Split type permanent magnet synchronous wind driven electric generator

A wind turbine and permanent magnet synchronous technology, which is applied in the direction of wind turbine components, wind engines, wind motor combinations, etc., can solve the problems of inconvenient transportation and installation, shutdown maintenance, low power generation efficiency, etc., to reduce transportation and installation costs , Reduce the probability of failure, improve the effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

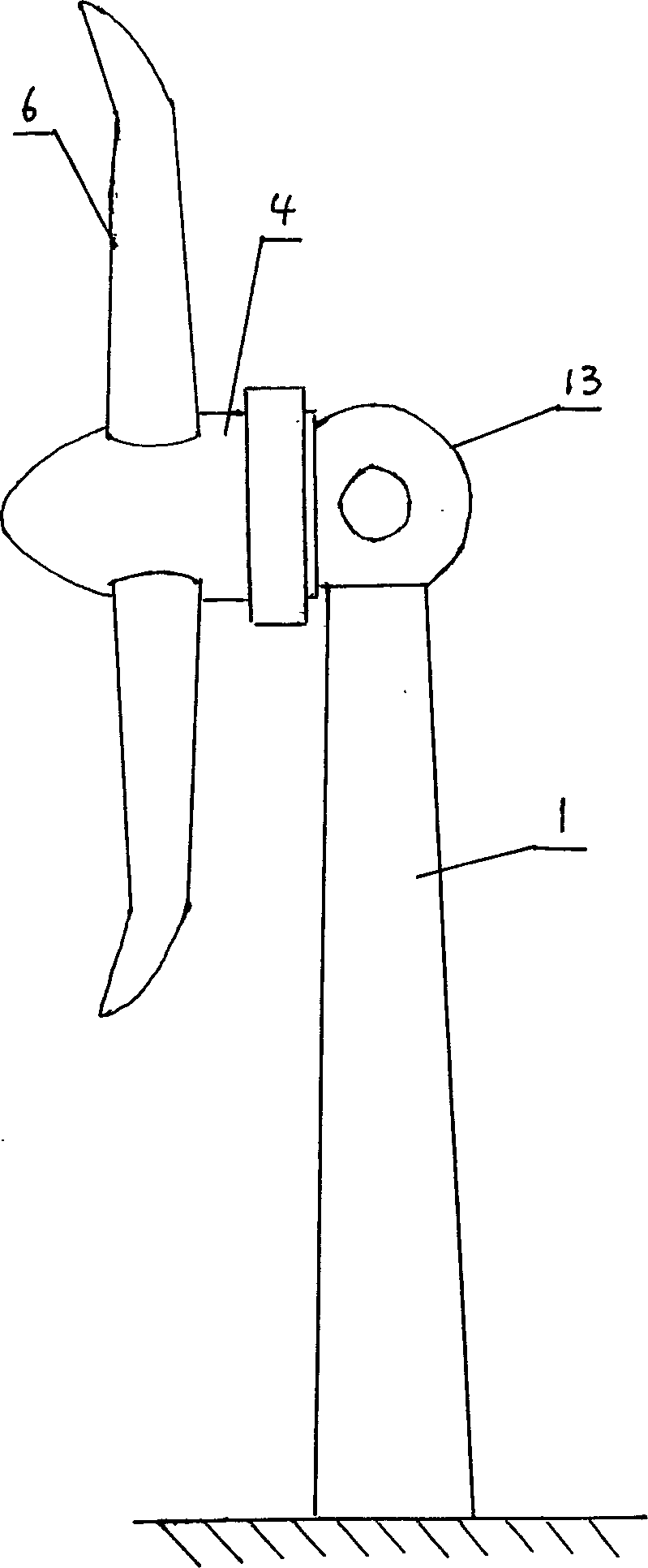

