Conductivity on-line monitoring method in beer fermentation process

A fermentation process and beer fermentation technology, applied in the field of beer brewing, can solve problems such as high price, inability to apply large-scale production, and easy damage, and achieve the effects of improving the quality of finished products, accurate online monitoring, and saving technical management levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Experimental conditions: Take 11-degree wort from the saccharification workshop, heat it to boil, and then pass it through the whirlpool sedimentation tank for 30 minutes, and cool the wine with a thin-plate heat exchanger to a 100L fermenter. The amount of yeast added is 6‰. The oxygenation of the wort was 8ppm, and the temperature of the main fermentation was 10°C.

[0019] The monitoring steps are:

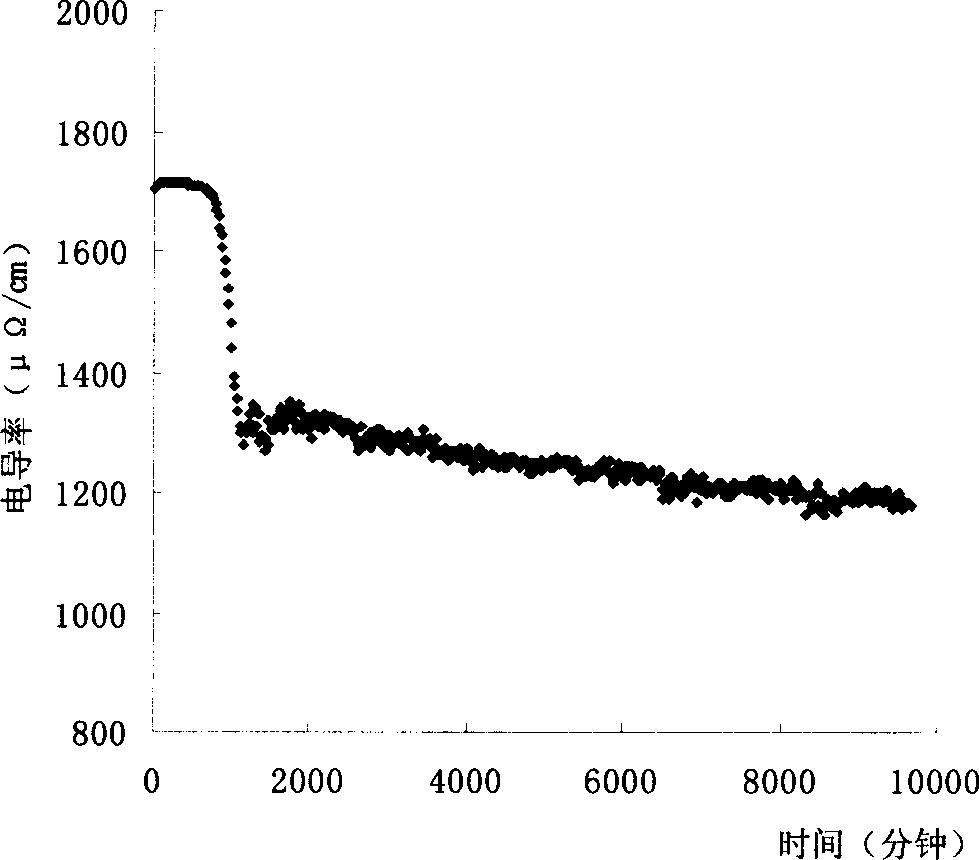

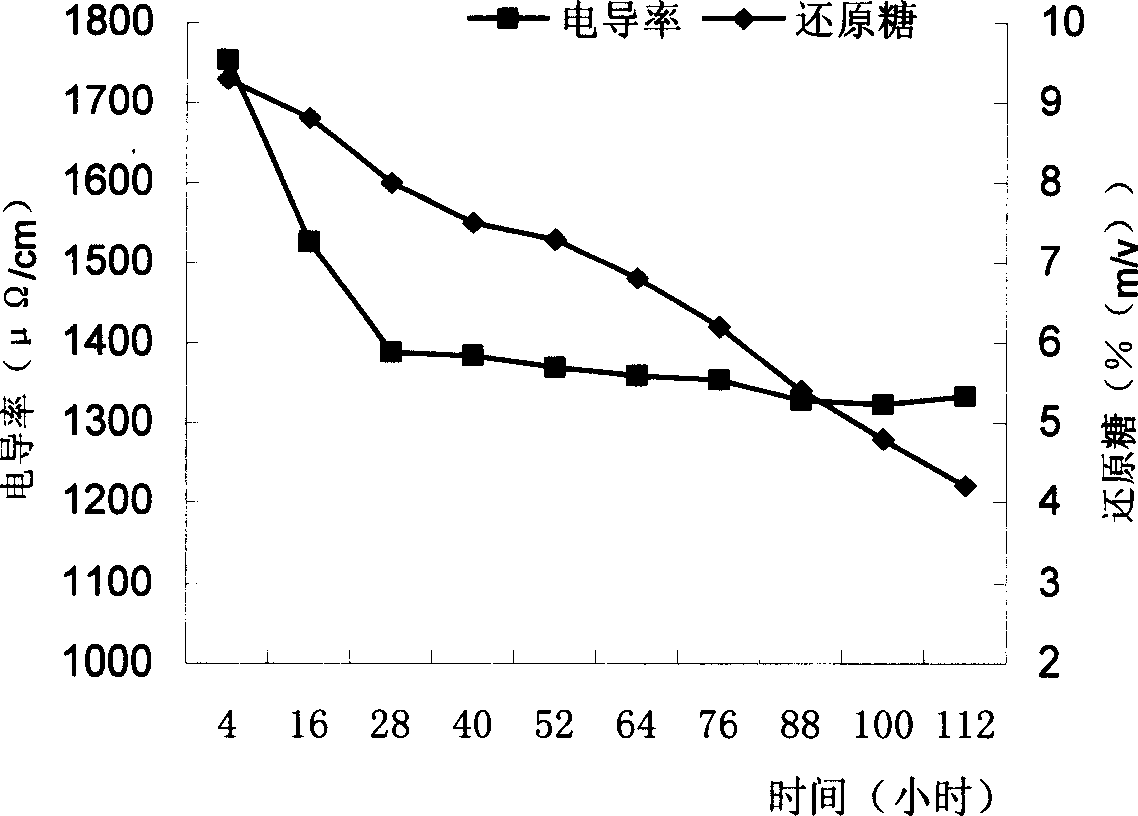

