurling and other decorative processes; The firing step is one or more firing; the grinding step is to slightly grind the fired green body by a grinding device to remove coarse particles, and can be set before or after the edging and chamfering steps. The dry blank polishing equipment is composed of at least three sets of planetary polishing devices, and each set of planetary polishing devices is composed of a large rotatable grinding head 1 and at least six small grinding heads 2 that can rotate on its own. The diameters are evenly distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com