Preparing multipurpous carbon with regular constructure and high ratio surface area by mould board carbonizing process

A high specific surface area, porous carbon technology, applied in the field of carbon material science, can solve the problems of imperfect process conditions and technology, long preparation cycle, etc., achieve the effect of shortening the preparation cycle, improving filling efficiency, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

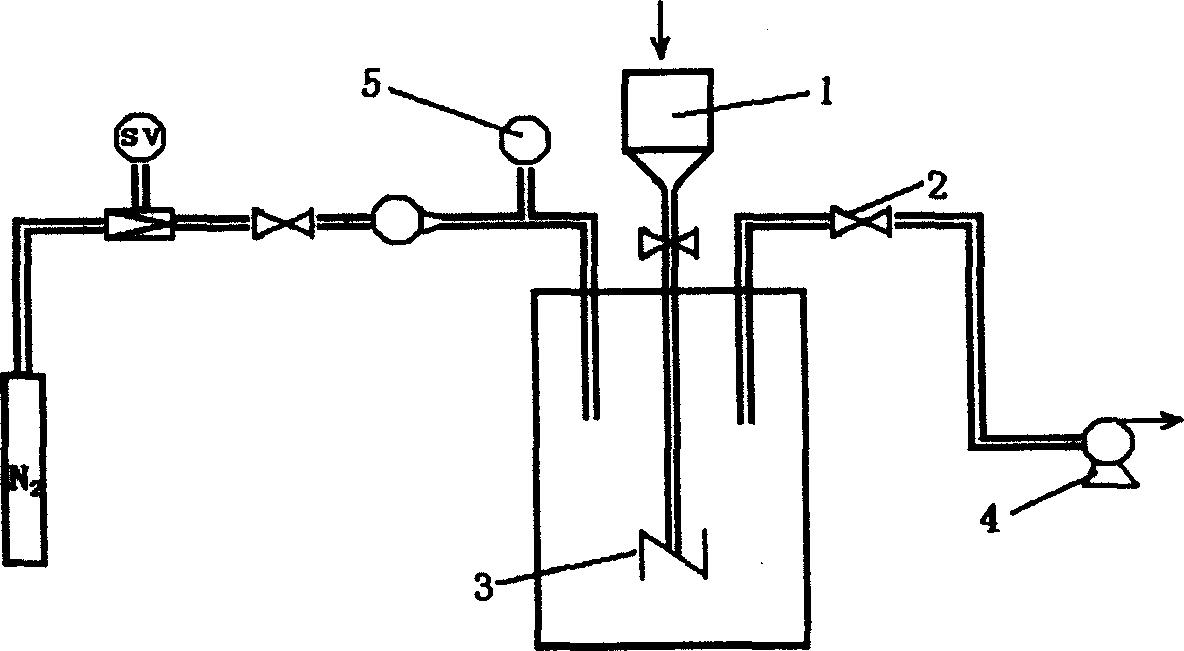

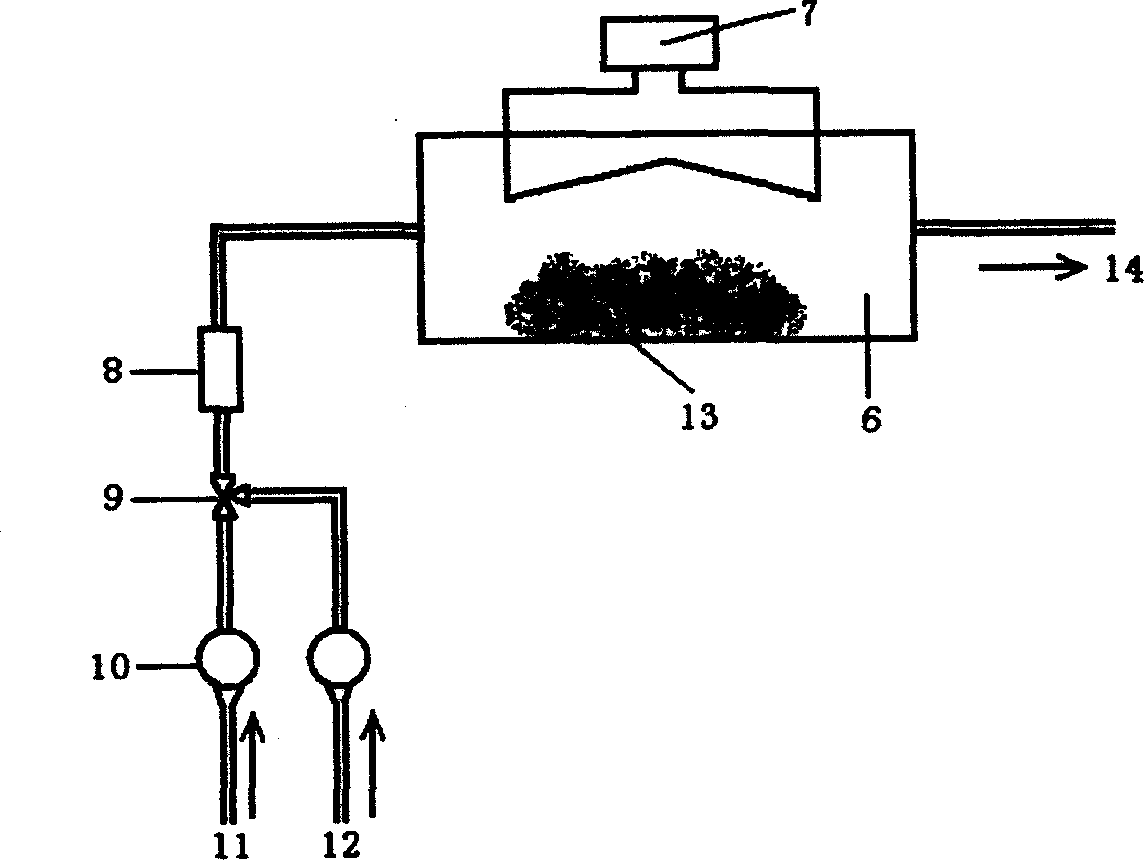

[0032] Using organic furfuryl alcohol (FA) as carbon precursor, powdery commercial Y-type zeolite (SiO 2 / Al 2 o 3 =7.4) as a template, and the template carbonization method prepares porous carbon with regular structure and high specific surface area. The specific steps are as follows: 1. Weigh 3 g of powdery Y-type zeolite and dry it under vacuum at 120° C. for 1 hour. 2. Add 10ml of FA to the dry powdered Y-type zeolite under vacuum at room temperature, and start stirring. After 30 minutes, nitrogen gas is introduced to continue stirring for 8 hours, and then impregnated under 1.0MPa nitrogen pressure for 1.2 hours. 3. Filter the FA / Y type zeolite mixture and dry it under air to obtain dry FA / Y type zeolite. 4. The FA / Y-type zeolite obtained in step 3 is washed with o-xylene to remove the FA remaining on the outer surface of the Y-type zeolite (stirring time is 10min), and the FA / zeolite composite is obtained after filtering to remove the detergent and further drying in t...

Embodiment 2