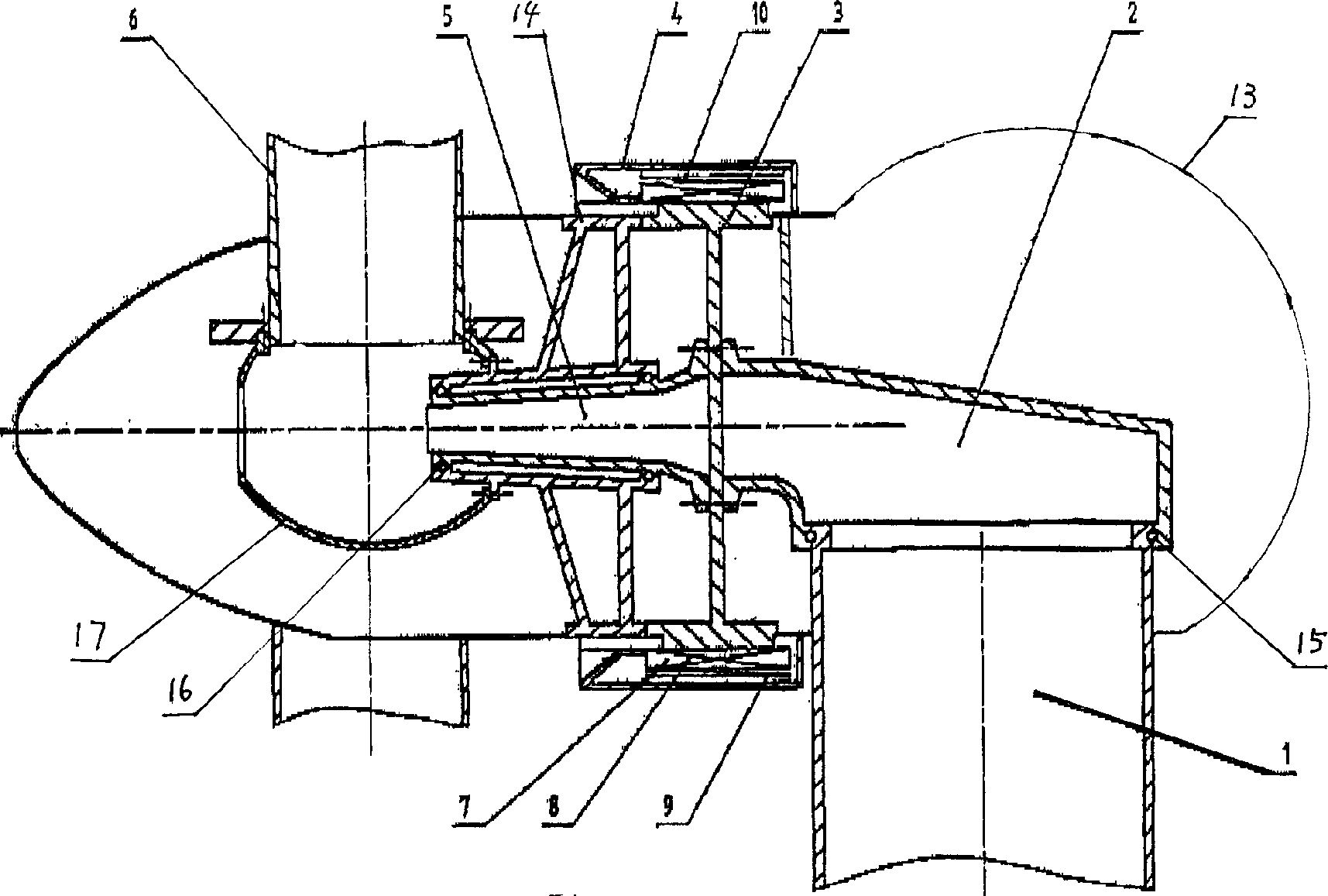

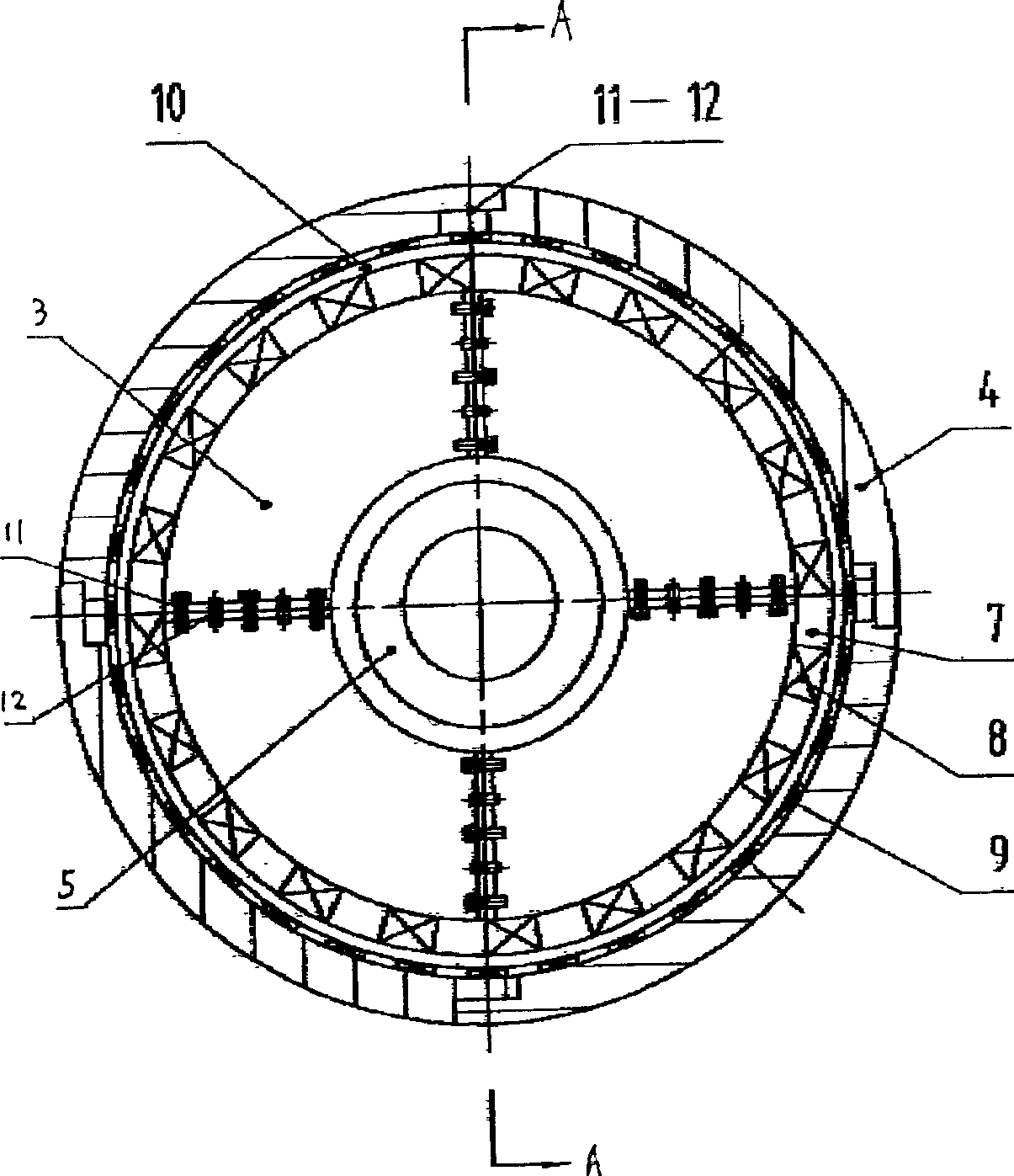

[0018] Referring to the accompanying drawings, the split type permanent magnet synchronous wind power generator described in the embodiment includes a tower 1, the upper end of the tower 1 is connected with a revolving body 2 through a bearing 15, and the revolving body 2 is fixedly connected in the inner cavity of the nacelle 13, The rear section of the nacelle 13 is in the shape of a hemispherical shell. The stator bracket 3 and the central shaft 5 are fixedly connected to the rotating body 2. The central shaft 5 is connected to the turntable 14 through the bearing 16. The rotor casing 4 is fixedly connected to the turntable 14. The rotor casing The blade end of 4 is streamlined, the blade 6 is fixedly connected to the turntable 14 through the hub 17, and the evenly distributed stator core 7 is inlaid on the circumferential surface of the stator bracket 3, and the three-phase coil winding 8 is wound on the stator core 7. A permanent magnet 9 is inlaid on the inside of the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com