Method for preparing fine particles by making soft-shelled turtle egg as material

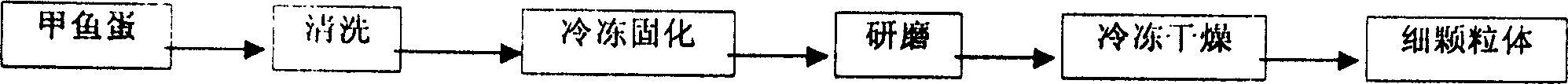

A technology of soft-shelled turtle eggs and fine particles, which is applied in the fields of preservation of eggs through freezing/cooling, food science, cocoa, etc. It can solve the problems of difficult absorption, unsmooth taste, and hard eggshell grinding, etc., so as to achieve easy digestion and good absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

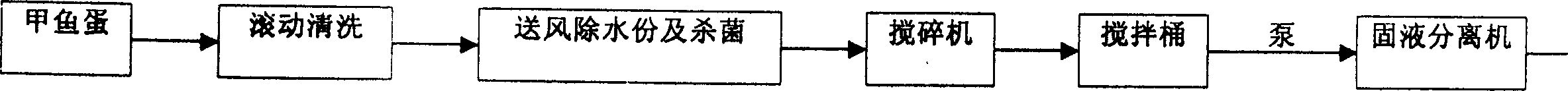

[0015] Such as figure 2 As shown, the present invention rolls and cleans a certain amount of soft-shelled turtle eggs first, and then utilizes a blower to dry the water content on the egg shells, so as not to increase the water content in the future due to the accumulated water content on the egg shells during manufacture. The water ratio when making granules, after that, put the soft-shelled turtle eggs into the pulverizer to break the soft-shelled turtle eggs, then put them into the mixing bucket to make the eggshells, egg whites and egg yolks in a liquid mixed state by stirring, and then put the The above-mentioned soft-shelled turtle egg mixture is pumped into the solid-liquid separator to complete the step of separating the hard eggshell from the liquid protein and egg yolk.

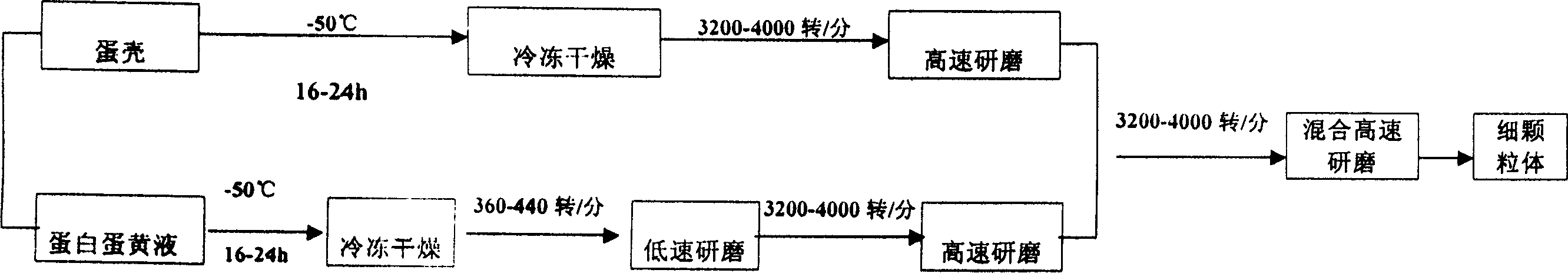

[0016] Secondly, put the separated eggshells, egg whites, and egg yolks into different containers, put them in the freezer at minus 50°C for about 20 hours, and freeze-dry them for about 20 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com