Method for removing CO2 from converted gas of two-stage pressure swing adsorption apparatus having a reclaiming unit

A pressure swing adsorption and recovery device technology, applied in the direction of adsorption, separation methods, chemical instruments and methods, etc., can solve the problem of large loss of effective gas, increase of surrounding environmental pollution and potential safety hazards, and reduction of the total output of synthetic ammonia, urea, and methanol and other problems, to achieve the effect of reducing power consumption, improving evacuation time and vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

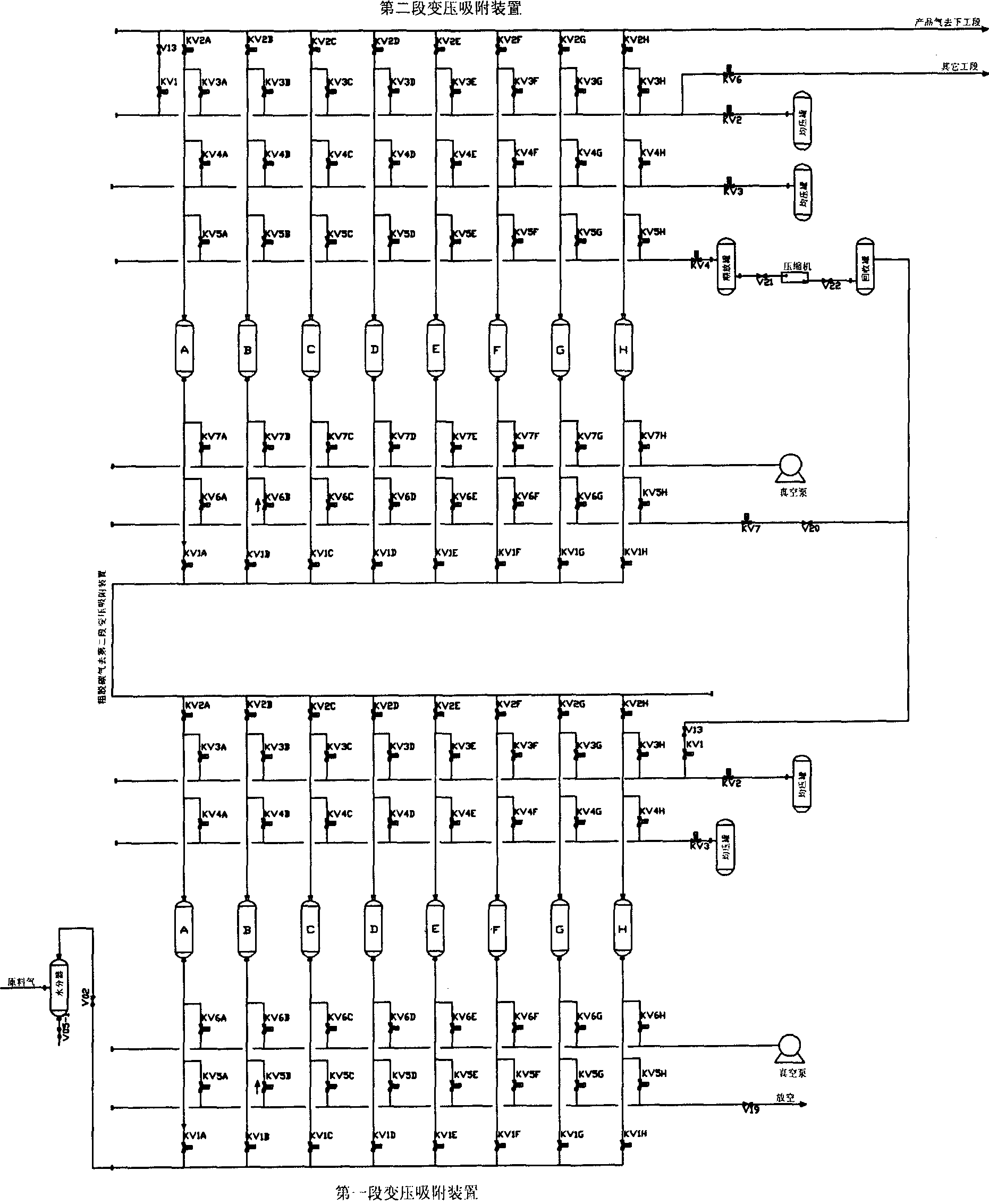

[0072] Removal of CO from synthetic ammonia by a two-stage pressure swing adsorption unit with recovery system 2 The method, which uses synthetic ammonia shift gas as raw material, achieves the removal of CO through two-stage pressure swing adsorption devices. 2 For the purpose, in this example, the first-stage pressure swing adsorption device does not need to purify and recover high-purity CO 2 .

[0073] 1. Implementation steps of the first stage pressure swing adsorption device

[0074] The raw material gas of the first-stage pressure swing adsorption device is the shift gas from the synthetic ammonia system, in which the temperature of the raw material gas is ≤40°C and the working pressure is 0.80MPa. The first-stage pressure swing adsorption device consists of eight adsorption towers and a steam-water separator 1. Two pressure equalizing tanks. The adsorber of this section of the device is equipped with three kinds of adsorbents: activated alumina, activated carbon and ...

