Fabricating method of decorative board and decorative board made by the same

A manufacturing method and technology for decorative panels, which are used in manufacturing tools, joining of wooden veneers, papermaking, etc., can solve the problems of rising costs, weak tolerance, and increased production costs of products, preventing separation and reducing production. Cost, effect of preventing discoloration of cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

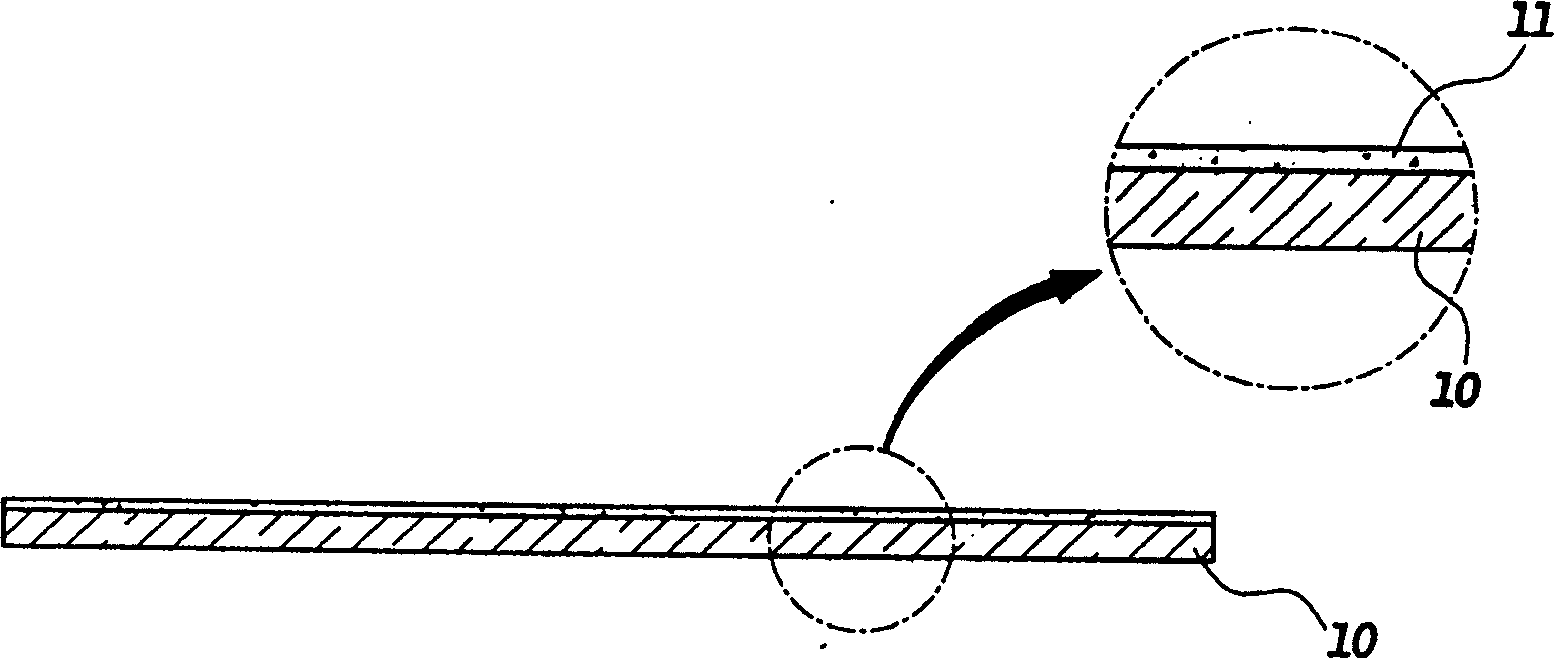

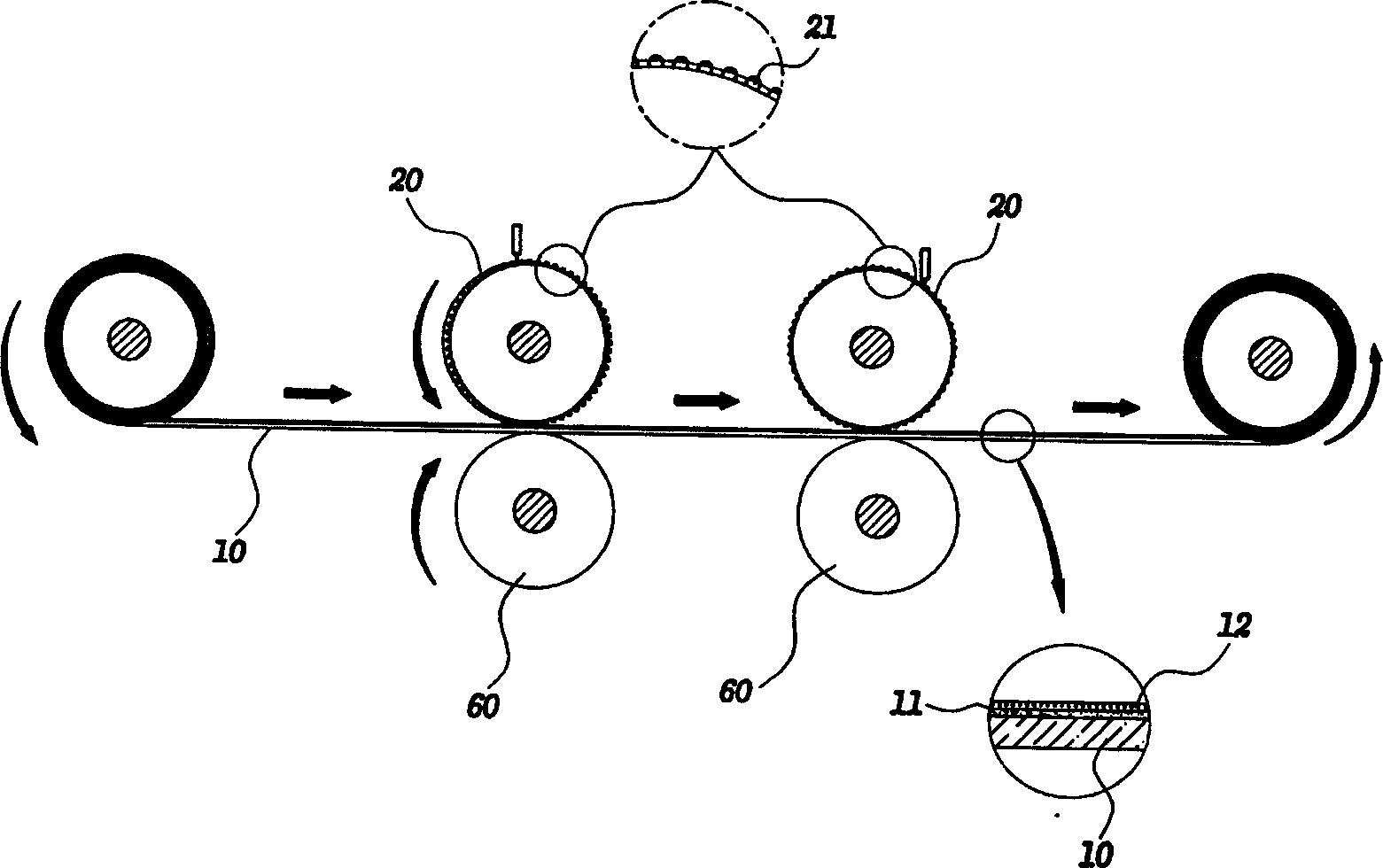

[0045] In the present invention, the ultra-thin cardboard printed with various patterns or patterns on one side is passed through the first and second steel rolls with a plurality of concavities and convexities formed on the surface, and the resin liquid supplied from the steel rolls is forcibly infiltrated and coated. On the cardboard, glue it to one side or both sides of the bottom board formed by ordinary plywood bottom board, PB, MDF, HDF and other high, medium and low density compressed reinforced wood with adhesive etc., and carry out hot press stamping processing to obtain Decorative plates.

