Process for cooling of high temp. sodium carbonate

A cooling process, soda ash technology, applied in the direction of alkali metal compounds, alkali metal carbonates, inorganic chemistry, etc., can solve the problems of increasing cooling water flow, small contact area, low efficiency, etc., to speed up the cooling process and dust removal efficiency High, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

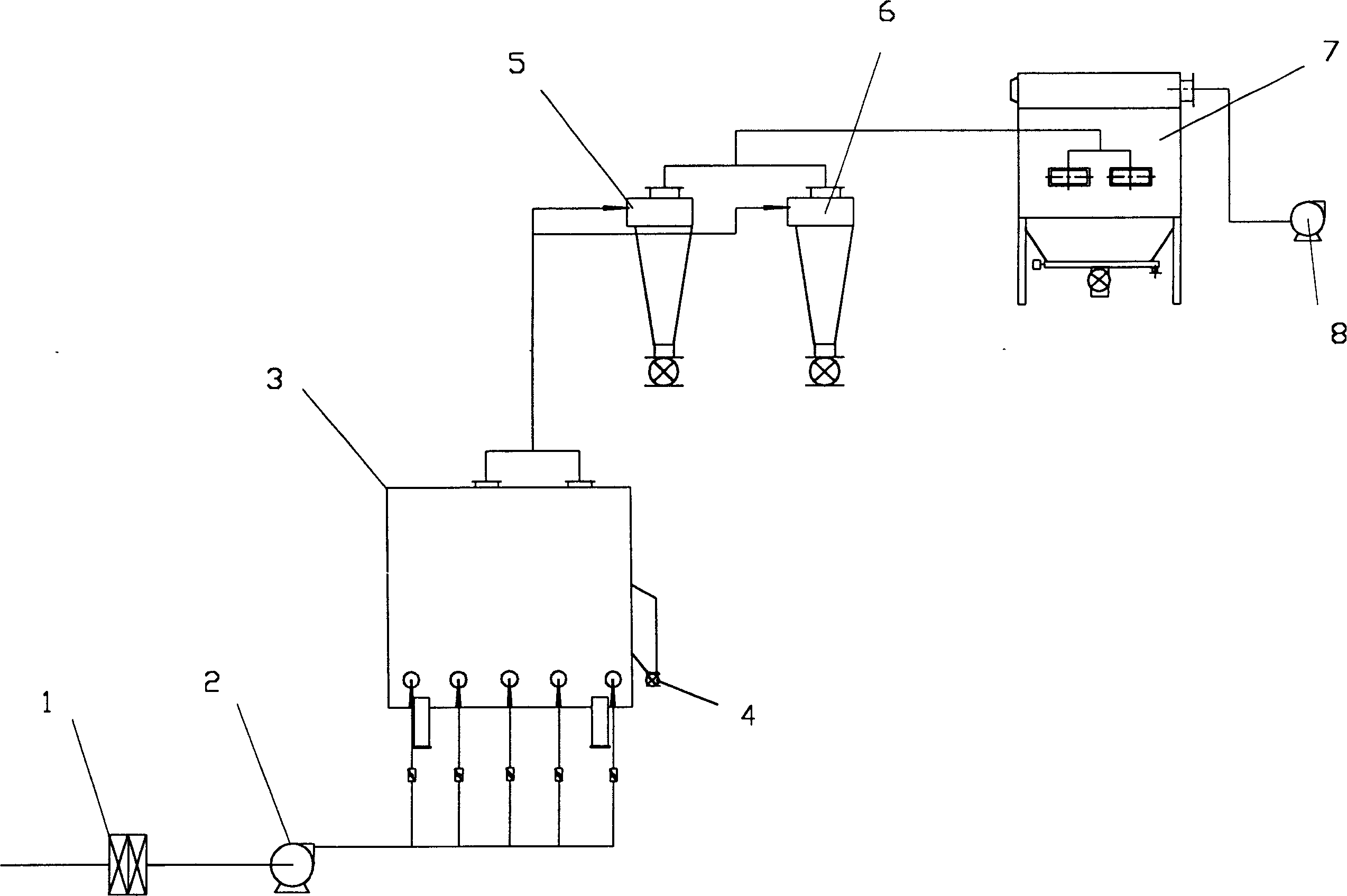

[0013] Accompanying drawing has provided process flow chart of the present invention. The high-temperature soda ash at a temperature of 160°C enters the fluidized bed cooler 3 through the conveying equipment, and is relatively uniformly dispersed into the bed through the built-in distributor of the fluidized bed cooler 3 . After the air is filtered and dedusted by the air filter 1, it enters the blower 2, which is powered by the blower 2 to form cold air and enters the fluidized bed cooler 3. On the one hand, the material is kept in a normal fluidized state, and on the other hand, it is separated from the material. Heat exchange to cool down the material. The fluidized state means that the material in the equipment is blown by the fluid and suspended in the fluid for free movement under a certain wind speed. The particles collide and mix with each other, and the bed height rises. There is a substantially horizontal material surface at the top of the layer, on which particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com