Embodiment 2

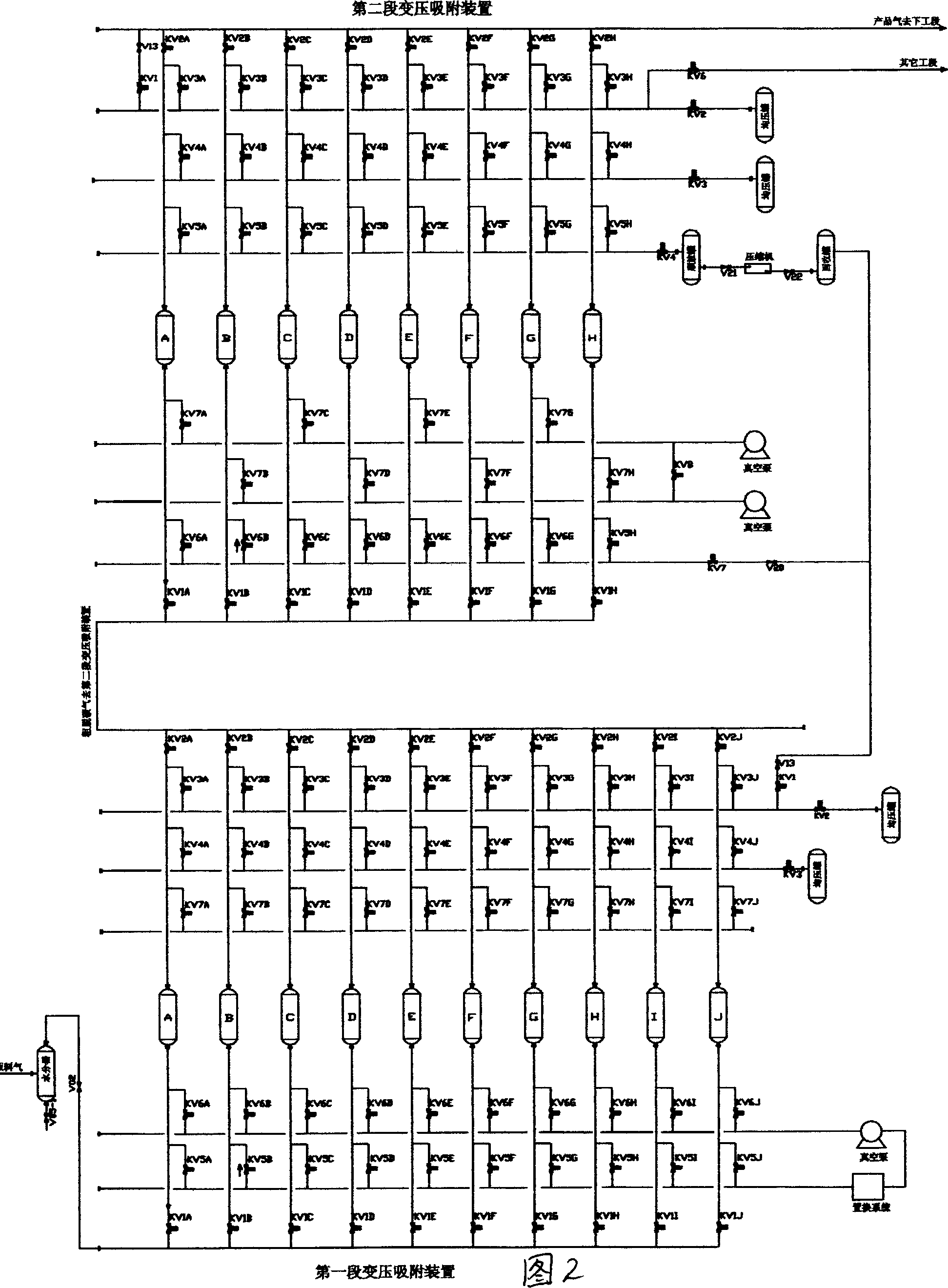

[0143] Removal of CO from synthetic ammonia by a two-stage pressure swing adsorption unit with recovery system 2 The method, which uses synthetic ammonia shift gas as raw material, achieves the removal of CO through two-stage pressure swing adsorption devices. 2 In this example, the first-stage pressure swing adsorption device needs to purify and recover high-purity 98.5% CO 2 For urea production.

[0144] 1. Implementation steps of the first stage pressure swing adsorption device

[0145] The raw material gas of the first-stage pressure swing adsorption device is the shift gas from the synthetic ammonia system, in which the temperature of the raw material gas is ≤40°C and the working pressure is 2.0MPa. The first-stage pressure swing adsorption device consists of ten adsorption towers and one steam-water separator 1. Two pressure equalizing tanks. The adsorber of this section of the device is equipped with three kinds of adsorbents: activated alumina, activated carbon and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com