Correction method of evenness of film thickness of electron beam evaporation film coating

A technology of electron beam evaporation and uniform film thickness, which is applied in vacuum evaporation plating, ion implantation plating, sputtering plating, etc., can solve the problems of increasing labor and cost, and not really grasping the uniformity, so as to improve Effect of Thickness Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

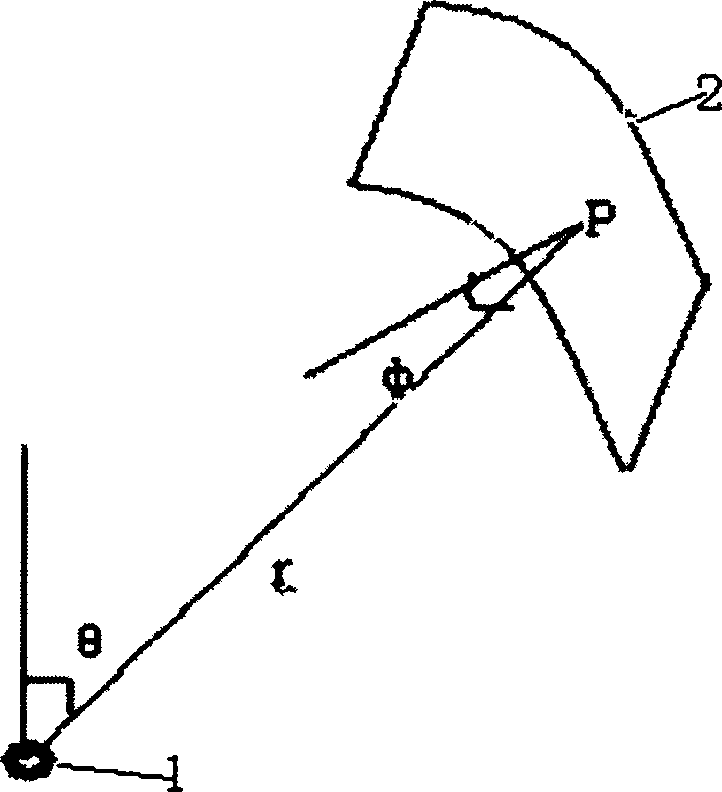

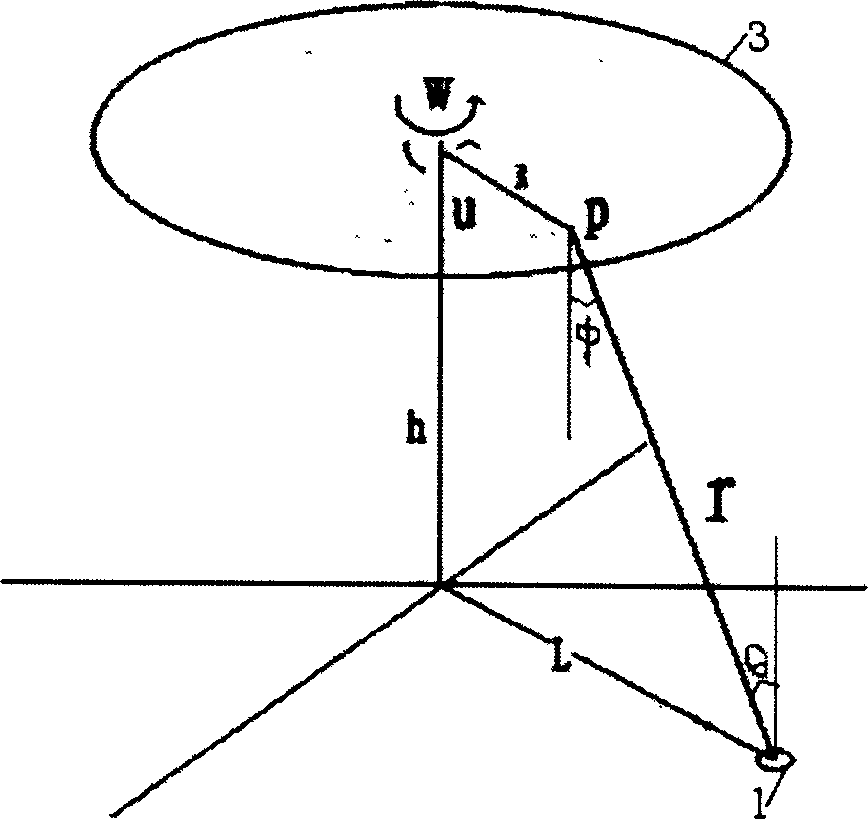

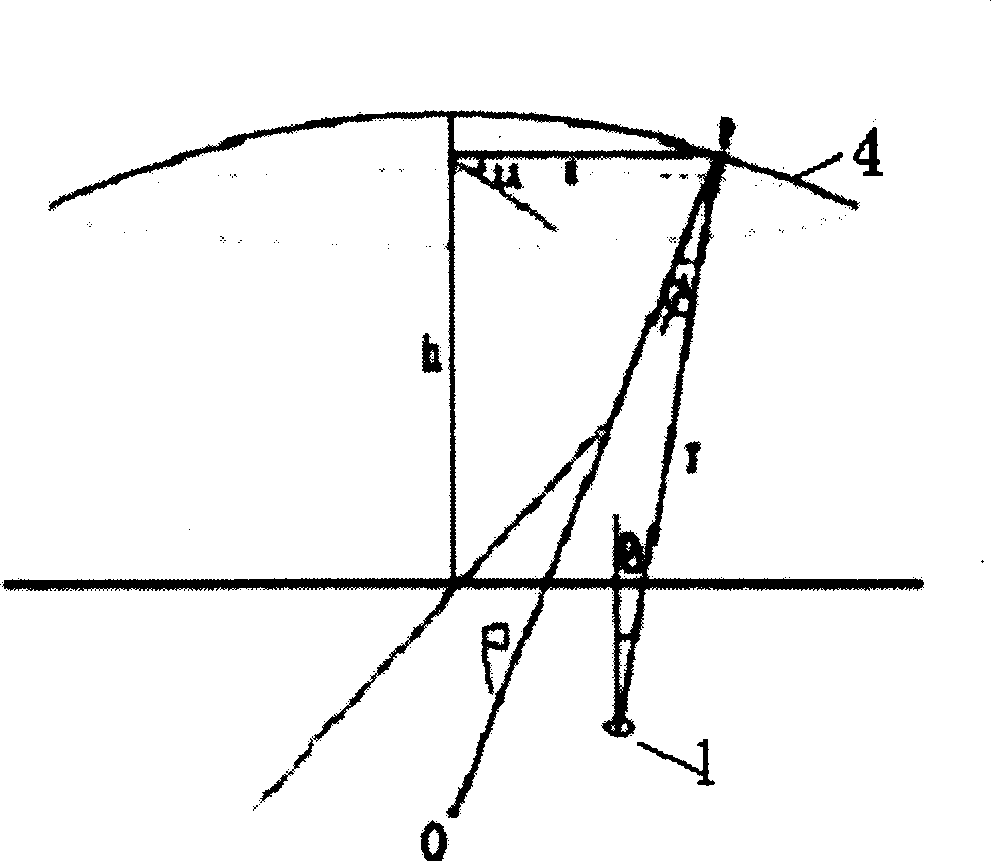

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0038] The basis of the program of the present invention is as follows:

[0039] Thickness uniformity is a common problem in the production of optical films. There are many factors that affect the thickness uniformity of optical films, but in general it can be attributed to two aspects:

[0040] 1. The geometric configuration of the vacuum chamber, such as the distance of the electron beam evaporation source from the central axis of the vacuum chamber, the height of the fixture, the shape of the fixture and other system factors.

[0041] 2. The evaporation characteristics of the evaporation source are related to factors such as the type of material, the evaporation parameters during coating, and the way the operator operates the electron beam evaporation source.

[0042] In theory, evaporation sources can be divided into two categories: point evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com