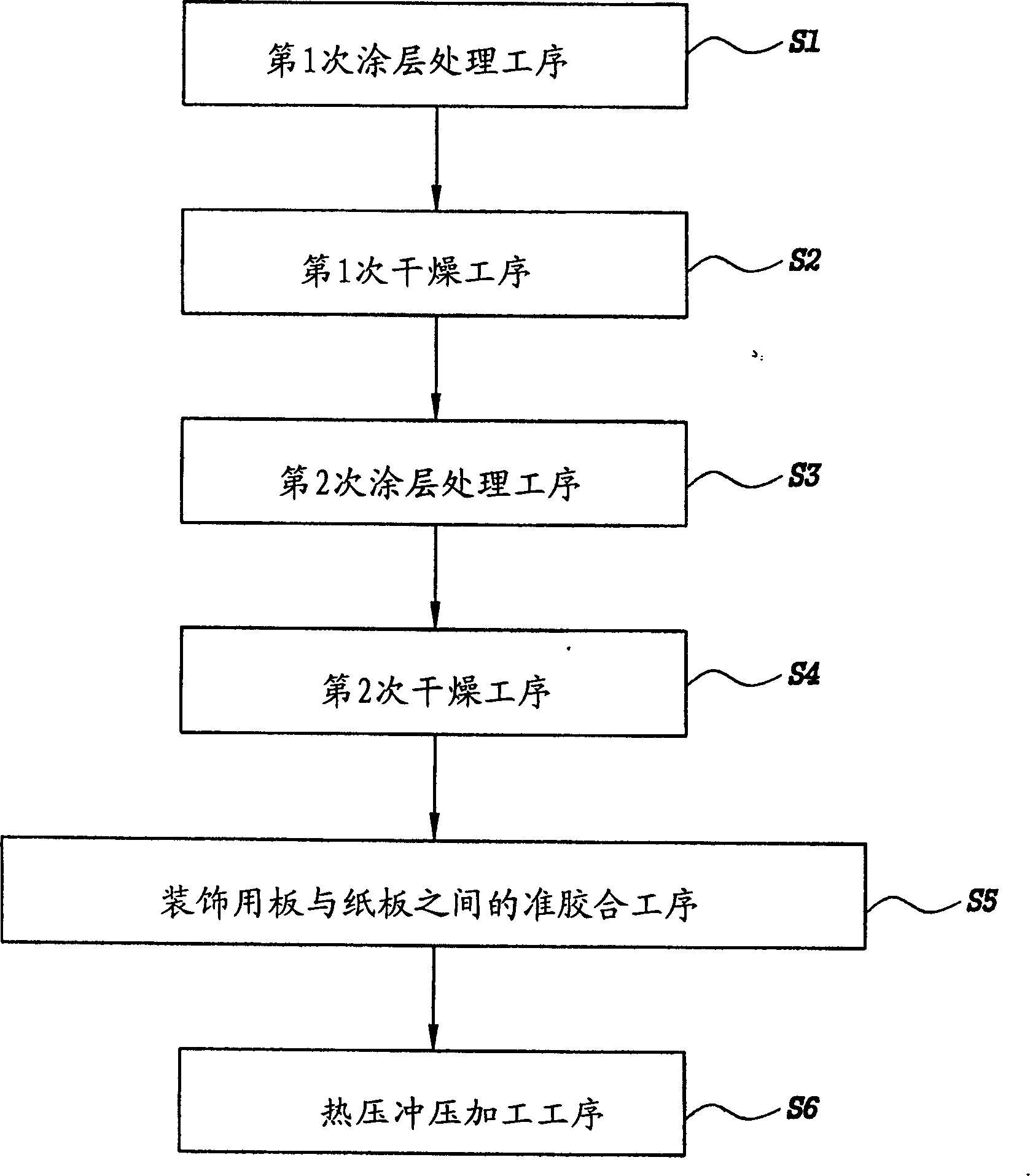

[0046] figure 1 is a flow chart showing the process of the present invention. Below, based on figure 1 The process of the present invention will be described.

[0047] (1st process - 1st coating treatment process: S1)

[0048] First of all, in order to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com