Method of two-way stretch for producing polystyrene film pump pipe

A technology of polystyrene film and production method, which is applied in the production field of biaxially oriented polystyrene film, can solve problems such as difficult formulation, difficult adjustment of production process, tight supply of raw materials, etc., and achieves high shrinkage rate and elastic modulus Great effect of saving foreign exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

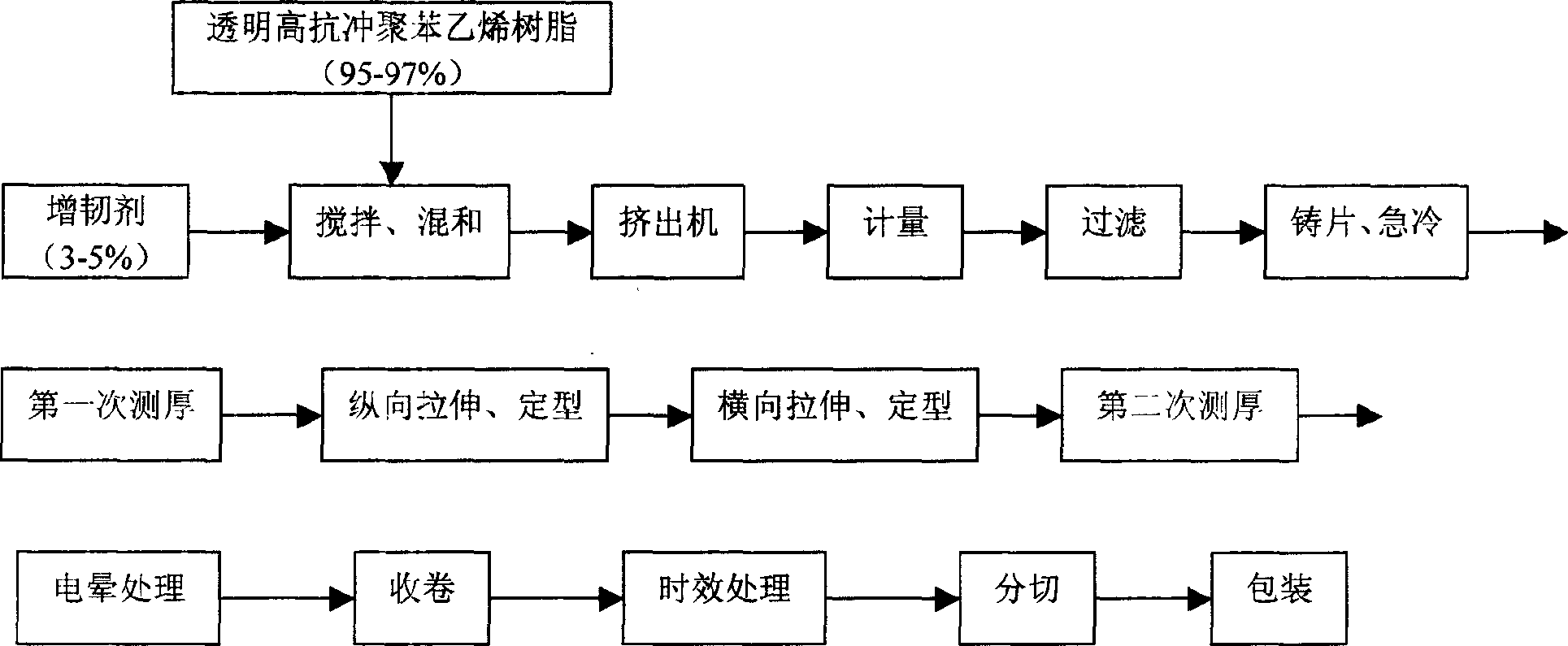

Image

Examples

Embodiment Construction

[0008] Below, the present invention is further described with reference to examples.

[0009] 147 kilograms of transparent high-impact polystyrene resin and 3 kilograms of toughening agent were fully stirred and mixed on a mixer for 15 minutes; the above-mentioned mixture was fed into an extruder called twin-screw vacuum exhaust and melted. , extrusion, the melting temperature is controlled between 210 °C and 230 °C; through the precise metering and filtration of the gear pump, the melt is sent to the T-die for extrusion, cast into thick sheets, and the first thickness measurement is carried out at the same time. , the thickness of the thick sheet is controlled between 1.5 mm and 4.0 mm; the thick sheet is preheated on a longitudinal drawing machine, and the preheating temperature is controlled between 60 ° C and 80 ° C, and the stretching and shaping are performed at the same time; Preheating is carried out on the stretching machine, and the preheating temperature is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com