Preparation type electrochromatography separation arrangement with applied electric field being vertical to flow direction

A technology of separation equipment and vertical electric field, applied in the field of separation equipment of preparative electrochromatography, can solve the problems of large cooling load, high application voltage, product loss, etc., and achieve the effect of reducing energy consumption and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

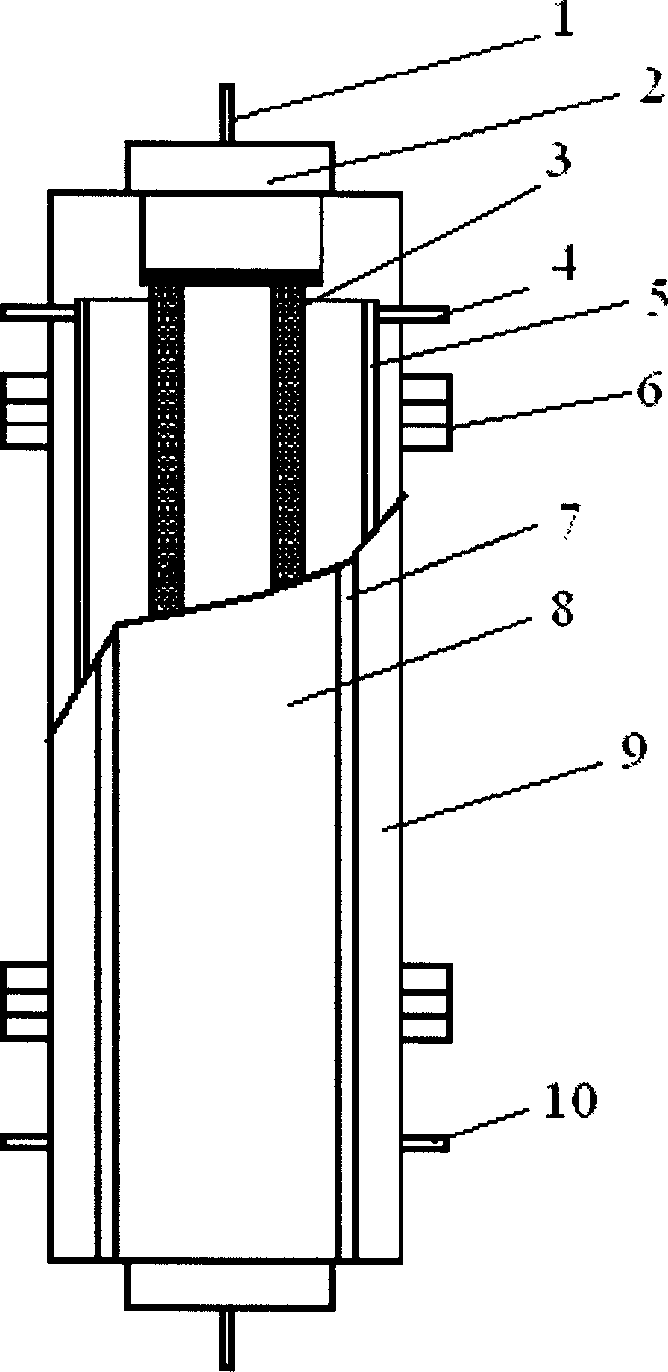

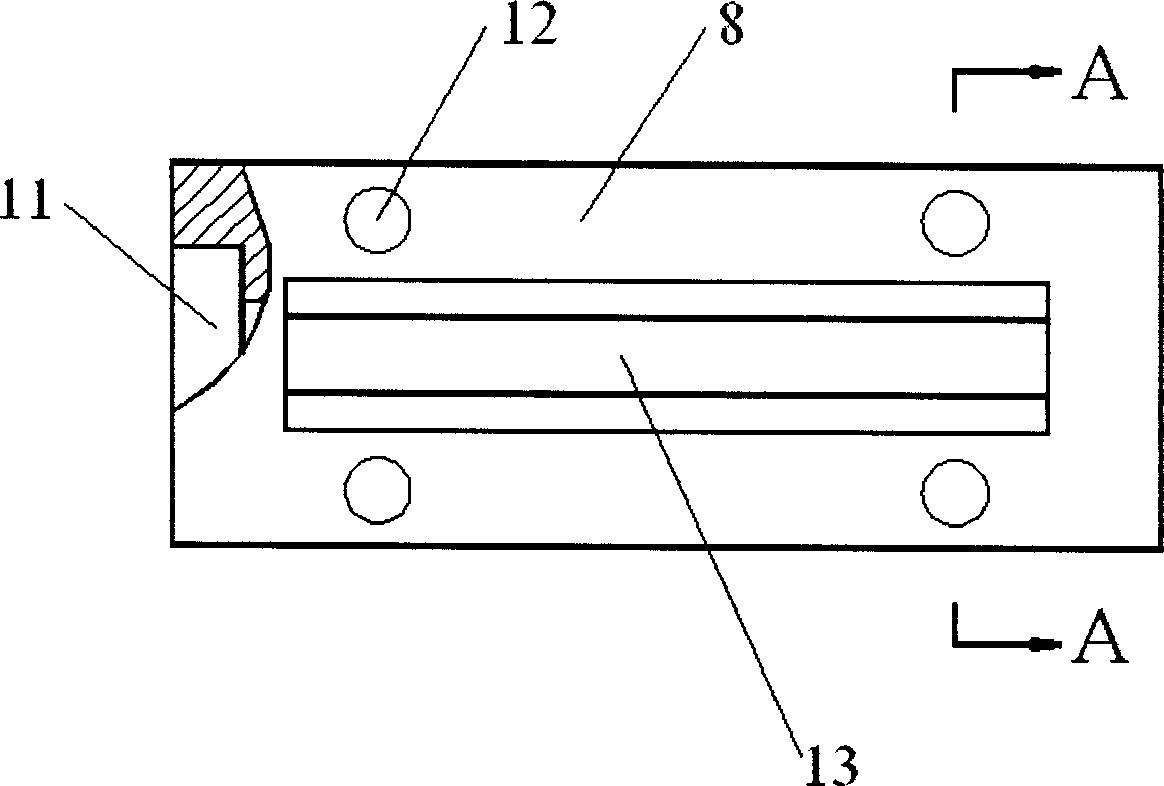

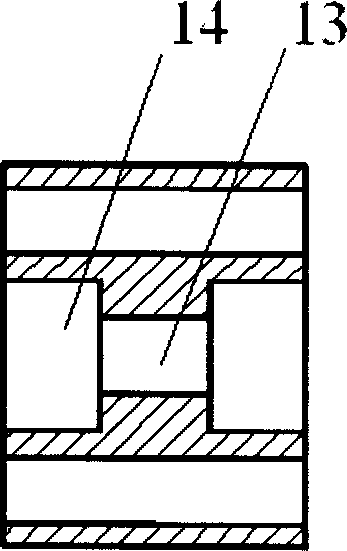

[0018] In the specific implementation process, the gel chamber 8, the membrane plate 3, the electrode chamber 9 and the gaskets are sequentially connected by the bolts and nuts 6 to form an integral chromatographic column. Due to the isolation of the diaphragm 3, the rectangular hollow structure of the middle gel compartment 8 (20.0 × 0.5 × 1.2 cm) forms a rectangular chromatographic column and is used to fill various types of chromatographic fillers, while the electrode compartments (20.1 × 0.8 cm) on both sides ×0.8cm) to form two symmetrical electrode chamber spaces corresponding to the gel chamber for introducing an external electric field. Platinum electrodes 5 are fixed around the electrode chamber and connected to a power source for generating a transverse electric field for electrochromatographic separation. The overall device size is 28.5×6.5×6.0cm. The operating procedure of the device is that the electrode liquid enters from the electrode liquid inlet 10 at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com