[0034] Using organic furfuryl alcohol (FA) as carbon precursor, powdery commercial Y-type zeolite (SiO 2 / Al 2 o 3 =7.4) as a template, and the template carbonization method prepares porous carbon with regular structure and high specific surface area. The specific steps are as follows: 1. Weigh 5 g of powdery Y-type zeolite and dry it under vacuum at 120° C. for 1 hour. 2. Add 15mL of FA to the dry powdered Y-type zeolite under vacuum at room temperature, and start stirring. After 30 minutes, nitrogen gas is introduced and stirring is continued for 8 hours, and then impregnated under 1.2MPa nitrogen pressure for 1.5 hours. 3. Filter the FA / Y type zeolite mixture and dry it under air to obtain dry FA / Y type zeolite. 4. Wash the FA / Y-type zeolite obtained in step 3 with o-xylene to remove FA remaining on the outer surface of the Y-type zeolite (stirring time is 10 min), filter to remove the detergent, and dry under air to obtain the FA / zeolite composite. 5. Put the FA / zeolit...

Embodiment 3

[0036] Using organic furfuryl alcohol (FA) as carbon precursor, powdery commercial Y-type zeolite (SiO 2 / Al 2 o 3 =7.4) as a template, and the template carbonization method prepares porous carbon with regular structure and high specific surface area. The specific steps are as follows: 1. Weigh 10 g of powdery Y-type zeolite and dry it under vacuum at 120° C. for 1 hour. 2. Add 25mL of FA to the dry powdered Y-type zeolite under vacuum at room temperature, and start to stir. After 30min, nitrogen gas is introduced to continue stirring for 8h, and then impregnated under 1.2MPa nitrogen pressure for 1.5h. 3. Filter the FA / Y type zeolite mixture and dry it under air to obtain dry FA / Y type zeolite. 4. Wash the FA / Y-type zeolite obtained in step 3 with o-xylene to remove FA remaining on the outer surface of the Y-type zeolite (stirring time is 10 min), filter to remove the detergent, and dry under air to obtain the FA / zeolite composite. 5. Put the FA / zeolite composite obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com