[0020] a. Use the acquisition system to collect a data point every 30 seconds to obtain the change in conductivity during the entire fermentation process. The average processing of the data is taken every 20 minutes, and the computer records the results as figure 1 . At the same time, synchronously detect reducing sugar, α-amino nitrogen or alcohol content in the fermenter, draw the contrast curve of conductivity and reducing sugar, α-amino nitrogen or alcohol content with fermentation time; figure 2 .

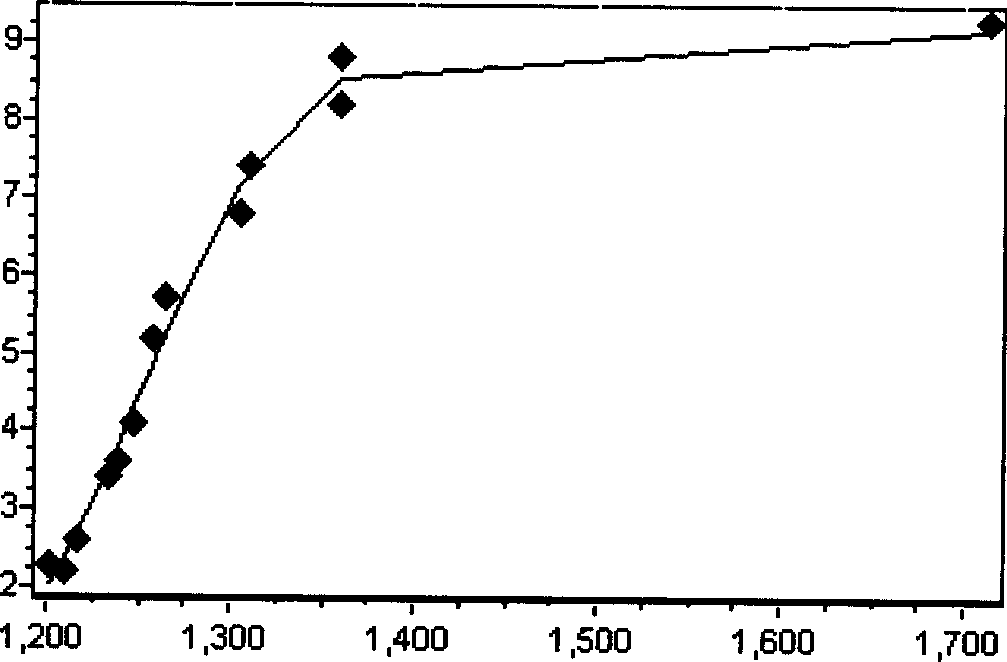

[0021] b. Using the least squares method and in conjunction w...

Embodiment 2

[0029] The 8-degree wort was taken from the saccharification workshop to conduct conductivity, reducing sugar, α-amino nitrogen or alcohol content detection, modeling and monitoring as in Example 1.

Embodiment 3

[0031] The 10-degree wort was taken from the saccharification workshop to conduct conductivity, reducing sugar, α-amino nitrogen or alcohol content detection, modeling and monitoring as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com